While many hazards exist, the single most critical safety issue in welding, cutting, and brazing is exposure to toxic fumes, gases, and asphyxiants. Unlike the immediate and obvious dangers of burns or electric shock, these airborne contaminants are often invisible and can cause irreversible long-term health damage. This insidious nature makes proper ventilation and respiratory protection the most crucial and frequently overlooked aspect of welder safety.

The search for a single "most important" hazard is a natural but misleading way to approach safety. The true expert insight is that welding safety is not about avoiding one danger, but about implementing a comprehensive safety system that addresses all potential hazards—from atmospheric to electrical—simultaneously.

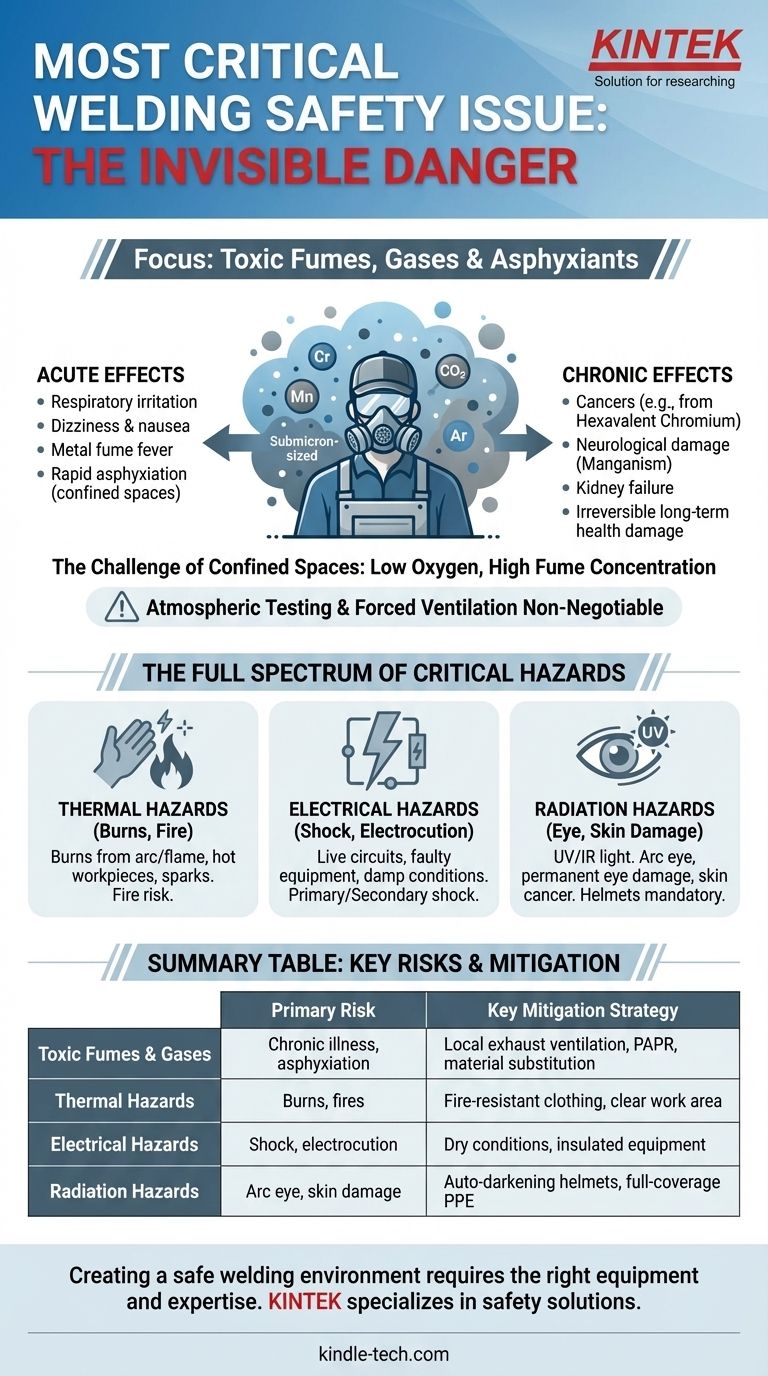

Why Fumes and Gases Are the Primary Concern

The immediate dangers of welding, like burns and fire, are visceral and easy to understand. However, the risks posed by the air you breathe are more complex and have severe consequences that can manifest hours or even decades later.

The Invisible Danger

Welding fumes are a complex mixture of metallic oxides, silicates, and fluorides. These submicron-sized particles can be inhaled deeply into the lungs. The specific composition depends on the welding process, the base metal, any coatings (paint, galvanizing), and the filler metals used.

Acute vs. Chronic Effects

Exposure carries both immediate and long-term risks.

- Acute effects can include respiratory irritation, dizziness, nausea, and metal fume fever. In confined spaces, shielding gases like argon or CO2 can displace oxygen, leading to rapid asphyxiation (suffocation).

- Chronic effects are the most serious. Long-term exposure to specific compounds like hexavalent chromium (from stainless steel) and manganese is linked to various cancers, neurological damage (Manganism, similar to Parkinson's disease), and kidney failure.

The Challenge of Confined Spaces

In any poorly ventilated or confined area, the risks multiply. Shielding gases can quickly lower oxygen levels to a fatal point, and fume concentrations can become dangerously high in minutes. This makes atmospheric testing and forced ventilation non-negotiable in these environments.

The Full Spectrum of Critical Hazards

While fumes are the most insidious threat, a holistic safety plan must account for all major risk categories. Ignoring any one of these can be just as deadly.

Thermal Hazards: Burns and Fire

This is the most common and obvious welding injury. It includes burns from the arc or flame, contact with hot workpieces, and sparks or spatter landing on skin. Beyond personal injury, these same sparks are a primary ignition source for fires, making a clean, non-flammable work area essential.

Electrical Hazards: Shock and Electrocution

Arc welding processes require live electrical circuits. Electrocution can occur from simultaneous contact with the electrode and the workpiece (secondary voltage shock) or from touching a part of a faulty welder (primary voltage shock). The risk is significantly higher in damp or wet conditions.

Radiation Hazards: Damage to Eyes and Skin

A welding arc produces intense ultraviolet (UV), infrared, and visible light. Even brief exposure can cause a painful condition known as "arc eye" or "welder's flash," which feels like having sand in your eyes. Chronic exposure increases the risk of permanent eye damage and skin cancer, which is why proper helmets and protective clothing are mandatory.

Understanding the Trade-offs: Complacency vs. Caution

In any production environment, there is a constant tension between safety protocols and the pressure to complete work quickly. This is where most safety failures originate.

The Normalization of Risk

Experienced welders can become complacent. Having performed a task hundreds of times without incident, they may be tempted to skip a step, like putting on a respirator for a "quick tack weld" or not moving a nearby flammable object. This normalization of deviance is a significant organizational risk.

The Cost and Comfort of Controls

Proper safety equipment, especially high-quality ventilation systems (like fume extractors) and powered air-purifying respirators (PAPRs), represents a significant cost. Furthermore, wearing full personal protective equipment (PPE) can be hot and cumbersome, creating a temptation to forego it in the name of comfort.

Making the Right Choice for Your Goal

Your approach to mitigating these risks depends on your role and responsibilities.

- If your primary focus is personal safety as an operator: Always prioritize respiratory protection and full-coverage PPE. Verify your work area is free of flammables and ensure ventilation is active before you ever strike an arc.

- If your primary focus is managing a safe workshop: Your priority is implementing engineering controls. This means investing in and enforcing the use of local exhaust ventilation (fume extractors) as the first line of defense, supplemented by a mandatory PPE policy.

- If your primary focus is designing a process or facility: Your goal is elimination and substitution. Design workflows that minimize welding in confined spaces and specify materials that produce less toxic fumes wherever possible.

Ultimately, a safe work environment is the direct result of a consistent and disciplined commitment to established safety principles.

Summary Table:

| Critical Welding Hazard | Primary Risk | Key Mitigation Strategy |

|---|---|---|

| Toxic Fumes & Gases | Chronic illness (cancer, neurological damage), acute asphyxiation | Local exhaust ventilation, respiratory protection (PAPR), material substitution |

| Thermal Hazards | Burns, fires | Fire-resistant clothing, clear work area, spark containment |

| Electrical Hazards | Shock, electrocution | Dry conditions, insulated equipment, proper grounding |

| Radiation Hazards | Arc eye, skin damage | Auto-darkening helmets, full-coverage protective clothing |

Creating a safe welding environment requires the right equipment and expertise. KINTEK specializes in providing laboratory and industrial safety solutions, including fume extraction systems and PPE, to protect your team from hazardous exposures. Don't compromise on safety—contact our experts today to assess your needs and implement a comprehensive safety plan tailored to your operations.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Special Heat Press Mold for Lab Use

- Custom PTFE Teflon Parts Manufacturer for PTFE Tweezers

- Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

- 304 316 Stainless Steel Vacuum Ball Valve Stop Valve for High Vacuum Systems

People Also Ask

- What is vacuum lamination? Achieve a Flawless, Durable Finish on Complex Shapes

- What is the advantage by using hot press forming? Achieve Stronger, More Complex Parts

- What is hot press moulding? Achieve Superior Density and Complex Shapes with Heat and Pressure

- What is hot press lamination? The Ultimate Guide to Strong, Durable Material Bonding

- What is the main function of hot press forming? Achieve Superior Strength & Precision in Manufacturing