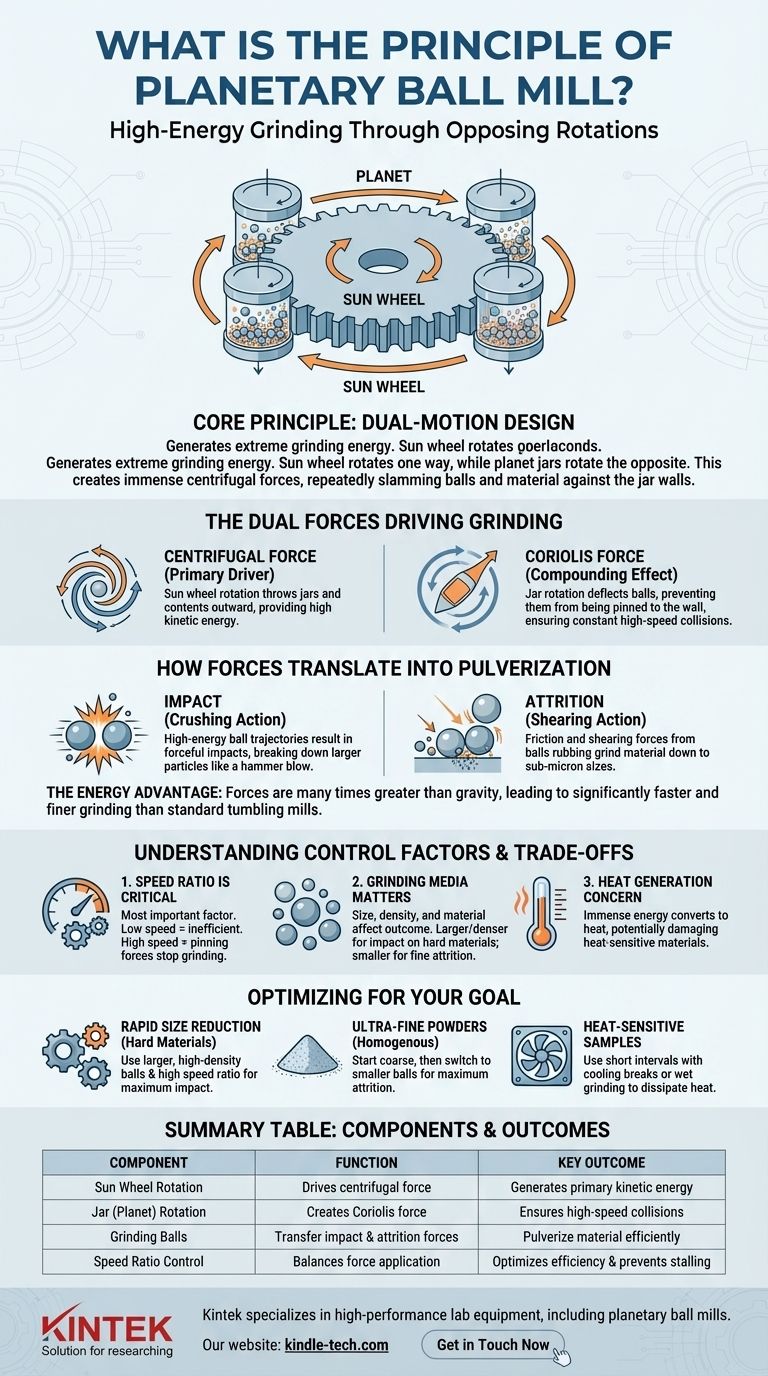

At its core, the principle of a planetary ball mill is the generation of extremely high grinding energy through a system of opposing rotations. A central "sun wheel" rotates in one direction, while the grinding jars, or "planets," mounted on it are forced to rotate on their own axes in the opposite direction. This dual-motion design creates immense centrifugal forces that repeatedly slam grinding balls and sample material against the inside of the jar.

The key insight is that a planetary ball mill doesn't just tumble material like a simple mill; its unique counter-rotating mechanism generates powerful impact and attrition forces. This high-energy environment is what enables rapid pulverization of materials down to very fine, often sub-micron, particle sizes.

The Dual Forces Driving the Grinding Action

The effectiveness of a planetary ball mill comes from two distinct forces that are superimposed on each other, creating a complex and highly energetic grinding environment inside the jar.

Centrifugal Force: The Primary Driver

The main rotation of the sun wheel creates a powerful centrifugal force. This force constantly tries to throw the grinding jar, and everything inside it, away from the center of rotation. This is the primary source of the system's high kinetic energy.

Coriolis Force: The Compounding Effect

As the jar rotates on its own axis in the opposite direction, it generates a secondary force known as the Coriolis force. This force acts on the grinding balls, preventing them from simply being pinned against the outer wall of the jar. Instead, it causes the balls to be lifted and thrown across the interior, ensuring constant, high-speed collisions.

How Forces Translate into Pulverization

The combination of centrifugal and Coriolis forces translates into two critical grinding mechanisms that work in tandem to break down materials.

Impact: The Crushing Action

The high-energy trajectories of the grinding balls result in forceful impacts. Balls are flung across the jar at high speed, striking the material and the opposite jar wall. This is a powerful crushing action, similar to a hammer blow, that is responsible for the rapid breakdown of larger particles.

Attrition: The Shearing Action

As the balls roll and slide against each other and the inner wall of the jar, they create immense friction and shearing forces. This attrition grinds material down through rubbing and is highly effective at producing extremely fine particles once the initial impact phase is complete.

The Energy Advantage

In a standard tumbling ball mill, the grinding action is driven primarily by gravity as the cylinder rotates. A planetary ball mill's forces are many times greater than gravity, leading to significantly faster and finer grinding results.

Understanding the Trade-offs and Control Factors

While powerful, the planetary mill is not a one-size-fits-all solution. Its effectiveness depends on carefully controlling its operational parameters.

Speed Ratio is Critical

The ratio of rotation speed between the sun wheel and the grinding jars is the most important control factor. If the speed is too low, grinding is inefficient. If it's too high, centrifugal force can pin the balls and material to the wall, ceasing the impacts and stopping the grinding process.

Grinding Media Matters

The size, density, and material of the grinding balls have a direct effect on the outcome. Larger, denser balls create higher impact forces for breaking down hard materials. Smaller balls increase the frequency of collisions and the surface area for attrition, ideal for achieving a very fine final product.

Heat Generation is a Major Concern

The immense energy input of a planetary mill is largely converted into heat. This can be detrimental to heat-sensitive materials, potentially causing them to melt, decompose, or change their crystalline structure. This is a fundamental trade-off of high-energy milling.

Optimizing the Mill for Your Goal

Controlling the forces inside the mill is the key to achieving your desired result. A few guiding principles can help you make the right choice for your application.

- If your primary focus is rapid size reduction of hard materials: Use larger, high-density grinding balls (like tungsten carbide) and a high speed ratio to maximize impact forces.

- If your primary focus is producing ultra-fine, homogenous powders: Start with a coarse grind, then switch to smaller grinding balls to maximize the effects of attrition and friction.

- If your primary focus is grinding a heat-sensitive sample: Use shorter grinding intervals with cooling breaks in between, or consider wet grinding, where a liquid medium helps dissipate the excess heat.

Ultimately, mastering the planetary ball mill comes from understanding how to manipulate its powerful forces to match your specific material and target particle size.

Summary Table:

| Principle Component | Function | Key Outcome |

|---|---|---|

| Sun Wheel Rotation | Drives centrifugal force | Generates primary kinetic energy |

| Jar (Planet) Rotation | Creates Coriolis force | Ensures high-speed ball collisions |

| Grinding Balls | Transfer impact & attrition forces | Pulverize material efficiently |

| Speed Ratio Control | Balances force application | Optimizes grinding efficiency & prevents stalling |

Ready to Optimize Your Sample Preparation?

Understanding the principle of a planetary ball mill is the first step to achieving superior results in your lab. Whether you need to pulverize hard materials rapidly or produce ultra-fine, homogenous powders, the right equipment is critical.

KINTEK specializes in high-performance lab equipment and consumables, including planetary ball mills designed for precision, durability, and maximum grinding efficiency. Our experts can help you select the ideal mill and grinding media to match your specific material and particle size goals.

Contact us today to discuss your application and discover how KINTEK can enhance your laboratory's capabilities.

Visual Guide

Related Products

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill for Laboratory Horizontal Tank Type Milling Machine

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

People Also Ask

- What are the factors affecting the performance of a ball mill? Optimize Your Grinding Efficiency

- What is the role of a high-energy ball mill in Ti-based amorphous composite preparation? Master Mechanical Alloying

- How do you calculate ball mill load? Optimize Grinding Efficiency and Reduce Costs

- What are the factors that can influence the size reduction process of a ball mill? Master Speed, Media, and Material for Optimal Grinding

- Why are zirconia grinding jars and balls selected for sulfide solid electrolytes? Ensure High Ionic Conductivity

- What is the role of a ball mill and corundum grinding balls in boron carbide ceramic preparation? Ensure High Purity

- Why are zirconia (ZrO2) grinding balls and jars preferred for Li3PS4-LiI glass electrolytes? Ensure Purity & Performance

- How does a high-energy centrifugal ball mill help synthesize magnesium composites? Unlock Rapid Hydrogen Production