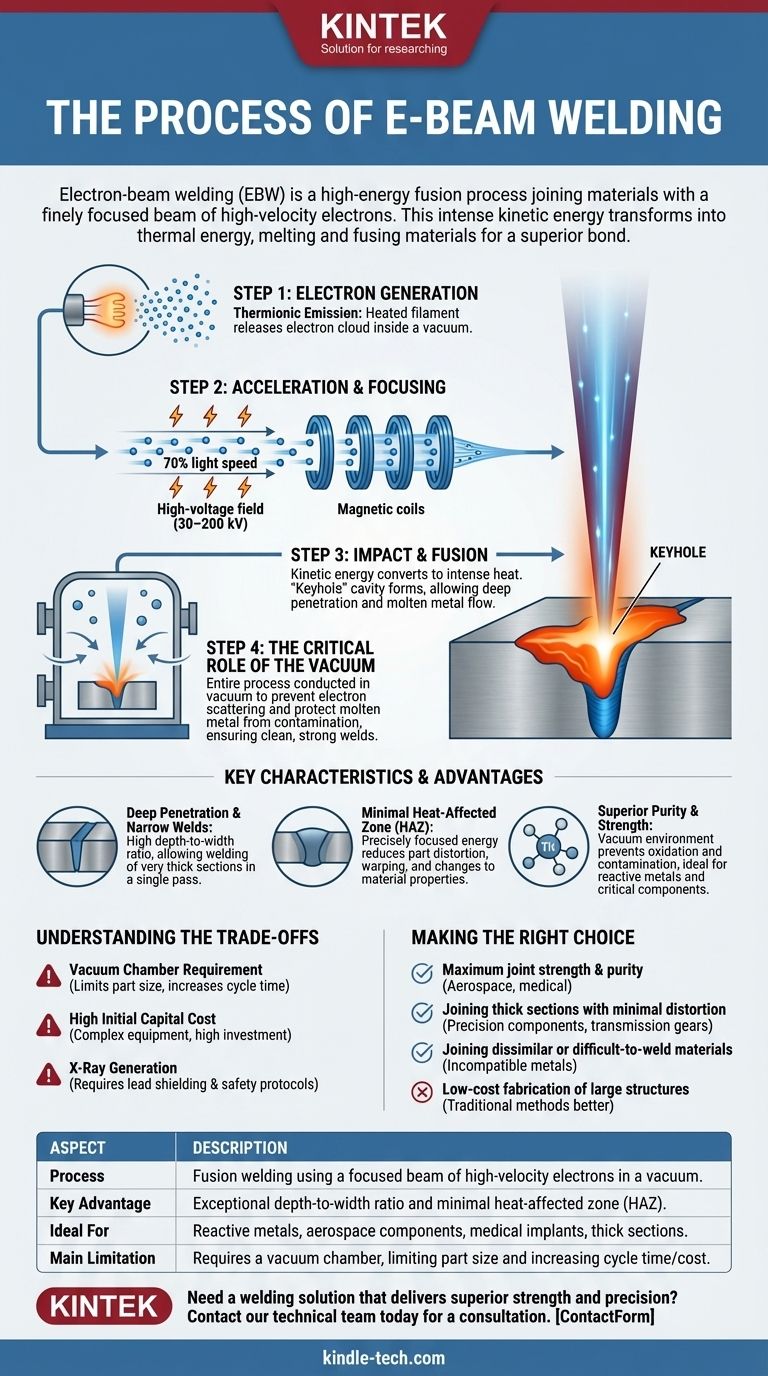

At its core, electron-beam welding (EBW) is a high-energy fusion process that joins materials by striking them with a finely focused beam of high-velocity electrons. This intense concentration of kinetic energy instantly transforms into thermal energy upon impact, melting the materials and allowing them to fuse together as they cool, creating a superior metallurgical bond.

The true advantage of EBW isn't just the heat, but the incredible density and precision of that heat. By operating in a vacuum, the process delivers highly concentrated energy deep into the material, creating welds that are impossible to achieve with conventional methods.

The Core Mechanism: From Electron to Weld

Understanding the EBW process requires looking at how a stream of electrons is generated, accelerated, and controlled to perform work. Each step is critical to achieving the final result.

Step 1: Electron Generation

The process begins with a filament, typically made of tungsten, which is heated to extreme temperatures inside a vacuum. This intense heat causes the filament to release a cloud of electrons in a process known as thermionic emission.

Step 2: Acceleration and Focusing

These free electrons are then subjected to a powerful electric field created by a high-voltage potential (often between 30 and 200 kilovolts). This voltage difference accelerates the electrons to tremendous speeds, up to 70% the speed of light.

As the electrons travel down the beam column, a series of magnetic coils act like lenses, precisely focusing the stream into a very fine, high-density spot.

Step 3: Impact and Fusion

When this highly focused beam of electrons strikes the workpiece, its immense kinetic energy is converted into an intense, localized heat. The power density is so high that it vaporizes the material at the point of impact, creating a deep cavity known as a "keyhole."

This keyhole allows the energy to penetrate deeply into the material. As the beam moves along the joint, molten metal flows in behind it to fill the cavity, solidifying to form a very deep and narrow weld.

Step 4: The Critical Role of the Vacuum

The entire process is conducted within a vacuum chamber for two essential reasons. First, the vacuum prevents the accelerated electrons from colliding with and scattering off air molecules, which would diffuse the beam and rob it of its power.

Second, the vacuum environment protects the molten metal from atmospheric contaminants like oxygen and nitrogen, ensuring an exceptionally clean, pure, and strong weld free of impurities.

Key Characteristics and Advantages

The unique physics of the EBW process gives it several distinct advantages over traditional welding techniques.

Deep Penetration and Narrow Welds

The keyhole effect allows EBW to produce welds with a very high depth-to-width ratio. This means you can join very thick sections of material in a single pass, which is far more efficient than the multiple passes required by conventional methods.

Minimal Heat-Affected Zone (HAZ)

Because the energy is so precisely focused, very little excess heat spreads into the surrounding material. This results in a tiny Heat-Affected Zone (HAZ), drastically reducing part distortion, warping, and changes to the material's properties.

Superior Purity and Strength

Welding within a vacuum eliminates the possibility of oxidation and contamination. This produces welds of exceptional purity and strength, making the process ideal for joining reactive metals like titanium or performance-critical components.

Understanding the Trade-offs

While powerful, EBW is not the solution for every application. Its primary limitations are a direct result of the equipment and environment it requires.

The Vacuum Chamber Requirement

Parts must fit inside a vacuum chamber. This limits the size of the components that can be welded and adds to the overall cycle time, as the chamber must be pumped down to a vacuum for each batch.

High Initial Capital Cost

Electron-beam welding systems are complex and require a significant capital investment compared to standard welding equipment like TIG or MIG. This often makes it best suited for high-value or high-volume production.

X-Ray Generation

The impact of high-energy electrons on metal inherently produces X-rays. This requires the equipment to be built with lead shielding and for operators to follow strict safety protocols, adding to the system's complexity and cost.

Making the Right Choice for Your Goal

Selecting EBW depends entirely on the specific technical requirements of your component and production goals.

- If your primary focus is maximum joint strength and purity: EBW is an excellent choice for reactive metals or components where weld integrity is a matter of safety, such as in aerospace or medical implants.

- If your primary focus is joining thick sections with minimal distortion: EBW is superior for manufacturing precision components like transmission gears, where maintaining tight dimensional tolerances is critical.

- If your primary focus is joining dissimilar or difficult-to-weld materials: The precise control and high energy density of EBW can successfully join metals that are incompatible with other welding processes.

- If your primary focus is low-cost fabrication of large structures: The vacuum chamber size limitations and high capital cost make EBW unsuitable; traditional methods like MIG or submerged arc welding are better.

Ultimately, electron-beam welding offers a level of precision, depth, and purity that conventional welding processes cannot match.

Summary Table:

| Aspect | Description |

|---|---|

| Process | Fusion welding using a focused beam of high-velocity electrons in a vacuum. |

| Key Advantage | Exceptional depth-to-width ratio and minimal heat-affected zone (HAZ). |

| Ideal For | Reactive metals (e.g., titanium), aerospace components, medical implants, and thick sections. |

| Main Limitation | Requires a vacuum chamber, limiting part size and increasing cycle time/cost. |

Need a welding solution that delivers superior strength and precision?

Electron-beam welding is ideal for high-value components where joint integrity, minimal distortion, and material purity are non-negotiable. If you work with reactive metals, thick sections, or performance-critical parts for the aerospace, medical, or automotive industries, this process can be a game-changer for your manufacturing.

At KINTEK, we specialize in advanced laboratory and manufacturing equipment. Let our experts help you determine if e-beam welding is the right solution for your specific materials and project goals.

Contact our technical team today for a consultation and discover how we can support your precision welding needs.

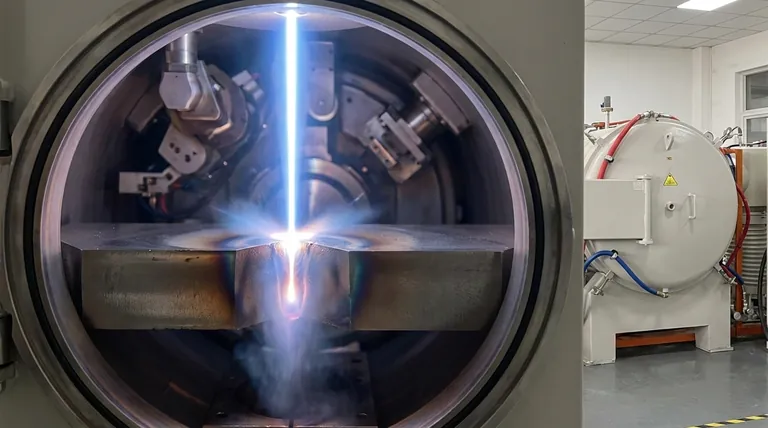

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

- Vacuum Dental Porcelain Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What happens to heat generated in a vacuum? Mastering Thermal Control for Superior Materials

- What are the most commonly used metals in a vacuum furnace's hot zone? Discover the Key to High-Purity Processing

- What is the process of a vacuum furnace? Achieve Purity and Precision in High-Temp Processing

- What is the advantage of furnace brazing? Achieve Strong, Clean Joints with Minimal Distortion

- What materials are used in a vacuum furnace? A Guide to Hot Zone Materials and Processed Metals