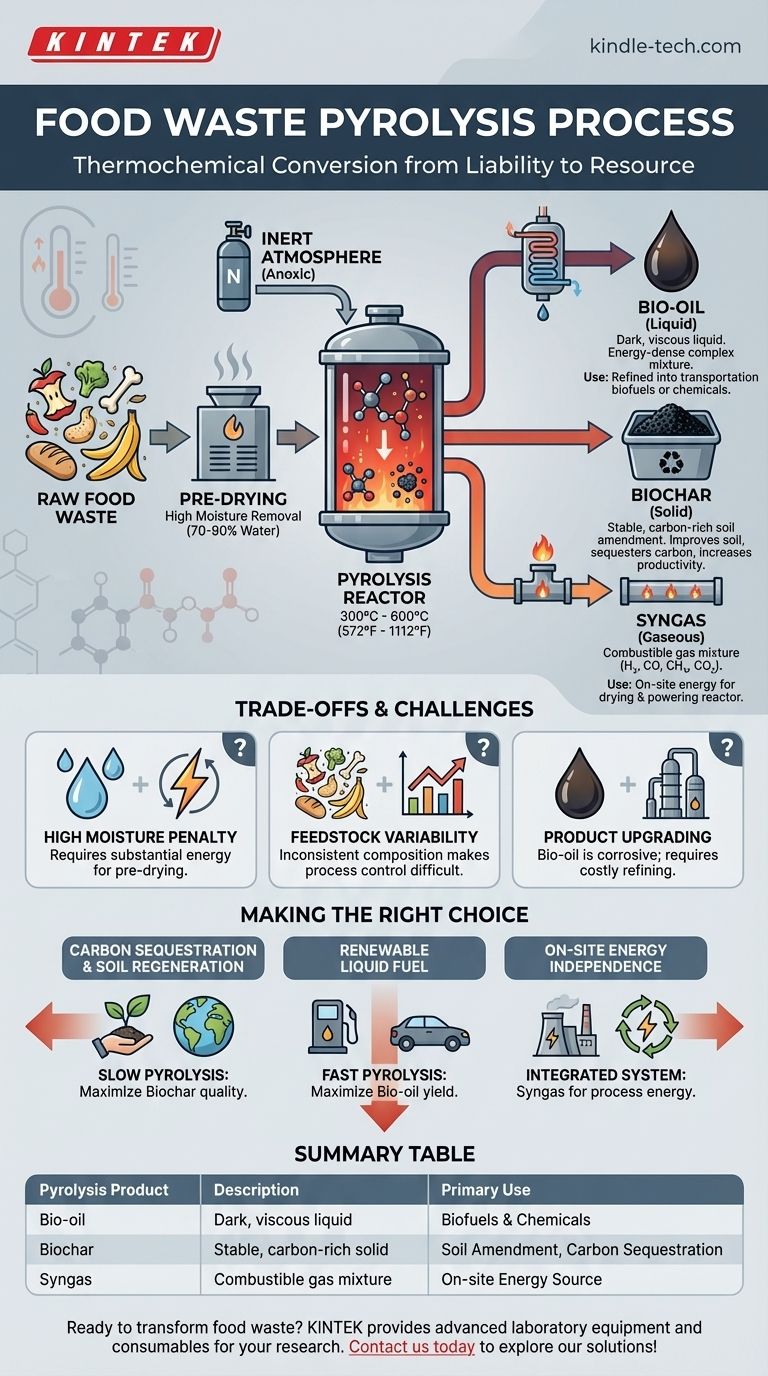

At its core, pyrolysis is a thermochemical treatment process that decomposes food waste using high heat in a completely oxygen-free environment. Instead of burning the waste, this process breaks it down into three distinct and valuable products: a liquid known as bio-oil, a solid carbon-rich material called biochar, and a combustible gas called syngas.

The crucial insight is that pyrolysis is not simply a disposal method—it is a conversion technology. It transforms the problem of food waste into an opportunity by upgrading a low-value liability into valuable energy carriers and materials.

The Core Mechanism: How Pyrolysis Works

Pyrolysis is fundamentally a process of thermal decomposition. By removing oxygen, we prevent combustion and force the complex organic molecules within the food waste to break apart under the stress of high heat.

The Role of Heat and Inert Atmosphere

The entire process takes place inside a sealed reactor. This reactor is heated to temperatures typically ranging from 300°C to 600°C (572°F to 1112°F).

An inert gas, like nitrogen, is used to purge all oxygen from the reactor. This oxygen-free (anoxic) condition is the defining characteristic of pyrolysis and is critical for ensuring the waste decomposes rather than burns.

From Waste to Valuable Products

As the food waste heats up, the long-chain organic polymers (carbohydrates, proteins, fats) become unstable and break down into smaller, simpler molecules.

The volatile components vaporize and are channeled out of the reactor. These vapors are then rapidly cooled and condensed to form liquid bio-oil.

The non-volatile, carbon-heavy fraction remains in the reactor as a solid, porous material: biochar. The non-condensable gases that are left over constitute the syngas.

The Outputs: A Portfolio of Resources

The true value of pyrolysis lies in the utility of its products. The specific yield of each product can be controlled by adjusting the process parameters.

Bio-oil (Liquid Fraction)

Bio-oil is a dark, viscous liquid sometimes called pyrolysis oil. It is an energy-dense but complex mixture of oxygenated organic compounds.

It can be refined into transportation biofuels or other valuable chemicals, though it often requires significant upgrading due to its acidity and instability.

Biochar (Solid Fraction)

Biochar is a stable, carbon-rich solid similar to charcoal. Its primary value is as a soil amendment.

Adding biochar to soil can improve water retention, reduce nutrient leaching, and increase agricultural productivity. Crucially, it sequesters carbon in the soil for hundreds of years, making it a powerful carbon-negative technology.

Syngas (Gaseous Fraction)

Syngas is a mixture of combustible gases, primarily hydrogen (H₂), carbon monoxide (CO), methane (CH₄), and carbon dioxide (CO₂).

Its most practical use is to be recycled back into the system. It can be combusted on-site to generate the heat required for drying the incoming food waste and powering the pyrolysis reactor, making the process partially self-sustaining.

Understanding the Trade-offs and Challenges

While powerful, pyrolysis for food waste is not without significant technical and economic hurdles that demand objective consideration.

The High Moisture Hurdle

Food waste often contains 70-90% water. This moisture must be removed before pyrolysis can occur, which requires a substantial amount of energy.

This pre-drying step represents a major energy penalty and is often the biggest challenge to the economic viability of a food waste pyrolysis plant.

Feedstock Variability

Unlike uniform feedstocks like wood chips, food waste is highly heterogeneous. Its composition changes daily based on source and season.

This variability can make it difficult to maintain stable operating conditions and produce consistent, high-quality end products without advanced sorting and mixing protocols.

Product Upgrading and Market Access

Bio-oil is not a "drop-in" fuel. It is corrosive and chemically unstable, requiring costly hydrotreating or other refining processes before it can be used as a replacement for conventional fuels.

Similarly, markets for biochar are still developing, and profitability often depends on local demand and the ability to monetize its carbon sequestration value.

Making the Right Choice for Your Goal

The optimal pyrolysis strategy depends entirely on your primary objective for treating food waste.

- If your primary focus is carbon sequestration and soil regeneration: Pursue slow pyrolysis (lower temperatures, longer processing times) to maximize the yield and quality of stable biochar.

- If your primary focus is renewable liquid fuel production: Pursue fast pyrolysis (higher temperatures, rapid heating) to maximize the yield of bio-oil for subsequent refining.

- If your primary focus is on-site energy independence and waste reduction: Design an integrated system where syngas provides the energy for the process, effectively closing the energy loop.

Ultimately, pyrolysis offers a sophisticated pathway to transform food waste from a liability into a portfolio of valuable, sustainable resources.

Summary Table:

| Pyrolysis Product | Description | Primary Use |

|---|---|---|

| Bio-oil | A dark, viscous liquid from condensed vapors | Can be refined into biofuels or chemicals |

| Biochar | A stable, carbon-rich solid residue | Soil amendment for carbon sequestration and fertility |

| Syngas | A mixture of combustible gases (H₂, CO, CH₄) | On-site energy source for process heating |

Ready to transform your food waste into valuable resources? KINTEK specializes in advanced laboratory equipment and consumables for pyrolysis research and development. Whether you're optimizing biochar production for soil health or refining bio-oil for energy, our solutions help you achieve precise, efficient results. Contact us today to explore how our expertise can support your sustainable waste conversion goals!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products