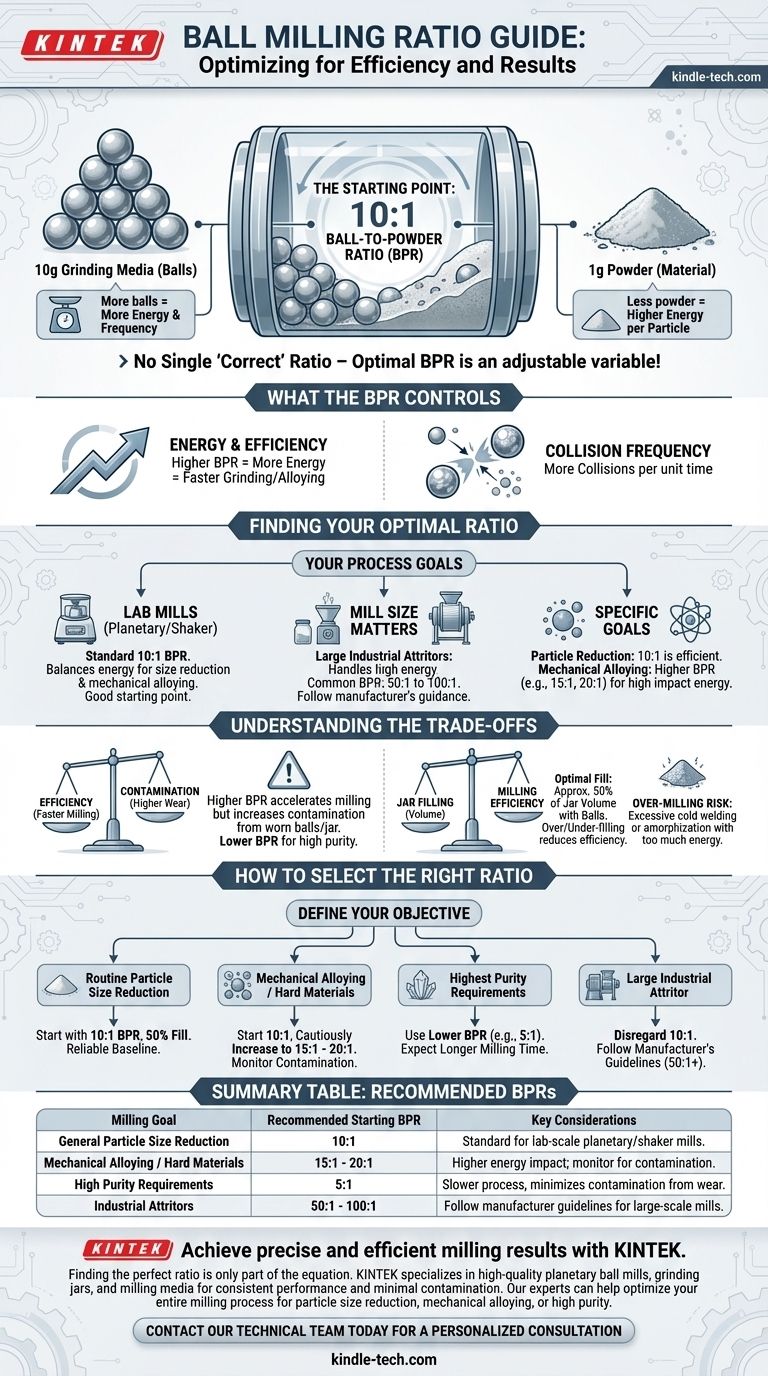

As a starting point, the most common ratio used in ball milling is a 10:1 Ball-to-Powder Ratio (BPR) by weight. This means for every 10 grams of grinding media (the balls), you would use 1 gram of the powder you intend to mill. This ratio is a well-established rule of thumb, particularly for smaller, lab-scale milling operations.

The concept of a single "correct" ratio is a misconception. The optimal Ball-to-Powder Ratio is not a fixed number but a critical variable that must be adjusted based on your specific equipment, materials, and desired outcome.

What the Ball-to-Powder Ratio Actually Controls

The ratio between your grinding media and your material is the primary lever you have to control the energy and efficiency of the milling process. Understanding what this ratio represents is key to achieving consistent results.

Defining the Core Ratio

The term "ratio" in this context almost always refers to the Ball-to-Powder Ratio (BPR). This is a simple calculation of the total mass of the grinding media (balls) divided by the total mass of the material or powder being processed.

Why the BPR is Critical

The BPR directly determines the energy imparted to your powder. A higher BPR means there are more balls relative to the powder, leading to more frequent and energetic collisions. This typically results in faster and more effective grinding or alloying.

Finding Your Optimal Ratio

While 10:1 is the standard starting point, it is not a universal constant. The ideal BPR for your process depends heavily on your specific goals and the type of equipment you are using.

The 10:1 Starting Point for Lab Mills

For most bench-top and small-capacity planetary or shaker mills (like those from SPEX), a 10:1 BPR provides an excellent balance. It delivers sufficient energy for effective particle size reduction and mechanical alloying without being excessively aggressive.

The Impact of Mill Size

Large-scale industrial mills, often called attritors, operate on a different principle and can handle much higher energy inputs. For these systems, BPRs of 50:1 or even 100:1 are common. The design of these mills is optimized to manage the heat and forces generated by such a high mass of grinding media.

The Goal of Your Milling

Your desired outcome is a major factor. Simple particle size reduction may be achieved efficiently at a standard 10:1 ratio. However, processes like mechanical alloying, where you are trying to force different elements to form a new alloy at the atomic level, often require higher impact energy and may benefit from a higher BPR.

Understanding the Trade-offs

Increasing the BPR is not a "free" gain in efficiency. It introduces critical trade-offs that you must manage to ensure the quality of your final product.

Efficiency vs. Contamination

This is the most important trade-off. A higher BPR accelerates milling but also increases the rate of wear on the grinding balls and the jar interior. This worn material will contaminate your powder. If you require very high purity, you may need to use a lower BPR over a longer time.

The Importance of Jar Filling

Beyond the BPR, the total volume inside the jar is critical. As a general rule, the grinding balls should fill approximately 50% of the jar's volume. The powder then fills the empty (interstitial) spaces between the balls. Over- or under-filling the jar will drastically reduce milling efficiency, regardless of the BPR.

The Risk of Over-Milling

Too much energy, from either an excessively high BPR or milling for too long, can be detrimental. It can lead to unwanted effects like excessive cold welding of particles or, in some cases, transforming a crystalline material into an amorphous one.

How to Select the Right Ratio for Your Process

Use the standard ratio as your baseline, and adjust based on a clear understanding of your objective.

- If your primary focus is routine particle size reduction: Begin with the standard 10:1 BPR and a 50% jar filling. This is the most reliable starting point.

- If your primary focus is mechanical alloying or milling hard materials: Consider starting at 10:1 and cautiously increasing to 15:1 or 20:1, while carefully monitoring for increased contamination.

- If your priority is maintaining the absolute highest purity: Use a lower BPR, such as 5:1, and accept that the milling process will take significantly longer to complete.

- If you are using a large-scale industrial attritor: Disregard the 10:1 rule and follow the manufacturer's guidance, which will likely specify a much higher BPR (50:1 or more).

Ultimately, the ideal ratio is an experimental parameter you define to achieve your specific outcome with maximum efficiency.

Summary Table:

| Milling Goal | Recommended Starting BPR | Key Considerations |

|---|---|---|

| General Particle Size Reduction | 10:1 | Standard for lab-scale planetary/shaker mills. |

| Mechanical Alloying / Hard Materials | 15:1 - 20:1 | Higher energy impact; monitor for contamination. |

| High Purity Requirements | 5:1 | Slower process, minimizes contamination from wear. |

| Industrial Attritors | 50:1 - 100:1 | Follow manufacturer guidelines for large-scale mills. |

Achieve precise and efficient milling results with KINTEK.

Finding the perfect ball-to-powder ratio is crucial for your research, but it's only one part of the equation. The right lab equipment is just as important. KINTEK specializes in high-quality planetary ball mills, grinding jars, and milling media designed for consistent performance and minimal contamination.

Our experts can help you select the ideal setup for your specific application, whether you're focused on particle size reduction, mechanical alloying, or maintaining high purity. Let us partner with you to optimize your entire milling process.

Contact our technical team today for a personalized consultation and see how KINTEK's solutions can enhance your laboratory's capabilities.

Visual Guide

Related Products

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

People Also Ask

- Why is a Horizontal Planetary Ball Mill selected for grinding experiments? Simulate Industrial Stress for Graphite

- Why are ceramic balls preferred over steel balls for SiC/Aluminum mixing? Ensure Purity & Microstructure Integrity

- What size balls to use in a ball mill? A Guide to Optimizing Grinding Efficiency

- What particle size can be obtained through ball mill? From Microns to Nanometers with Precision Control

- What is the critical role of the planetary ball mill in the pretreatment of alloy powders like Cr40-Si60?

- What is the principle of planetary ball mill? Achieve Rapid, High-Energy Grinding for Your Materials

- Which mill is more effective than planetary ball mill for reducing particle size? Achieve Superior Nano-Grinding with Stirred Media Mills

- What role does a high-energy ball mill play in the synthesis of halide solid electrolytes like Li3YCl6 and Li3InCl6?