In ball mill operations, the critical speed is the theoretical rotational speed at which centrifugal force pins the grinding media against the inner wall of the mill. Its significance is not as a target to be reached, but as an essential benchmark. All effective grinding occurs at a calculated percentage of this critical speed, as reaching or exceeding it halts the milling process entirely.

Critical speed is not the goal; it is the fundamental constant against which the optimal operating speed is determined. The most efficient grinding does not happen at critical speed, but rather within a specific window—typically 65% to 80% of this value—where the tumbling and impact of the grinding media are maximized.

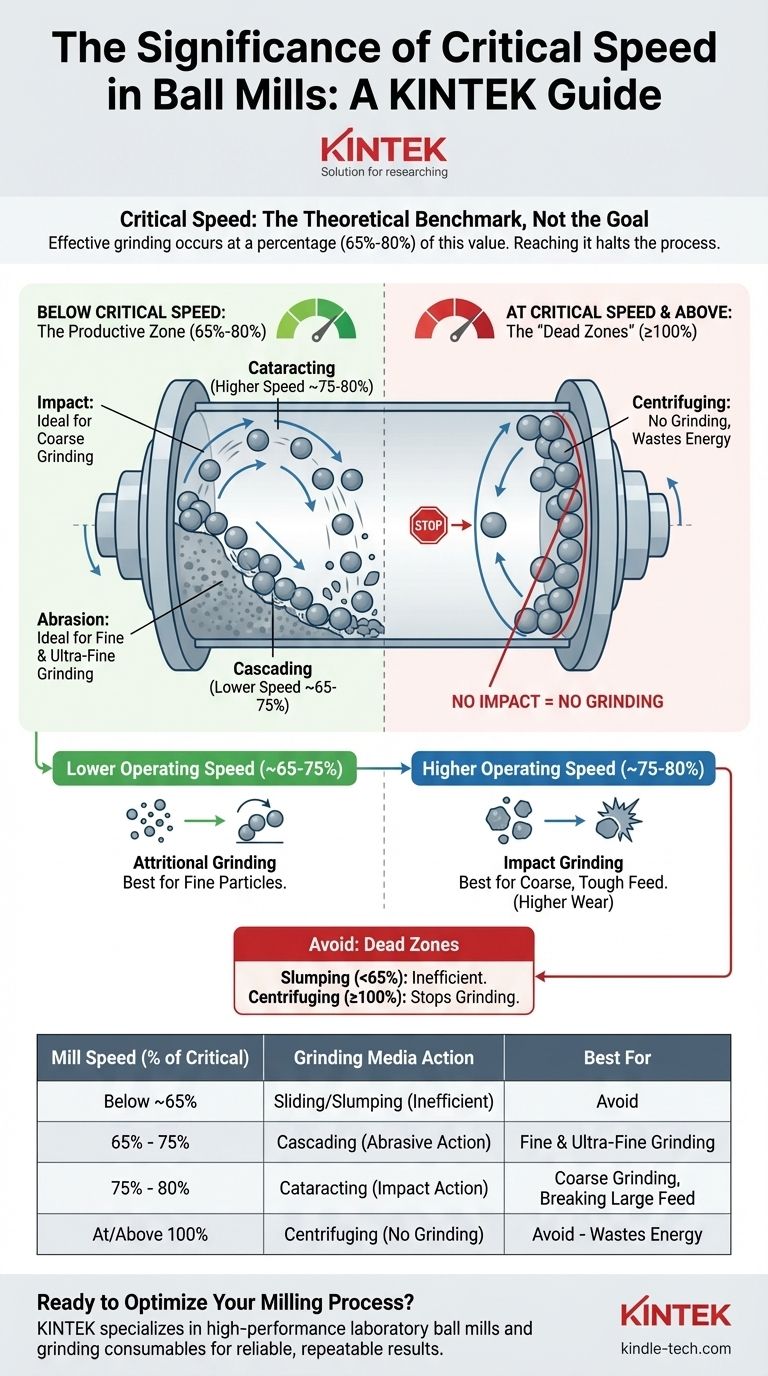

The Physics of Mill Speed: From Tumbling to Centrifuging

To grasp the importance of critical speed, you must first understand the different behaviors of the grinding media at various speeds. The entire process is a balance between the force of gravity, which pulls the media down, and the centrifugal force, which pushes it outwards.

Below Critical Speed: The Productive Zone

At speeds well below the critical value, the grinding media is lifted partway up the rotating wall of the mill and then tumbles back down. This tumbling action is what creates the impacts and abrasion needed to grind the material.

This productive zone includes two primary types of motion: cascading and cataracting. Cascading occurs at lower speeds, where media tumbles over itself, creating more abrasive grinding. Cataracting occurs at higher speeds, where media is thrown into the air, creating high-energy impacts.

At Critical Speed: The Point of No Return

As the mill's speed increases, so does the centrifugal force. The critical speed is the precise point where the outward centrifugal force perfectly balances and then overcomes the inward pull of gravity.

At this speed, the balls or rods stop tumbling and instead get "stuck" to the mill's inner lining, rotating with it in a fixed position. This is known as centrifuging. No tumbling means no impact, and therefore, no grinding can occur.

Above Critical Speed: Worsening Inefficiency

Operating above the critical speed does not re-initiate grinding. It only compounds the problem by ensuring the grinding media remains firmly pinned to the mill wall. This state is highly inefficient, wasting energy and producing no output.

Understanding the Trade-offs: The Grinding Action Spectrum

The reason critical speed is so significant is that it provides the reference point for dialing in your desired grinding action. Choosing a speed is a strategic decision based on your material and your desired final particle size.

Lower Operating Speeds (Cascading Motion)

Operating closer to 65% of critical speed causes the grinding media to tumble down the charge pile. This promotes attrition—a rubbing and shearing action.

This is ideal for fine or ultra-fine grinding, where the goal is to break down smaller particles through abrasion rather than forceful impact.

Higher Operating Speeds (Cataracting Motion)

Operating closer to 80% of critical speed causes the media to be thrown further into the mill, creating forceful impacts as they land on the material below. This promotes impact-based fracture.

This is ideal for coarse grinding, where the primary goal is to break down larger, tougher feed material quickly. However, this also causes higher wear on the mill liners and grinding media.

The "Dead Zones" to Avoid

There are two speeds that guarantee inefficiency. The first is a speed so low that the media merely slides or "slumps" at the bottom of the mill with minimal lifting.

The second, and more critical to understand, is any speed at or above 100% of the critical speed, where centrifuging stops all useful grinding action.

Setting Your Mill Speed for Optimal Performance

Use the critical speed calculation as the foundation for your operational strategy. Your choice of operating speed depends entirely on the outcome you wish to achieve.

- If your primary focus is coarse grinding or breaking large feed: Operate in the higher range (e.g., 75-80% of critical speed) to maximize impact forces through cataracting.

- If your primary focus is producing very fine particles: Operate in the lower range (e.g., 65-75% of critical speed) to emphasize abrasive grinding through a cascading motion.

- If your primary focus is efficiency and equipment longevity: Never operate at or above 100% of critical speed, and select the lowest possible speed within the productive zone that achieves your grinding target.

Ultimately, understanding critical speed transforms it from a theoretical limit into your most powerful tool for controlling and optimizing the grinding process.

Summary Table:

| Mill Speed (as % of Critical Speed) | Grinding Media Action | Best For |

|---|---|---|

| Below ~65% | Sliding/Slumping (Inefficient) | Avoid |

| 65% - 75% | Cascading (Abrasive Action) | Fine & Ultra-Fine Grinding |

| 75% - 80% | Cataracting (Impact Action) | Coarse Grinding, Breaking Large Feed |

| At/Above 100% | Centrifuging (No Grinding) | Avoid - Wastes Energy |

Ready to Optimize Your Milling Process?

Understanding critical speed is the first step to maximizing your lab's productivity and efficiency. The right equipment is essential for precise control.

KINTEK specializes in high-performance laboratory ball mills and grinding consumables, designed to give you the reliable, repeatable results you need. Whether your focus is on fine abrasion or coarse impact, we have the solutions to support your research and development.

Contact our experts today to discuss your specific application and find the perfect mill for achieving your particle size goals.

Visual Guide

Related Products

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Mini Planetary Ball Mill Machine for Laboratory Milling

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- Laboratory Horizontal Planetary Ball Mill Milling Machine

People Also Ask

- What is the function of a high-energy planetary ball mill in the synthesis of iodo-vanadate-lead ceramic waste forms?

- What is the function of a planetary ball mill in Al2O3-TiCN/Co-Ni composites? Achieve Perfect Material Homogenization

- What is the primary function of the ball milling process in SE-C electrode prep? Optimize Ion & Electron Transport

- What are the advantages of a ball mill? Achieve Superior Fine Grinding for Hard and Abrasive Materials

- How is a planetary ball mill used for modifying powders for extreme environments? Achieve Nano-Scale Material Precision

- What role does laboratory grinding equipment or planetary ball mills play in catalyst slurries? Precision Milling Guide

- How does a planetary mill work? Harnessing High-Energy Impact for Nano-Grinding

- What is the function of high-energy magnetic ball milling? Achieve Nanoscale Refinement in Fe-Al Powders