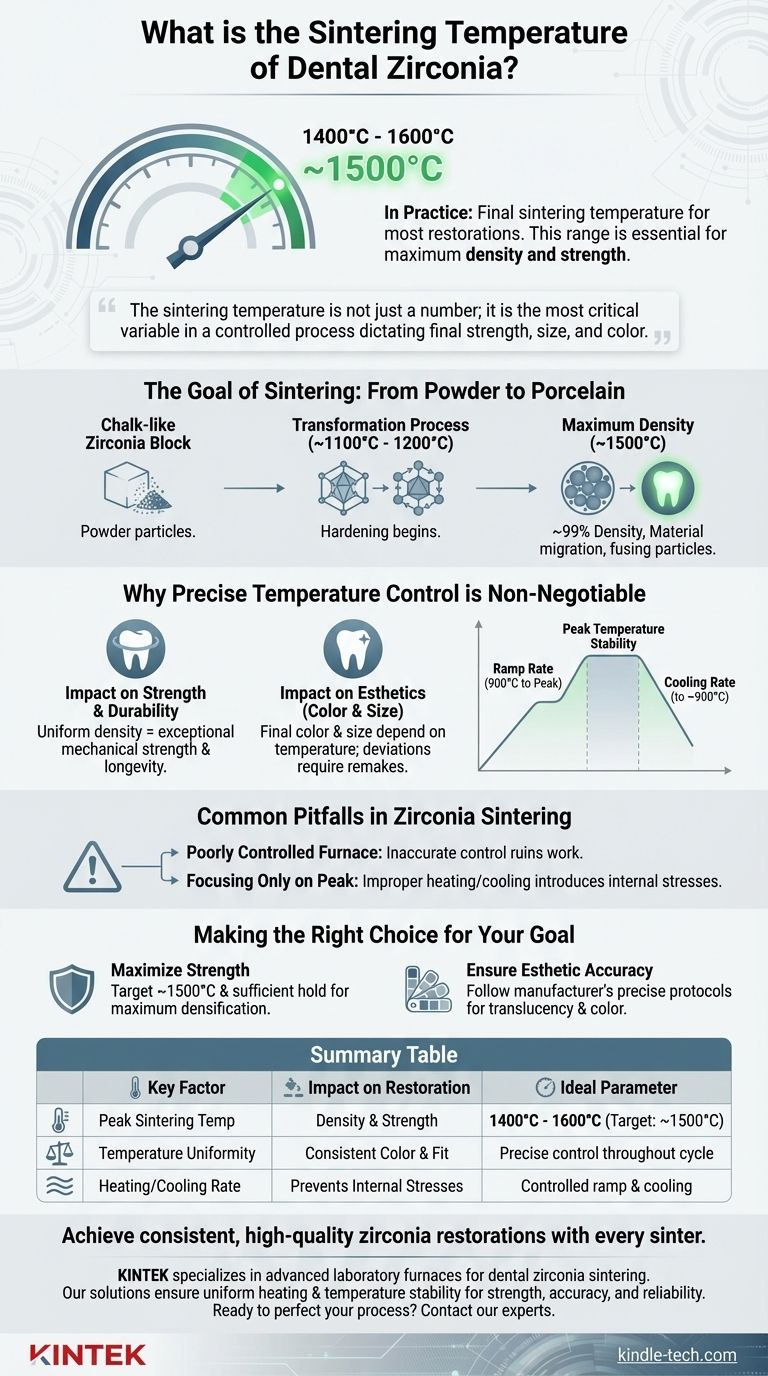

In practice, the final sintering temperature for most dental zirconia restorations is between 1400°C and 1600°C, with a common and effective target being around 1500°C. While the material begins to transform at a lower temperature, this higher range is required to achieve the maximum density and strength essential for clinical success.

The specific sintering temperature is not just a number to reach; it is the most critical variable in a controlled process that dictates the final strength, size, and color of the zirconia restoration. True quality comes from precisely managing the entire heating and cooling cycle, not just the peak temperature.

The Goal of Sintering: From Powder to Porcelain

Sintering is a thermal process that transforms a pre-shaped, chalk-like block of zirconia into a dense, high-strength ceramic restoration. It is a process of controlled densification.

The Transformation Process

At a foundational level, zirconia's crystalline structure changes from a monoclinic to a tetragonal state at approximately 1100°C to 1200°C. This is the beginning of its hardening process.

Achieving Maximum Density

To achieve the necessary clinical strength, the material must become as dense as possible. This requires higher temperatures where powder particles undergo material migration and fuse together, eliminating voids.

Firing at temperatures closer to 1500°C allows the zirconia to reach nearly 99% of its theoretical maximum density, which directly correlates to its final durability and resistance to fracture.

Why Precise Temperature Control is Non-Negotiable

The success or failure of a zirconia restoration is determined within the furnace. Inconsistent temperature control can easily ruin the significant workmanship invested in designing and milling the part.

Impact on Strength and Durability

Precise temperature regulation ensures the development of a uniformly dense structure. This density is what gives the final restoration its exceptional mechanical strength and longevity in the patient's mouth.

Impact on Esthetics (Color and Size)

The final color and size of a zirconia crown or veneer are directly related to the sintering temperature. Deviations can lead to restorations that don't match the shade guide or fit the preparation, requiring a complete remake.

The Critical Temperature Zones

The entire heating and cooling curve matters. However, the most critical phases are the ramp rate from 900°C to the peak temperature, the stability of the temperature during the hold time, and the cooling rate back down to around 900°C.

Common Pitfalls in Zirconia Sintering

Understanding what can go wrong highlights the importance of a meticulously controlled process. The primary point of failure is often the equipment and a lack of adherence to the full thermal cycle.

The Risk of a Poorly Controlled Furnace

A furnace with inaccurate or fluctuating temperature control is the biggest threat to quality. It can undo all the precise work of digital design and milling, resulting in a clinically useless restoration.

Focusing Only on Peak Temperature

Simply reaching 1500°C is not enough. An improper heating rate or a too-rapid cool-down can introduce internal stresses and micro-fractures, compromising the integrity of the final product even if it looks acceptable.

Making the Right Choice for Your Goal

Achieving consistent, high-quality results depends on aligning your sintering protocol with your primary objective for the restoration.

- If your primary focus is maximizing strength and durability: Target a peak temperature around 1500°C and ensure a sufficient hold time to achieve maximum densification, as recommended by the material manufacturer.

- If your primary focus is ensuring esthetic accuracy: Follow the zirconia manufacturer's specific temperature and time protocols with absolute precision, as even small deviations can affect translucency and color.

Mastering the sintering cycle is the final, critical step in transforming a zirconia blank into an exceptional dental restoration.

Summary Table:

| Key Factor | Impact on Restoration | Ideal Parameter |

|---|---|---|

| Peak Sintering Temperature | Determines final density & strength | 1400°C - 1600°C (Common target: ~1500°C) |

| Temperature Uniformity | Ensures consistent color & fit | Precise control throughout the cycle |

| Heating/Cooling Rate | Prevents internal stresses & fractures | Controlled ramp from 900°C to peak and back |

Achieve consistent, high-quality zirconia restorations with every sinter.

The precise thermal control of your furnace is the final, and most critical, step in your digital workflow. KINTEK specializes in advanced laboratory furnaces designed specifically for the demanding requirements of dental zirconia sintering.

Our solutions ensure the uniform heating and precise temperature stability you need to:

- Maximize Strength: Achieve near 99% density for durable, long-lasting restorations.

- Guarantee Accuracy: Maintain perfect shade matching and fit for every crown and bridge.

- Eliminate Remakes: Protect your investment in design and milling with reliable, repeatable results.

Ready to perfect your sintering process? Contact our dental lab experts today to find the ideal furnace for your laboratory's needs.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Vacuum Dental Porcelain Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is a burnout furnace? The Key to Flawless Precision Casting

- What is a dental porcelain furnace? The Key to In-House, High-Quality Dental Restorations

- What is the major drawback of all-ceramic restorations in the posterior of the mouth? Overcoming Fracture Risk for Long-Lasting Results

- What is sintering process in dentistry? Transform Milled 'Chalk' into Durable Dental Restorations

- At what temperature does zirconium oxide sinter? A Guide to Achieving Maximum Density and Strength

- What is a key consideration when purchasing a dental furnace? Ensure Material Compatibility for Superior Restorations

- What are some features found in many modern dental ovens? Enhancing Precision Through Digital Integration

- In what contexts is a slow cooling protocol important for dental restorations? Ensure Durability with Precise Thermal Care