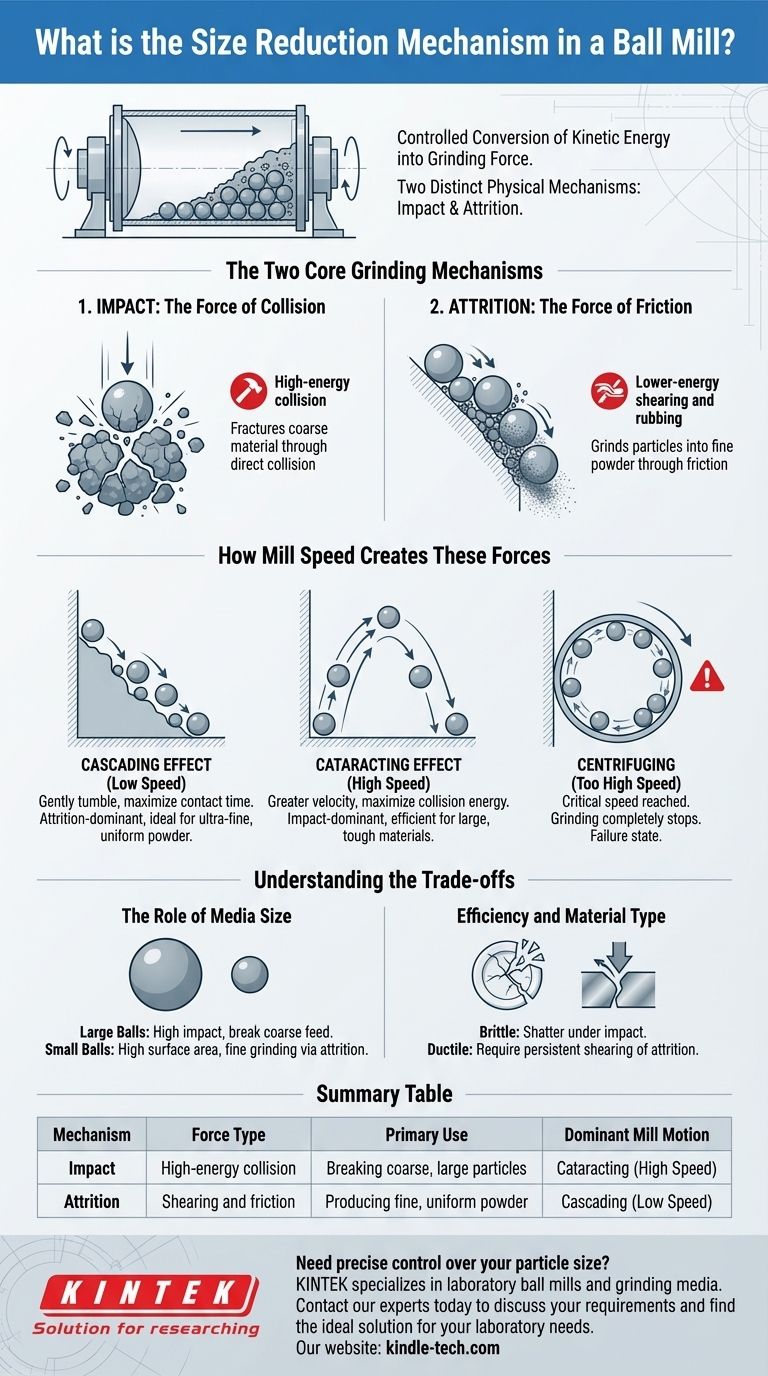

In a ball mill, size reduction is achieved through two distinct physical mechanisms. As the mill cylinder rotates, the grinding media (the balls) inside are lifted and then fall, converting the rotational energy into forces that break down the material. This process is a dynamic interplay between forceful collisions and grinding friction.

The core principle of a ball mill is the controlled conversion of kinetic energy into grinding force. This is accomplished through two primary actions: impact, which fractures coarse material through direct collision, and attrition, which grinds particles into a fine powder through friction and shear.

The Two Core Grinding Mechanisms

The effectiveness of a ball mill comes from its ability to apply two different types of force simultaneously. The balance between these forces is what determines the final particle size and the efficiency of the grinding process.

Impact: The Force of Collision

Impact is a high-energy event where a grinding ball falls and strikes the material. This is the primary mechanism for breaking down large, coarse feed particles.

As the mill's cylinder rotates, it lifts the balls up the side. At a certain height, gravity overcomes the forces holding the balls to the wall, and they detach, falling onto the material at the bottom of the mill. This action is like a hammer blow, causing brittle fracture in the target particles.

Attrition: The Force of Friction

Attrition is a lower-energy shearing and rubbing action. This mechanism is responsible for the fine grinding that reduces already small particles into a smooth powder.

This occurs when balls cascade and tumble over one another, trapping material between them. The resulting friction and shear forces rub the surfaces of the particles, gradually wearing them down and polishing them into a finer state.

How Mill Speed Creates These Forces

The rotational speed of the mill is the most critical operational parameter because it directly controls which grinding mechanism—impact or attrition—is dominant.

The Cascading Effect (Low Speed)

At lower speeds, the balls are not lifted very high up the cylinder wall. They gently tumble over each other in a continuous cascade down the face of the material.

This motion minimizes impact force but maximizes the contact time and rubbing action between the balls and the material. A cascading mill is attrition-dominant, ideal for producing an extremely fine, uniform powder.

The Cataracting Effect (High Speed)

As the rotational speed increases, centrifugal force carries the balls higher up the cylinder wall before they break free. They then follow a more parabolic path, falling with much greater velocity and force onto the material.

This cataracting motion maximizes collision energy, making the process impact-dominant. This is the most efficient way to quickly fracture larger, tougher materials.

Centrifuging (Too High Speed)

If the mill rotates too fast, it will reach a "critical speed." At this point, centrifugal force is so strong that it pins the grinding media and the material to the cylinder wall.

When this happens, there is no tumbling or falling, and therefore no relative motion. Grinding completely stops. This is a failure state that must be avoided.

Understanding the Trade-offs

Achieving the desired result requires balancing several key factors, not just the speed.

The Role of Media Size

The size of the grinding media is crucial. Large balls have more mass and generate significantly higher impact forces, making them effective for breaking down coarse feed.

Small balls, conversely, have a much higher total surface area and create more contact points. This makes them more effective at fine grinding through attrition and allows them to fill the void spaces between larger balls for a more uniform grind.

Efficiency and Material Type

The optimal balance of impact and attrition depends on the properties of the material being processed. Brittle materials like ceramics may shatter easily under impact, while more ductile materials may require the persistent shearing of attrition to be reduced effectively.

Matching the Mechanism to Your Goal

To operate a ball mill effectively, you must align its operating parameters with your desired outcome.

- If your primary focus is breaking down large, coarse particles: Run the mill at a higher speed to encourage a cataracting motion and use larger grinding media to maximize impact forces.

- If your primary focus is producing a very fine, uniform powder: Run the mill at a lower speed to create a cascading motion and use smaller grinding media to maximize attrition.

By mastering the interplay between speed, media, and material, you gain precise control over your final particle size.

Summary Table:

| Mechanism | Force Type | Primary Use | Dominant Mill Motion |

|---|---|---|---|

| Impact | High-energy collision | Breaking coarse, large particles | Cataracting (High Speed) |

| Attrition | Shearing and friction | Producing fine, uniform powder | Cascading (Low Speed) |

Need precise control over your particle size?

KINTEK specializes in laboratory ball mills and grinding media, helping you achieve the perfect balance between impact and attrition for your specific materials. Whether you need to crush coarse samples or create ultra-fine powders, our expertise ensures optimal efficiency and results for your lab.

Contact our experts today to discuss your grinding requirements and find the ideal solution for your laboratory needs.

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

People Also Ask

- Why use ball milling for NMC cathode materials? Achieve Precision Particle Sizing for Composite Cathodes

- What is the difference between a ball mill and a sag mill? A Guide to Primary vs. Secondary Grinding

- What is the key role of a planetary ball mill for IZO targets? Achieve Atomic-Level Uniformity in Material Preparation

- What is the purpose of ball milling? A Versatile Tool for Material Synthesis and Modification

- What is the product size of a ball mill? Achieve Micron-Level Precision for Your Materials