Sputtering is a highly controlled deposition process used to create exceptionally thin and uniform films. In a vacuum, a solid source material, known as the "target," is bombarded with high-energy ions from a gas plasma. This bombardment physically knocks atoms off the target, which then travel and deposit onto a component, called the "substrate," forming a precise coating.

Sputtering is fundamentally a process of momentum transfer, not evaporation. It uses the physical impact of ions to eject atoms from a source material, allowing for precise control over the resulting film's structure, density, and composition on a microscopic level.

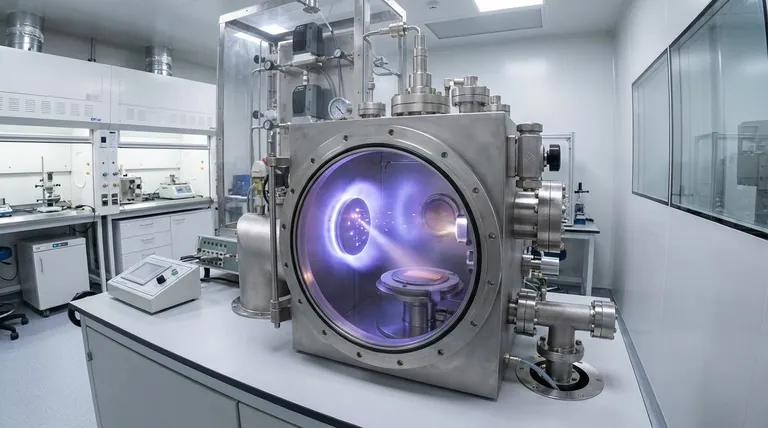

The Core Mechanism: From Plasma to Film

Sputtering is a physical vapor deposition (PVD) method that occurs in a series of well-defined steps inside a vacuum chamber.

Setting the Stage: The Vacuum Chamber

The process begins by placing the target (the source material for the film) and the substrate (the part to be coated) into a vacuum chamber. The chamber is evacuated to remove air and other contaminants that could interfere with the process.

Igniting the Plasma: The Role of Inert Gas

A small amount of an inert gas, most commonly Argon, is introduced into the chamber. A high voltage is applied, creating a negative charge on the target (making it the cathode) and a positive charge on the substrate or chamber walls (the anode).

This voltage energizes the gas, stripping electrons from the Argon atoms and creating a plasma—a glowing, ionized gas consisting of positive Argon ions and free electrons.

The Bombardment: Momentum Transfer in Action

The positively charged Argon ions are forcefully accelerated toward the negatively charged target. They strike the target's surface with significant kinetic energy.

This impact initiates collision cascades within the target's atomic structure. The energy is transferred from the ion to the target atoms, and if an atom near the surface receives enough momentum to overcome its atomic binding energy, it is ejected or "sputtered" from the target.

The Deposition: Coating the Substrate

The ejected atoms travel in a straight line through the vacuum chamber until they strike the substrate. Upon arrival, these atoms condense on the surface, nucleate, and grow into a thin, uniform film.

For precise control, a shutter is often placed between the target and substrate. This allows the sputtering process to stabilize before the shutter is opened to begin deposition.

Understanding the Trade-offs

While powerful, sputtering is not a universal solution. Understanding its limitations is key to using it effectively.

Lower Deposition Rates

Compared to thermal evaporation, sputtering can be a slower process. The rate of material transfer is limited by the efficiency of the ion bombardment, which can extend process times for thicker films.

Process Complexity and Heat

Sputtering systems are more complex and expensive than simple thermal evaporators. The constant ion bombardment also generates significant heat in the target, which often requires active cooling systems to prevent damage or changes in material properties.

Potential for Gas Incorporation

There is a small chance that ions from the sputtering gas (e.g., Argon) can become embedded in the growing film. This can alter the film's properties, such as its electrical resistivity or internal stress, which must be accounted for in sensitive applications.

Making the Right Choice for Your Goal

Selecting sputtering depends entirely on the required properties of the final film.

- If your primary focus is a dense, uniform film with high adhesion: Sputtering is an excellent choice, as the energetic atoms embed slightly into the substrate, creating a strong bond.

- If you need to deposit materials with high melting points or complex alloys: Sputtering is superior to thermal evaporation because it can deposit virtually any material without needing to melt it.

- If your primary focus is coating a simple material as quickly as possible: You might evaluate thermal evaporation, which can offer higher deposition rates for certain materials at a lower equipment cost.

By understanding sputtering as a physical process of controlled atomic transfer, you can leverage its precision to engineer films with highly specific characteristics.

Summary Table:

| Aspect | Description |

|---|---|

| Process Type | Physical Vapor Deposition (PVD) |

| Core Mechanism | Momentum transfer from ion bombardment |

| Key Advantage | Dense, uniform films with excellent adhesion |

| Ideal For | Materials with high melting points, alloys, complex compositions |

| Common Gas Used | Argon |

Need a precise, high-quality coating for your application? KINTEK specializes in advanced lab equipment, including sputtering systems, to help you achieve superior thin films with excellent uniformity and adhesion. Our experts are ready to assist you in selecting the right solution for your laboratory's specific materials and research goals. Contact our team today to discuss your project!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What role do porous substrates play in CDCVD beyond acting as a support? Master the Engine of Membrane Growth

- How is thin film formed? A Guide to PVD and CVD Deposition Methods

- Why are CVD or sintering furnaces necessary for SiC cladding? Unlock the Future of Accident Tolerant Fuel

- What are the components of MOCVD? A Detailed Breakdown of This Advanced Deposition System

- Why RF sputtering is better than DC sputtering? The Ultimate Guide to Material Deposition

- What is the chemical vapor deposition of silicon carbide? A Guide to High-Performance SiC Manufacturing

- What are the advantages of LPCVD? Achieve Superior Film Uniformity & High-Throughput Production

- What is metal CVD? A Guide to High-Precision Metal Coating for Electronics