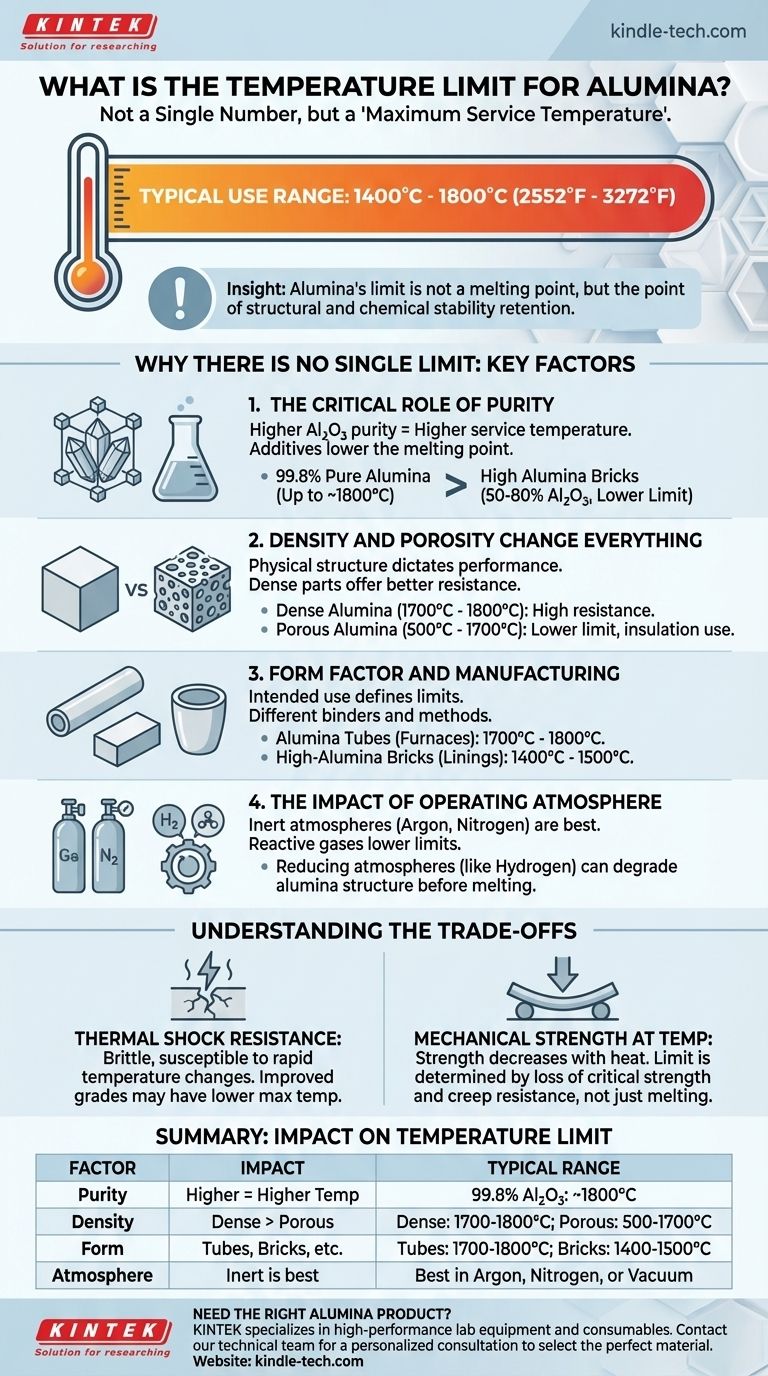

For practical applications, the maximum use temperature of alumina ceramic typically falls between 1400°C and 1800°C (2552°F to 3272°F). However, this is not a single, fixed number. The precise temperature limit is highly dependent on the alumina's purity, density, and the specific form of the final product.

The term "temperature limit" for alumina is misleading. Instead of a single melting point, you must consider the Maximum Service Temperature, which is the highest temperature at which the material retains its structural integrity and chemical stability for a specific application. This limit is determined by the product's purity, density, and operating environment.

Why There Is No Single Temperature Limit for Alumina

Alumina (Aluminum Oxide, Al₂O₃) is not one monolithic material but a category of ceramics. The manufacturing process and final composition dictate its performance under heat.

The Critical Role of Purity

The percentage of Al₂O₃ is the single most important factor. Additives and impurities, even in small amounts, can create lower-melting-point phases within the ceramic structure.

A higher purity level almost always corresponds to a higher maximum service temperature. For example, a 99.8% pure alumina component will have a significantly higher limit than a "high alumina brick" which may be only 50-80% alumina.

Density and Porosity Change Everything

The physical structure of the ceramic is just as important as its chemical makeup. A dense, fully sintered part behaves very differently from a porous one.

Dense alumina, with minimal voids, offers the highest temperature resistance, typically in the 1700°C to 1800°C range.

Porous alumina, designed for applications like insulation or filtration, has a much wider and generally lower service temperature range, from 500°C to 1700°C, because its structure is less robust.

Form Factor and Manufacturing

The final shape and intended use define the product's limits. Different binders and manufacturing methods are used for different forms.

Alumina tubes, often used in furnaces, are engineered for high density and thermal stability, commonly rated for 1700°C to 1800°C.

High-alumina bricks, used for furnace linings, are designed for a balance of insulation and structural strength, often placing their limit lower, around 1400°C to 1500°C.

The Impact of Operating Atmosphere

The maximum temperature is almost always specified for use in an inert atmosphere (like argon or nitrogen) or a vacuum.

Reactive atmospheres can significantly lower the effective temperature limit. For example, strong reducing atmospheres (like hydrogen) can begin to react with the alumina at high temperatures, degrading its structure long before it would melt.

Understanding the Trade-offs

Selecting an alumina product is not just about finding the highest temperature rating. You must consider the practical limitations and balances.

Thermal Shock Resistance

While excellent at handling sustained high heat, alumina can be brittle and susceptible to thermal shock. Rapid heating or cooling can cause it to crack.

Specialized grades are formulated to improve thermal shock resistance, but this may come at the cost of a slightly lower maximum service temperature.

Mechanical Strength at Temperature

A material's strength decreases as it gets hotter. The maximum service temperature is not its melting point (which is over 2000°C), but the point where it begins to lose a critical amount of its mechanical strength and resistance to creep (slow deformation under load).

Cost vs. Performance

There is a direct and steep correlation between performance and cost. A 99.8% pure, fully dense, custom-machined alumina component will be orders of magnitude more expensive than a standard high-alumina firebrick.

Making the Right Choice for Your Application

To select the correct material, you must match the product's specifications to your primary goal.

- If your primary focus is absolute maximum temperature resistance: You need a high-purity (99.5%+) and high-density (low porosity) alumina product, operated in an inert atmosphere.

- If your primary focus is furnace lining and insulation: High-alumina bricks or porous alumina plates offer the best balance of thermal insulation and structural integrity for their rated temperature.

- If your primary focus is for labware or process tubes: Standard dense alumina tubes offer excellent performance, but you must implement controlled heating and cooling cycles to avoid thermal shock.

Ultimately, understanding these key factors empowers you to look beyond a single number and choose the material truly suited to your needs.

Summary Table:

| Factor | Impact on Temperature Limit | Typical Range |

|---|---|---|

| Purity | Higher purity = higher temperature resistance | 99.8% Al₂O₃: ~1800°C |

| Density | Dense parts resist heat better than porous ones | Dense: 1700-1800°C; Porous: 500-1700°C |

| Form/Product | Tubes, bricks, and labware have different ratings | Tubes: 1700-1800°C; Bricks: 1400-1500°C |

| Atmosphere | Inert atmospheres preserve integrity; reactive gases lower the limit | Best in argon, nitrogen, or vacuum |

Need the right alumina product for your high-temperature application?

At KINTEK, we specialize in high-performance lab equipment and consumables. Our experts understand that the 'right' alumina depends on your specific needs—whether it's for maximum temperature resistance, thermal insulation, or resistance to thermal shock. We provide high-purity, dense alumina tubes, bricks, and custom components designed for reliability in demanding laboratory environments.

Let us help you select the perfect material to ensure your process runs safely and efficiently. Contact our technical team today for a personalized consultation!

Visual Guide

Related Products

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- Electrode Polishing Material for Electrochemical Experiments

- Conductive Carbon Cloth Carbon Paper Carbon Felt for Electrodes and Batteries

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

- Rubber Vulcanizer Vulcanizing Machine Plate Vulcanizing Press for Lab

People Also Ask

- What is the purpose of using high-hardness zirconia grinding balls? Ensure Purity & Power in Electrolyte Milling

- Why are zirconia grinding balls recommended for sulfide solid electrolytes? Essential Tips for High Purity Milling

- Why are zirconia grinding balls preferred for NiCrAlY-Mo-Ag powders? Ensure Maximum Purity and Durability

- Why are ZrO2 grinding jars and balls required for sulfide solid electrolytes? Ensure Purity & Performance

- What are the advantages of using zirconia milling jars for sulfide electrolytes? Enhance Purity and Conductivity