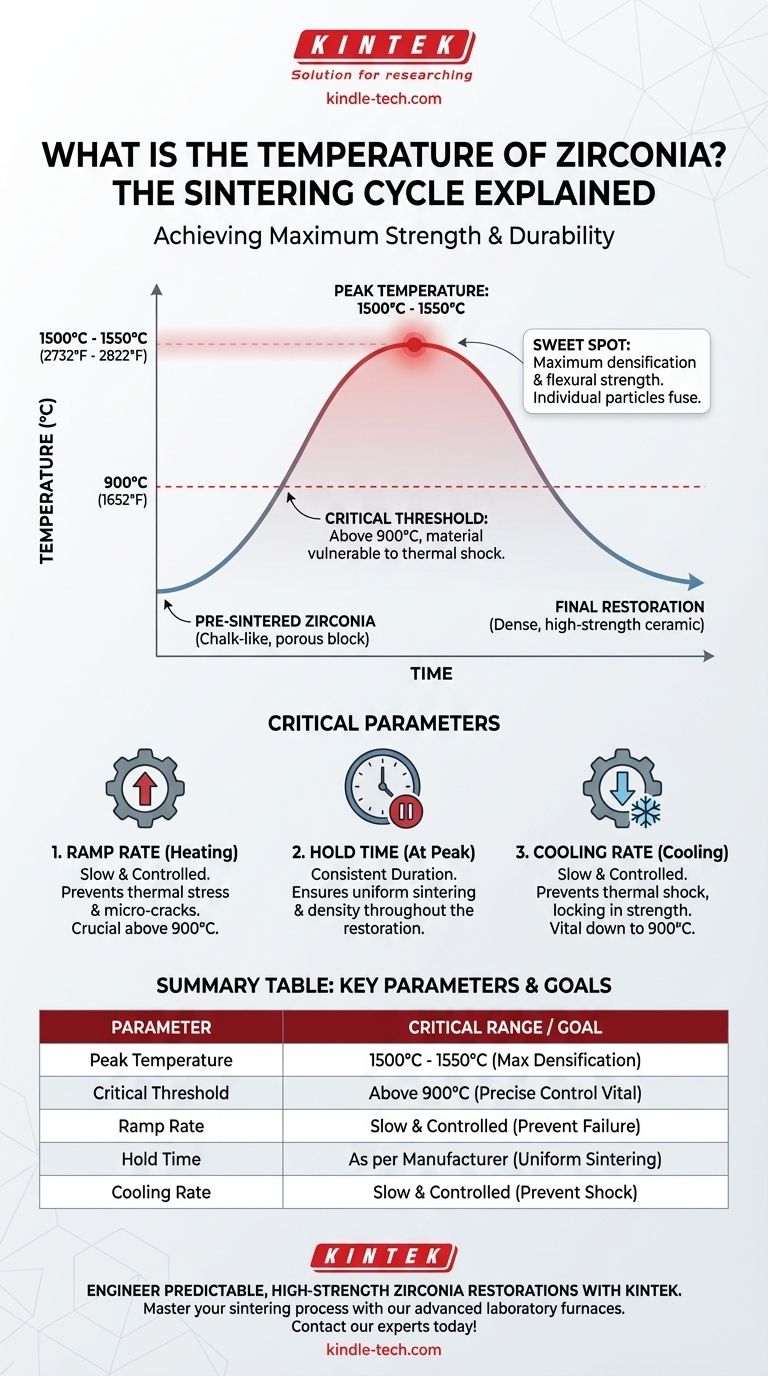

The optimal firing temperature for achieving maximum strength in most dental zirconia restorations is between 1500°C and 1550°C (2732°F - 2822°F). However, hitting this peak temperature is only one part of a much more critical thermal process that dictates the final quality and durability of the material.

Achieving a successful zirconia restoration is less about a single temperature and more about precisely controlling the entire sintering cycle. The critical phases of heating and cooling, particularly above 900°C, are what truly determine the final strength and stability of the material.

Why Sintering Is a Process, Not a Number

To understand the temperature of zirconia, you must understand the goal of sintering. This process transforms a chalk-like, pre-sintered zirconia block into a dense, high-strength ceramic restoration.

The Goal of Sintering

Sintering works by heating the material to a point where its individual particles begin to fuse, eliminating the porous spaces between them. This densification is what gives the final restoration its immense strength and desired translucency.

Reaching Peak Temperature (1500°C - 1550°C)

This specific temperature range represents the "sweet spot" for most zirconia formulations. It is at this peak that the material achieves maximum densification and, therefore, maximum flexural strength. Firing below this range can result in an under-sintered, weaker restoration.

The Critical 900°C Threshold

The temperature profile below 900°C (1652°F) has a minimal effect on the zirconia. The critical phase change that makes the material vulnerable to thermal shock occurs above this point.

Therefore, the entire process—from 900°C up to the peak temperature and back down to 900°C—must be precisely managed.

Understanding the Trade-offs and Critical Parameters

Simply setting the oven to 1550°C is not enough. The rates of heating and cooling are arguably more important than the peak temperature itself for preventing failures.

The Impact of Ramp Rate

The ramp rate is the speed at which the furnace temperature increases. A rapid ramp rate, especially after 900°C, can introduce thermal stresses into the material, leading to micro-cracks or even catastrophic failure. A slow, controlled ramp is essential for thermal stability.

The Importance of Hold Time

Once the peak temperature is reached, it must be held consistently for a specified duration, known as the hold time. This allows the sintering process to complete evenly throughout the entire restoration, ensuring uniform density and strength.

Cooling: The Critical Final Step

Controlled cooling is just as important as controlled heating. The restoration must be cooled slowly and steadily back to below 900°C. Rapid cooling will cause thermal shock, compromising the integrity and strength gained during the hold time.

How to Apply This to Your Process

Your approach should be guided by the manufacturer's instructions for the specific zirconia material you are using, as different formulations can have slightly different ideal cycles.

- If your primary focus is maximum strength: Adhere strictly to the recommended peak temperature, typically between 1500°C and 1550°C, and ensure your furnace is properly calibrated.

- If your primary focus is preventing fractures and ensuring stability: Pay closest attention to the heating and cooling rates, especially within the critical window between 900°C and the peak sintering temperature.

By mastering the entire thermal cycle, you move from simply firing zirconia to engineering a predictable and durable final restoration.

Summary Table:

| Parameter | Critical Range / Goal | Why It Matters |

|---|---|---|

| Peak Temperature | 1500°C - 1550°C (2732°F - 2822°F) | Achieves maximum densification and strength. |

| Critical Threshold | Above 900°C (1652°F) | Material is vulnerable to thermal shock; precise control is vital. |

| Ramp Rate | Slow and Controlled | Prevents thermal stress, micro-cracks, and catastrophic failure. |

| Hold Time | As per manufacturer | Ensures uniform sintering and consistent density throughout the restoration. |

| Cooling Rate | Slow and Controlled | Prevents thermal shock, locking in the strength gained during sintering. |

Engineer predictable, high-strength zirconia restorations with a KINTEK dental furnace.

Achieving the perfect sintering cycle requires precise control over temperature, ramp rates, and cooling. KINTEK's advanced laboratory furnaces are engineered to deliver the repeatable accuracy your dental lab needs for flawless results batch after batch.

We specialize in providing reliable lab equipment to dental technicians focused on quality and efficiency. Let us help you master your sintering process.

Contact our experts today to find the ideal furnace for your zirconia workflow!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is one of the newest applications for dental ceramics? Monolithic Zirconia for Full-Arch Bridges

- What are the white spots on zirconia after sintering? A Guide to Diagnosing and Preventing Defects

- Can you change the color of zirconia crowns? Understanding the Permanent Nature of Zirconia

- What is the sintering temperature of zirconium? A Guide to the 1400°C-1600°C Range for Dental Labs

- What makes zirconia translucent? The Science Behind Modern Dental Aesthetics