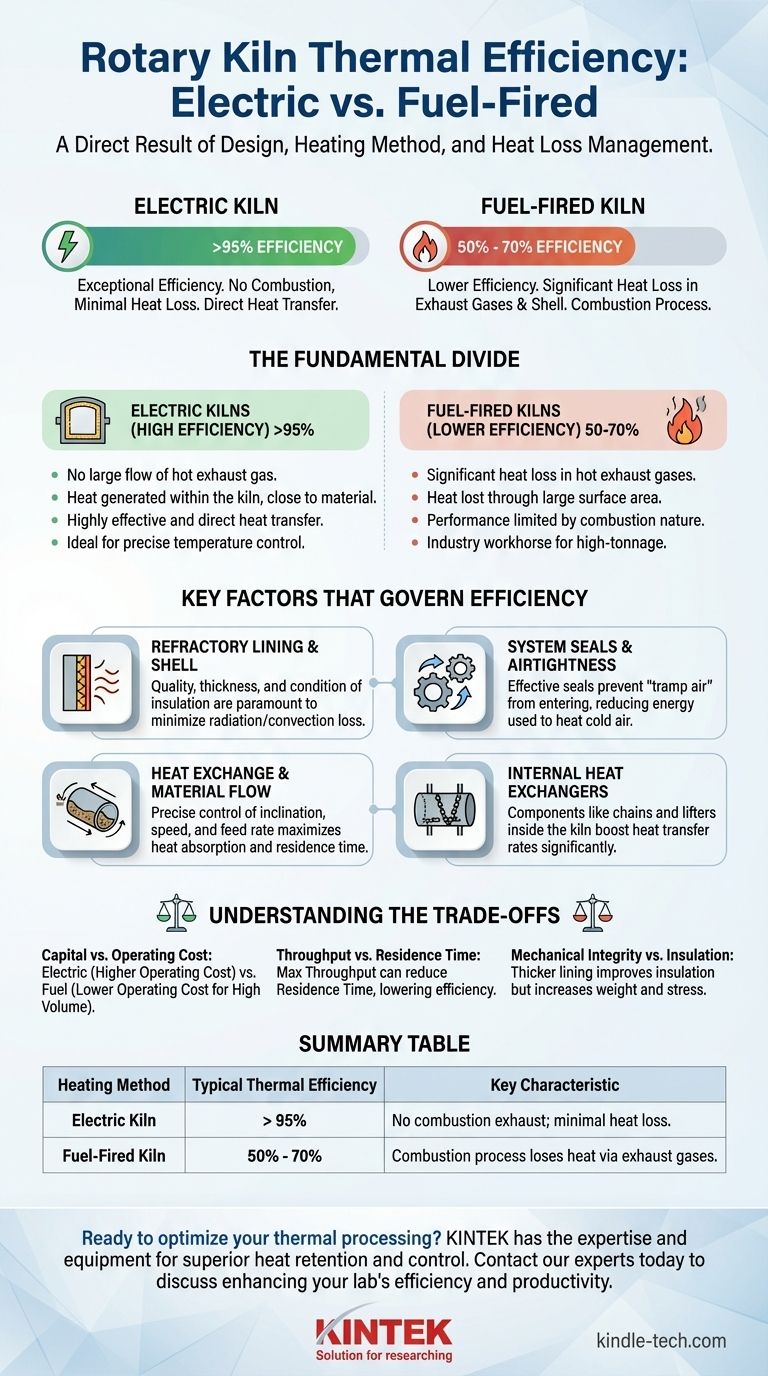

The thermal efficiency of a rotary kiln depends entirely on its heating method. While a modern, electrically heated kiln can achieve an energy efficiency of over 95% due to minimal heat loss, the more common fuel-fired kilns have significantly lower efficiencies, typically ranging from 50% to 70%, primarily due to heat lost in exhaust gases.

A kiln's efficiency is not a single, fixed value. It is the direct result of its fundamental design—specifically, how it generates heat (electric vs. fuel) and how effectively it minimizes heat loss through its shell, seals, and exhaust.

The Fundamental Divide: Electric vs. Fuel-Fired Kilns

The single largest factor determining a rotary kiln's potential efficiency is its heat source. This choice creates two distinct classes of equipment with vastly different performance profiles.

The High Efficiency of Electric Kilns

An electrically heated rotary kiln functions with exceptional efficiency, often exceeding 95%. This is achieved because there is no fuel combustion.

Without combustion, there is no large flow of hot exhaust gas required to carry heat, which is the primary source of energy loss in traditional kilns. The heat is generated within the kiln, close to the material, resulting in highly effective and direct heat transfer.

The Reality of Fuel-Fired Kilns

Fuel-fired kilns are the industry workhorse for high-tonnage production, but they operate at a lower thermal efficiency. Their performance is fundamentally limited by the nature of combustion.

A significant portion of the heat generated by burning fuel is immediately lost as it is carried out of the system by hot exhaust gases. Additional heat is constantly lost to the environment through the kiln's large surface area.

Key Factors That Govern Kiln Efficiency

Regardless of the type, a kiln's efficiency is a battle against heat loss. Several critical components and operational parameters determine how well that battle is fought.

The Refractory Lining and Shell

The kiln's shell is lined with a refractory material that acts as insulation. The quality, thickness, and condition of this lining are paramount. A degraded or poorly designed lining allows more heat to escape through the steel shell via radiation and convection.

System Seals and Airtightness

A rotary kiln must have effective seals at the feed inlet and product discharge ends. Poor sealing allows uncontrolled "tramp air" to be drawn into the kiln. This cold air must then be heated, consuming a massive amount of energy that does not go into processing the material.

Heat Exchange and Material Flow

A rotary kiln is fundamentally a heat exchanger. Its inclination angle, rotation speed, and material feed rate must be precisely controlled. The goal is to maximize the material's residence time and exposure to heat, ensuring the heat is absorbed by the product rather than escaping out the back end.

Internal Heat Exchangers

Components like chains or lifters can be installed inside the kiln. These internals pick up heat from the hot gas stream and shower it down onto the material bed, dramatically improving the rate of heat transfer and boosting overall efficiency.

Understanding the Trade-offs

Pursuing maximum efficiency always involves balancing competing priorities. Understanding these trade-offs is key to making sound engineering and operational decisions.

Capital Cost vs. Operating Cost

Electric kilns boast superior efficiency, but the per-unit cost of electricity is often much higher than that of natural gas or coal. Therefore, a fuel-fired kiln may have a lower total operating cost despite its lower thermal efficiency, especially in high-volume applications.

Throughput vs. Residence Time

Increasing the material feed rate to maximize production (throughput) can be counterproductive. It reduces the time the material spends in the kiln, which can lead to incomplete processing and poor heat transfer, ultimately lowering thermal efficiency.

Mechanical Integrity vs. Insulation

While a thicker refractory lining provides better insulation, it also adds weight and can be more susceptible to mechanical stress and spalling. The design must balance the need for heat retention with the long-term structural integrity of the kiln shell and lining.

Making the Right Choice for Your Goal

To optimize performance, you must align the kiln's design and operation with your primary objective.

- If your primary focus is maximum thermal efficiency and precise temperature control: An electrically heated kiln is the definitive choice, capable of exceeding 95% efficiency.

- If your primary focus is processing large volumes with lower-cost fuel: A fuel-fired kiln is the practical solution, but you must prioritize high-quality seals, insulation, and internal heat exchangers to maximize its performance.

- If your primary focus is improving an existing kiln: The highest-impact upgrades will be ensuring the inlet and outlet seals are perfectly airtight and evaluating the condition of the refractory lining.

Ultimately, a rotary kiln's efficiency is not a static number but a direct result of deliberate design choices and meticulous operational control.

Summary Table:

| Heating Method | Typical Thermal Efficiency | Key Characteristic |

|---|---|---|

| Electric Kiln | > 95% | No combustion exhaust; minimal heat loss. |

| Fuel-Fired Kiln | 50% - 70% | Combustion process loses heat via exhaust gases. |

Ready to optimize your thermal processing?

Whether your priority is maximum energy efficiency with an electric kiln or high-volume processing with a fuel-fired system, KINTEK has the expertise and equipment to meet your laboratory's specific needs. Our rotary kilns are engineered for superior heat retention and control.

Contact our experts today to discuss how we can enhance your lab's efficiency and productivity.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the types of pyrolysis reactors used in industry? Choose the Right Technology for Your Product

- What are the products of pyrolysis of wood? A Guide to Biochar, Bio-oil, and Syngas Yields

- What is the difference between calcining and roasting? A Guide to High-Temperature Processing

- What are the zones in rotary kiln in cement production? Master the Core Process for High-Quality Clinker

- What are the industrial applications of pyrolysis? Transform Waste into Energy and Valuable Products