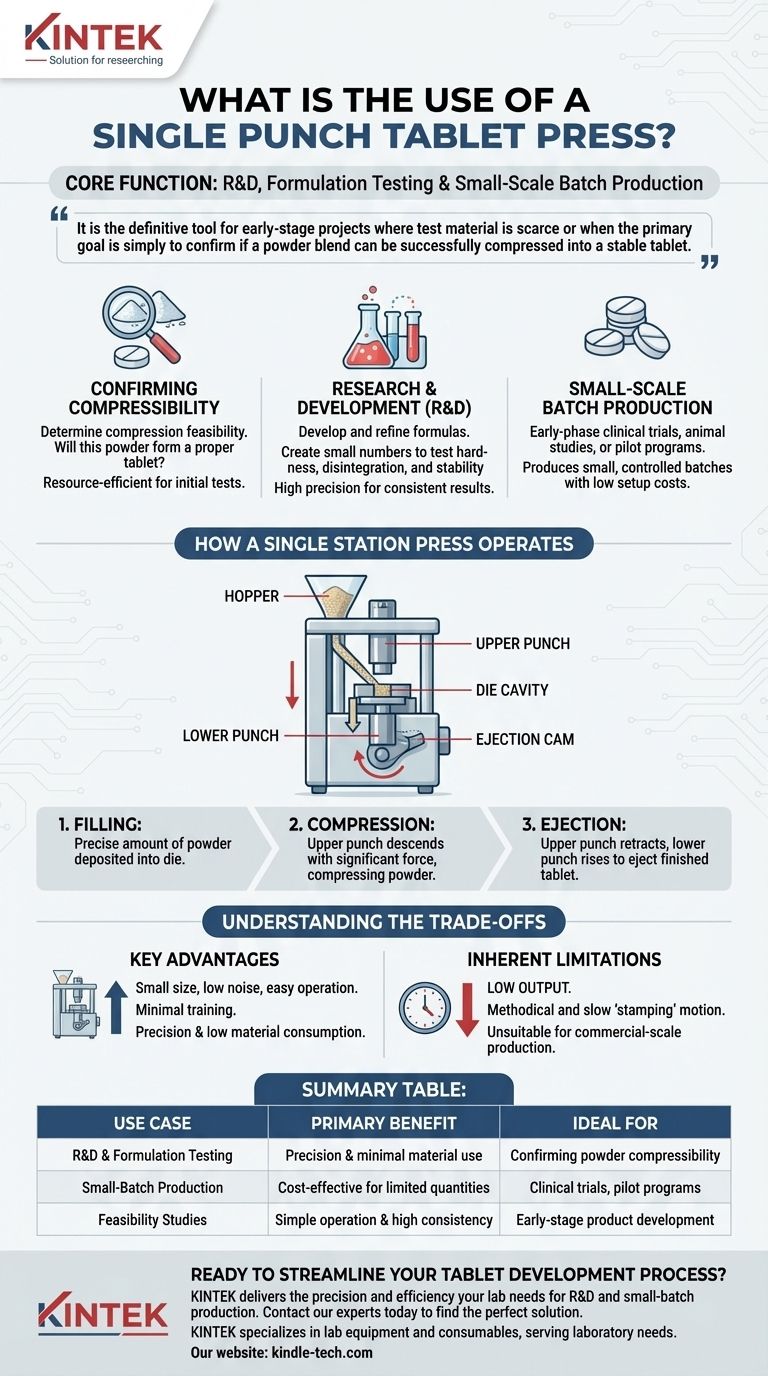

At its core, a single punch tablet press is used for compressing powdered materials into tablets, specifically for research and development (R&D), formulation testing, and small-scale batch production. It is the definitive tool for early-stage projects where test material is scarce or when the primary goal is simply to confirm if a powder blend can be successfully compressed into a stable tablet.

A single punch press is not designed for mass production. Its value lies in its precision, simplicity, and efficiency with small quantities of material, making it an indispensable tool for feasibility studies and laboratory-scale development.

The Primary Role: From Powder to Prototype

A single punch press, also known as a single station or eccentric press, serves a critical function at the beginning of the product development lifecycle. Its use cases are highly specific and distinct from large-scale manufacturing equipment.

Confirming Compressibility

The most fundamental use is to determine the compression feasibility of a new powder formulation. Before investing in expensive materials and large equipment, researchers use a single punch press to answer the basic question: "Will this powder form a proper tablet?"

Because it uses very little material per cycle, it is the most resource-efficient way to conduct these initial tests.

Research and Development (R&D)

In a laboratory setting, a single punch press is essential for developing and refining tablet formulas. It allows scientists to create small numbers of tablets to test characteristics like hardness, disintegration time, and stability.

Its simple operation and high precision in filling allow for consistent results, which are crucial for comparing different formulations.

Small-Scale Batch Production

For needs like producing tablets for early-phase clinical trials, animal studies, or pilot programs, the single punch press is a perfect fit. It can produce small, controlled batches without the complexity and high setup costs of a large manufacturing line.

How a Single Station Press Operates

The machine's design is straightforward, centering on a single set of tooling that performs the entire compression cycle. This mechanism is often described as a stamping or hammer-like motion.

The Core Components

A single punch press works using a single station of tooling, which consists of an upper punch, a lower punch, and a die.

The powder is held in a hopper and fed into the die cavity. The punches then compress the powder within the die to form the tablet. Finally, an ejection cam removes the finished tablet.

The Step-by-Step Process

The operation is a continuous, automated cycle:

- Filling: A precise amount of powder is moved from the hopper and deposited into the die cavity.

- Compression: The upper punch descends with significant force, compressing the powder between it and the stationary lower punch.

- Ejection: The upper punch retracts, and the lower punch rises to eject the finished tablet from the die, making it ready for the next cycle.

Understanding the Trade-offs

While invaluable in its niche, the single punch press has clear advantages and limitations that define its proper use.

Key Advantages

The main benefits are its small size, low noise, and ease of operation. It requires minimal training and can fit easily within a laboratory environment.

Its precision and low material consumption make it the ideal choice when working with expensive or limited active ingredients.

Inherent Limitations

The primary trade-off is low output. The "stamping" motion of a single station press is methodical and relatively slow. It is completely unsuitable for commercial-scale production, where tens of thousands of tablets per hour are required.

Its purpose is not speed but precision and efficiency on a small scale. For high volume, a multi-station rotary tablet press is necessary.

Making the Right Choice for Your Goal

Selecting the correct equipment depends entirely on your project's objective.

- If your primary focus is early-stage R&D or feasibility testing: A single punch press is the perfect choice due to its precision and minimal material consumption.

- If your primary focus is small-batch production for clinical trials: This machine offers a cost-effective and simple solution for producing the limited quantities you need.

- If your primary focus is large-scale commercial manufacturing: You must look beyond a single punch press to a multi-station rotary press designed for high output.

Ultimately, the single punch press excels by providing a precise, reliable, and material-efficient path from powder formulation to a viable tablet prototype.

Summary Table:

| Use Case | Primary Benefit | Ideal For |

|---|---|---|

| R&D & Formulation Testing | Precision & minimal material use | Confirming powder compressibility |

| Small-Batch Production | Cost-effective for limited quantities | Clinical trials, pilot programs |

| Feasibility Studies | Simple operation & high consistency | Early-stage product development |

Ready to streamline your tablet development process? A KINTEK single punch tablet press delivers the precision and efficiency your lab needs for R&D and small-batch production. Whether you're testing new formulations or producing tablets for clinical trials, our equipment ensures reliable results with minimal material waste. Contact our experts today to find the perfect solution for your laboratory needs. KINTEK specializes in lab equipment and consumables, serving laboratory needs.

Visual Guide

Related Products

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Multi-Punch Rotary Tablet Press Mold Ring for Rotating Oval and Square Molds

- Automatic Laboratory Heat Press Machine

People Also Ask

- What is the pressed pellet technique? A Guide to Creating Uniform Solid Samples from Powder

- What are the different parts of a single punch tablet machine? The Core Components Explained

- What is tablet pressing in pharmaceutical industry? The Core Process for Producing Solid Oral Dosage Forms

- What are the advantages of press working operation? Unlock High-Speed, Low-Cost Mass Production

- What is a punch tablet press? Precision Tableting for R&D and Small Batches