At its core, a tablet press is a machine that transforms powder into solid tablets. Its primary function is to compress various powdered or granular materials into tablets of a uniform size, shape, and hardness through the application of immense force. This process is fundamental in the pharmaceutical, nutraceutical, and chemical industries.

The central purpose of a tablet press is to ensure dose uniformity and stability by converting powders into a solid, manageable form. It achieves this by precisely controlling the compression process within a die using specialized punches.

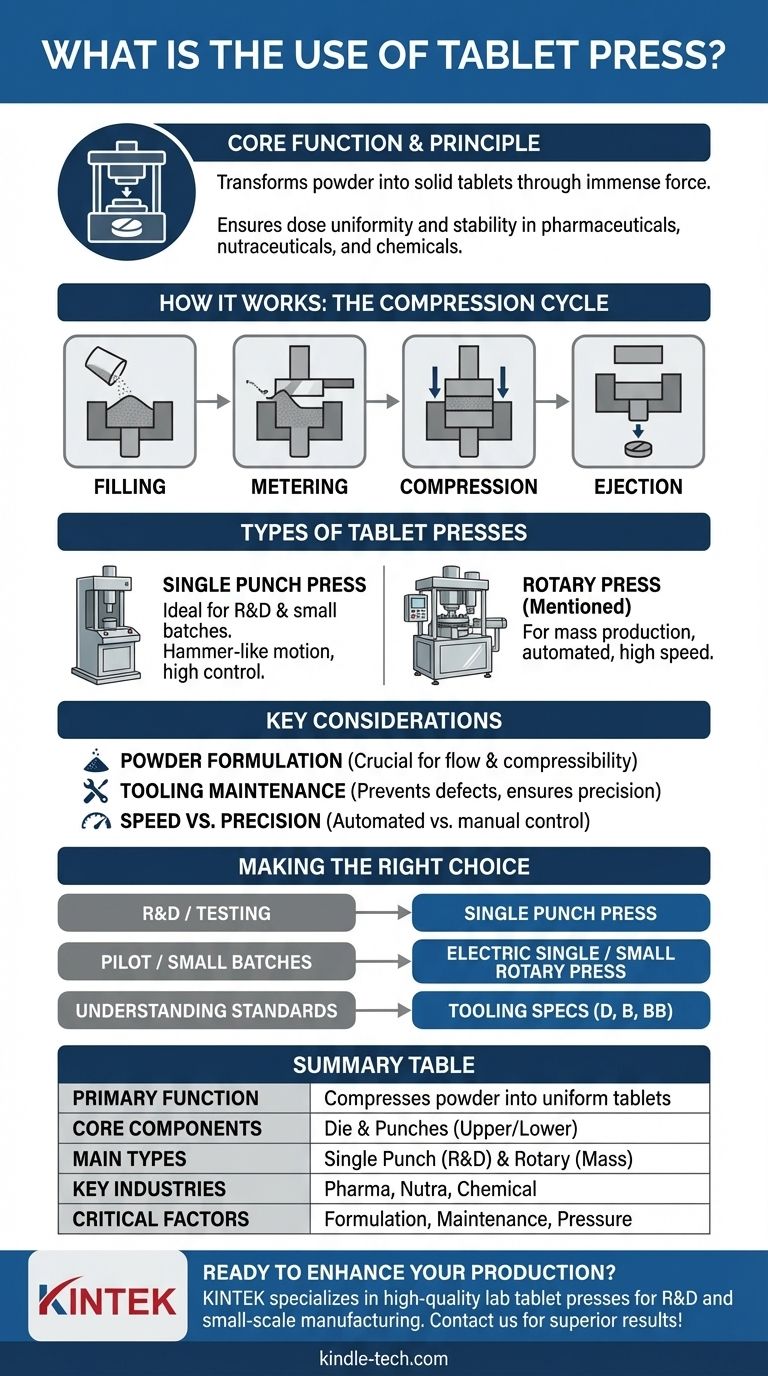

The Core Principle: How a Tablet Press Works

Understanding how a tablet press functions requires looking at its essential components and the cyclical process they perform. The entire operation is based on the simple principle of compression.

The Key Components: Punches and a Die

The heart of any tablet press is the tooling station, which consists of three parts: a die and a pair of punches (upper and lower).

The die is a precision-machined cavity that defines the shape and diameter of the final tablet. The punches are steel tools that move within the die to compress the powder.

The Compression Cycle Explained

The tableting process is a continuous, multi-stage cycle.

- Filling: The lower punch is lowered within the die, creating a cavity that is then overfilled with the powdered formulation.

- Metering: The excess powder is scraped off the surface of the die, ensuring a precise and consistent volume of material for each tablet.

- Compression: The upper punch descends into the die, and both punches move together, applying extremely high force to compact the powder into a solid form.

- Ejection: The upper punch retracts, and the lower punch rises to push the finished tablet out of the die.

The Role of Pressure

A hydraulic or mechanical pressure mechanism applies the force required for compression. Operators can adjust the pressure to control the hardness and tightness of the resulting tablet, ensuring it meets specific requirements for durability and dissolution.

Types of Tablet Presses

While the core principle remains the same, tablet presses vary in their mechanics and intended use, primarily differing in automation and scale.

Single Punch (Eccentric) Press

A single punch press, also known as a single station press, utilizes a single tooling station with an upper punch, a lower punch, and a die.

In this design, the upper punch performs a hammer-like motion to exert the compression force, while the lower punch is primarily involved in filling and ejection. These machines are relatively simple and are the go-to choice for specific applications.

Manual vs. Electric Presses

The primary difference lies in the source of power and level of control.

A manual press requires the operator to physically control the compression process. These often include pressure gauges to help the operator monitor and adjust the force being applied.

An electric press uses a motor to automate the compression cycle. The operator sets parameters like pressure and speed, and the machine executes the process repeatedly and consistently.

Common Pitfalls and Considerations

While effective, the tableting process has critical variables that must be managed to ensure quality and avoid common issues.

Powder Formulation is Critical

The success of tableting is highly dependent on the properties of the powder. Poor flowability can lead to inconsistent die filling and tablet weight, while poor compressibility will result in weak or crumbling tablets.

Tooling Maintenance

The punches and dies are high-precision components that are subject to immense force and abrasive wear. Proper maintenance, cleaning, and storage are essential to prevent tablet defects like sticking, picking, or capping (where the top of the tablet separates).

Speed vs. Precision

Automated, high-speed rotary presses (not detailed in the references but a key industry machine) prioritize output for mass production. In contrast, simpler single punch presses offer greater control and are better suited for the meticulous work of formulation development and small-scale testing.

Making the Right Choice for Your Goal

Selecting the right type of tablet press depends entirely on your specific objective.

- If your primary focus is Research & Development (R&D): A single punch press (either manual or electric) is ideal for testing new formulations and producing small, experimental batches.

- If your primary focus is Pilot Production or Small Batches: An electric single punch or a small rotary press allows for consistent production on a limited scale before scaling up.

- If your primary focus is understanding tablet standards: Familiarize yourself with tooling specifications like 'D', 'B', and 'BB', which are standardized sizes used in lab and production environments to ensure process scalability.

Ultimately, the tablet press is an indispensable tool for converting raw materials into a precise, effective, and marketable final product.

Summary Table:

| Aspect | Key Information |

|---|---|

| Primary Function | Compresses powder into uniform tablets of specific size, shape, and hardness. |

| Core Components | Die (defines shape) and Punches (upper and lower for compression). |

| Main Types | Single Punch Press (for R&D/small batches) and Rotary Press (for mass production). |

| Key Industries | Pharmaceutical, Nutraceutical, Chemical. |

| Critical Factors | Powder formulation, tooling maintenance, and pressure control. |

Ready to enhance your tablet production with precision and reliability? At KINTEK, we specialize in high-quality lab equipment, including tablet presses designed for R&D, pilot production, and small-scale manufacturing. Whether you're developing new formulations or need consistent small-batch output, our solutions ensure dose uniformity, stability, and efficiency.

Contact us today to find the perfect tablet press for your laboratory needs and achieve superior results in your tableting process!

Visual Guide

Related Products

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

- Multi-Punch Rotary Tablet Press Mold Ring for Rotating Oval and Square Molds

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

People Also Ask

- What are the different parts of a single punch tablet machine? The Core Components Explained

- What is tablet pressing in pharmaceutical industry? The Core Process for Producing Solid Oral Dosage Forms

- What is the purpose of the pelletizing machine? Transform Waste into Valuable, Dense Pellets

- What is the difference between a rotary tablet press and a single tablet punch press? A Guide to Choosing the Right Machine

- What does a tablet punching machine consist of? Core Components for Efficient Tablet Production

- What are pill presses used for? Transforming Powders into Precise Tablets for Medicine, Supplements, and More

- What is a punch tablet press? Precision Tableting for R&D and Small Batches

- Which type of tablet press is more suitable for large scale production? Rotary Presses for High-Volume Efficiency