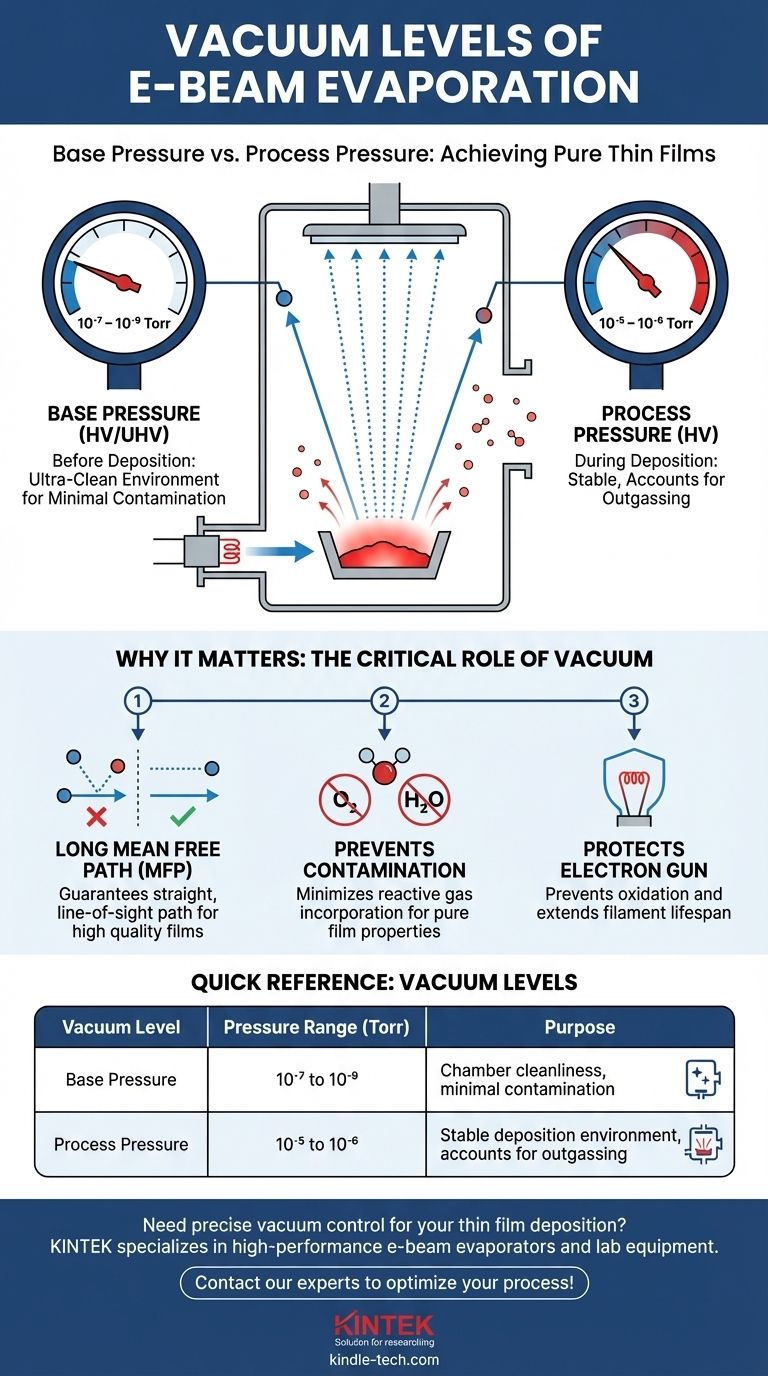

In short, electron beam evaporation requires two distinct vacuum levels. The chamber is first pumped down to a base pressure in the high-vacuum (HV) or ultra-high vacuum (UHV) range, typically between 10⁻⁷ and 10⁻⁹ Torr. During the actual deposition, the pressure rises slightly to a process pressure of around 10⁻⁵ to 10⁻⁶ Torr due to outgassing from the heated material.

The core reason for this demanding vacuum is not just about removing air, but about creating a "collision-free" path. A high vacuum ensures evaporated atoms travel in a straight line from the source to the substrate, preventing contamination and ensuring a pure, high-quality thin film.

Why E-Beam Evaporation Demands a High Vacuum

Understanding the role of the vacuum is fundamental to controlling the quality of your deposited films. The entire process hinges on creating an environment that is as empty as possible for three critical reasons.

The Concept of Mean Free Path (MFP)

The Mean Free Path (MFP) is the average distance a particle can travel before colliding with another particle. In a high-vacuum environment, the MFP is very long, often measuring in meters or even kilometers.

This long MFP is essential. It guarantees that the atoms evaporating from your source material travel in a straight, line-of-sight path directly to your substrate without colliding with residual gas molecules like oxygen or nitrogen.

Without a sufficient vacuum, these collisions would scatter the evaporated atoms, resulting in a non-uniform, low-density film with poor adhesion.

Preventing Contamination and Unwanted Reactions

Residual gases in the chamber, particularly oxygen and water vapor, are highly reactive. When the electron beam heats the source material to its melting point, these reactive gases can easily incorporate into your growing film.

This contamination can drastically alter the film's desired properties, such as its optical transparency, electrical conductivity, or mechanical hardness. A high vacuum minimizes the presence of these contaminants, ensuring the purity of the final film.

Protecting the Electron Gun

The electron beam is generated by a hot tungsten filament. If operated at a poor vacuum level, residual oxygen will rapidly oxidize and destroy this filament, leading to premature failure and costly downtime.

A high vacuum is therefore a prerequisite for the stable and long-term operation of the electron gun itself.

The Two Critical Vacuum Levels Explained

The terms "base pressure" and "process pressure" are not interchangeable. Each represents a distinct stage of the deposition process and tells you something different about the health of your system.

Base Pressure: Setting the Stage for Purity

Base pressure is the lowest pressure the vacuum system can achieve before the deposition process begins. It is a direct measure of the chamber's cleanliness and integrity.

A low base pressure (e.g., 5 x 10⁻⁷ Torr) indicates that the chamber has minimal leaks and has low levels of adsorbed water vapor and other contaminants on its internal surfaces. Reaching a good base pressure is a critical quality gate before starting evaporation.

Process Pressure: The Reality of Deposition

Process pressure is the vacuum level maintained during the actual evaporation. This pressure is always higher than the base pressure.

As the electron beam intensely heats the source material, the material itself (and surrounding hot components) will release trapped gases, a phenomenon known as outgassing. This causes the pressure to rise. A typical, stable process pressure for e-beam evaporation is in the 10⁻⁶ to 10⁻⁵ Torr range.

Understanding the Trade-offs and Pitfalls

Achieving the right vacuum level is a balance between process requirements, equipment capability, and time. Misunderstanding this balance leads to common problems.

The Danger of Insufficient Base Pressure

Starting a deposition run before reaching an adequate base pressure is a frequent mistake driven by a need for speed.

This choice directly compromises film quality. A high base pressure means the chamber is still contaminated with water vapor and other gases, which will inevitably be incorporated into your film, leading to poor adhesion, high stress, and suboptimal optical or electrical properties.

The Cost vs. Quality Equation

Pushing for an ultra-high vacuum (UHV, <10⁻⁹ Torr) provides the absolute purest environment but comes at a significant cost in both equipment (ion pumps, bakeout systems) and time.

For most industrial applications, like optical coatings, a high-vacuum system (10⁻⁷ Torr base pressure) is the practical choice. It provides an excellent balance of film quality and throughput. The key is to match the vacuum level to the sensitivity of the material and the application's requirements.

Leaks vs. Outgassing

Troubleshooting a vacuum problem often comes down to distinguishing between a leak and outgassing. If you isolate the vacuum chamber from the pumps and the pressure rises rapidly and continuously, you likely have a leak.

If the pressure rises quickly at first and then slows down significantly, the problem is more likely outgassing from contaminated surfaces or the source material. This knowledge is crucial for efficient troubleshooting.

Selecting the Right Vacuum for Your Application

Your target vacuum level should be dictated by the desired outcome of your thin film. Use these guidelines to set your goals.

- If your primary focus is high-purity films for R&D or sensitive electronics: Aim for the lowest possible base pressure your system can achieve (ideally 10⁻⁷ Torr or lower) to minimize all sources of contamination.

- If your primary focus is production throughput for applications like optical coatings: A stable process pressure in the low-to-mid 10⁻⁶ Torr range is a robust and widely accepted industry standard.

- If you are troubleshooting film defects like poor adhesion or hazy appearance: Your first step should be to verify you are reaching your target base pressure before every run and perform a leak check if you are not.

Ultimately, mastering vacuum control is the first and most critical step toward achieving repeatable, high-quality thin-film deposition.

Summary Table:

| Vacuum Level | Pressure Range (Torr) | Purpose |

|---|---|---|

| Base Pressure | 10⁻⁷ to 10⁻⁹ | Chamber cleanliness, minimal contamination |

| Process Pressure | 10⁻⁵ to 10⁻⁶ | Stable deposition environment, accounts for outgassing |

Need precise vacuum control for your thin film deposition? KINTEK specializes in high-performance e-beam evaporators and lab equipment designed to deliver the exact vacuum levels required for pure, high-quality films. Whether you're in R&D or production, our solutions ensure repeatable results and enhanced film properties. Contact our experts today to optimize your deposition process!

Visual Guide

Related Products

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- E Beam Crucibles Electron Gun Beam Crucible for Evaporation

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

People Also Ask

- What precautions should be taken during evaporation process? Ensure High-Quality Film Deposition

- What is the process of thermal evaporation? A Guide to Simple, Cost-Effective Thin-Film Deposition

- What is the purpose of an evaporator? The Key Component That Creates Cooling

- What is the thickness of physical vapor deposition? Tailoring PVD Coating for Your Application

- What is the electron beam evaporation technique? Achieve High-Purity Thin Film Deposition

- What is the principle of thermal evaporation method? A Simple Guide to Thin Film Deposition

- Why is an alumina boat and Ti3AlC2 powder bed necessary for Ti2AlC sintering? Protect MAX Phase Purity

- What is the source of electron beam evaporation? The Electron Gun Explained for High-Purity Thin Films