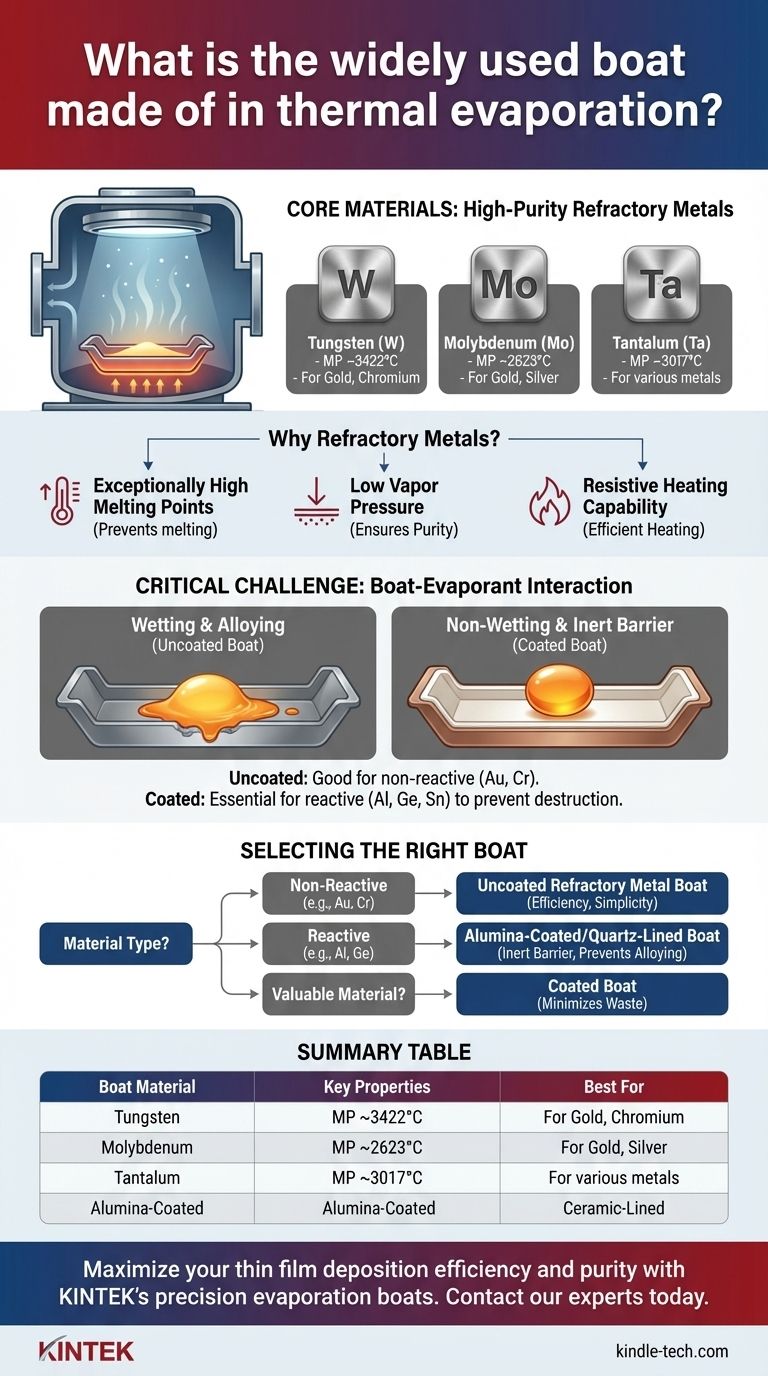

In thermal evaporation, the most widely used boats are fabricated from high-purity refractory metals, primarily tungsten (W), molybdenum (Mo), and tantalum (Ta). These materials are chosen for their extremely high melting points and low vapor pressure, which prevent the boat itself from melting or contaminating the process. For materials that react with or adhere to these metals, a ceramic-coated boat, such as one lined with alumina (Al₂O₃), is used as an inert barrier.

The selection of an evaporation boat is driven by ensuring chemical compatibility and thermal stability between the boat (the heat source) and the material being evaporated (the evaporant). There is no single "best" boat; the right choice depends entirely on the material you intend to deposit.

Why Refractory Metals Are the Standard

The entire thermal evaporation process relies on heating a source material until it evaporates within a high-vacuum chamber. The boat must facilitate this process without becoming part of it.

Exceptionally High Melting Points

The boat must remain solid at temperatures far exceeding the evaporation point of the source material. Tungsten (melting point ~3422°C), Tantalum (~3017°C), and Molybdenum (~2623°C) are ideal for evaporating common metals like Gold (~2856°C boiling point) or Chromium (~2671°C boiling point).

Low Vapor Pressure

A material's vapor pressure is its tendency to evaporate at a given temperature. Refractory metals have exceptionally low vapor pressures, ensuring that only the target material evaporates, which is critical for creating a pure thin film.

Resistive Heating Capability

These boats are heated by passing a high electrical current directly through them. Their inherent electrical resistance generates the intense heat required for evaporation, making the system efficient and controllable.

The Critical Role of Boat-Evaporant Interaction

The most common point of failure or inefficiency in thermal evaporation is a poor interaction between the molten evaporant and the boat material.

The Problem of "Wetting"

Wetting occurs when a molten material spreads across and adheres to a solid surface. In this context, if an evaporant "wets" the boat, it can alloy with the metal, dissolving and destroying the boat and ruining the deposition process.

When to Use an Uncoated Metal Boat

For materials that do not readily alloy with the boat, a simple, uncoated refractory metal boat is the most efficient choice. For example, evaporating Gold (Au) or Chromium (Cr) from a molybdenum boat is a standard, reliable process.

When to Use a Coated Boat

For evaporants that exhibit high adhesion, such as aluminum on tungsten, an inert barrier is required. Alumina-coated boats provide a ceramic surface that resists wetting. This prevents the molten evaporant from making direct contact with the underlying refractory metal, protecting the boat and ensuring a clean evaporation.

Understanding the Trade-offs

Choosing a boat involves balancing performance, cost, and the specific needs of your material.

Power Consumption

As noted in the references, an alumina coating acts as a thermal insulator. This means an alumina-coated boat requires a higher electrical current to reach the same temperature as an uncoated boat, increasing power consumption.

Material Consumption and Cost

A coated boat's non-wetting surface is highly advantageous when working with valuable materials like gold. Because the molten material beads up instead of spreading out, evaporation is more efficient and less material is left behind in the boat after the process.

Boat Lifespan

Using the wrong boat can be costly. If an evaporant alloys with an uncoated boat, the boat will be destroyed, often in a single run. Selecting the correct boat—even if it's a more expensive coated version—dramatically increases its lifespan and prevents failed deposition runs.

Selecting the Right Boat for Your Material

Your choice should be dictated by the chemical properties of the material you are depositing.

- If your primary focus is evaporating non-reactive metals (like Au, Ag, Cr): Start with an uncoated refractory metal boat, such as molybdenum or tungsten, for maximum thermal efficiency and simplicity.

- If your primary focus is evaporating reactive materials (like Al, Ge, Sn): You must use a boat with an inert liner, such as an alumina-coated or quartz-lined boat, to prevent destructive source-evaporant interaction.

- If your primary focus is maximizing yield of a valuable material: Consider an alumina-coated boat to minimize wetting and ensure as much of the source material as possible is evaporated effectively.

Ultimately, selecting the correct boat is a foundational step for achieving a repeatable and high-purity thermal evaporation process.

Summary Table:

| Boat Material | Key Properties | Best For Evaporating |

|---|---|---|

| Tungsten (W) | Melting point ~3422°C, low vapor pressure | Gold, Chromium (non-reactive metals) |

| Molybdenum (Mo) | Melting point ~2623°C, good thermal conductivity | Gold, Silver, Chromium |

| Tantalum (Ta) | Melting point ~3017°C, excellent corrosion resistance | Various metals with low reactivity |

| Alumina-Coated | Inert ceramic barrier, prevents wetting | Aluminum, Germanium, Tin (reactive materials) |

Maximize your thin film deposition efficiency and purity with KINTEK's precision evaporation boats. Whether you're working with reactive materials like aluminum or valuable metals like gold, our range of high-purity tungsten, molybdenum, tantalum, and alumina-coated boats ensures chemical compatibility and thermal stability for your lab's specific needs. Contact our experts today to select the ideal boat for your thermal evaporation process and achieve repeatable, high-yield results.

Visual Guide

Related Products

- Tungsten Evaporation Boat for Thin Film Deposition

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Folding Molybdenum Tantalum Boat With or Without Cover

- Evaporation Boat for Organic Matter

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- How thin film is prepared using thermal evaporation technique? A Guide to High-Purity Deposition

- What is thermal evaporation process? A Guide to Simple, High-Purity Thin Film Deposition

- What are the disadvantages of thermal evaporation method? Key Limitations in Purity and Performance

- What is the thermal evaporation technique in a vacuum? A Guide to High-Purity Thin-Film Deposition

- What are the applications of thermal evaporation? A Guide to Thin-Film Deposition for Electronics & Coatings

- What are the different types of evaporators in food engineering? Choose the Right System for Your Product

- Why is sputtering deposition slower than evaporation? Unpacking the Physics of PVD Rates

- What is e-beam evaporation? Achieve High-Purity Thin Film Deposition for Your Lab