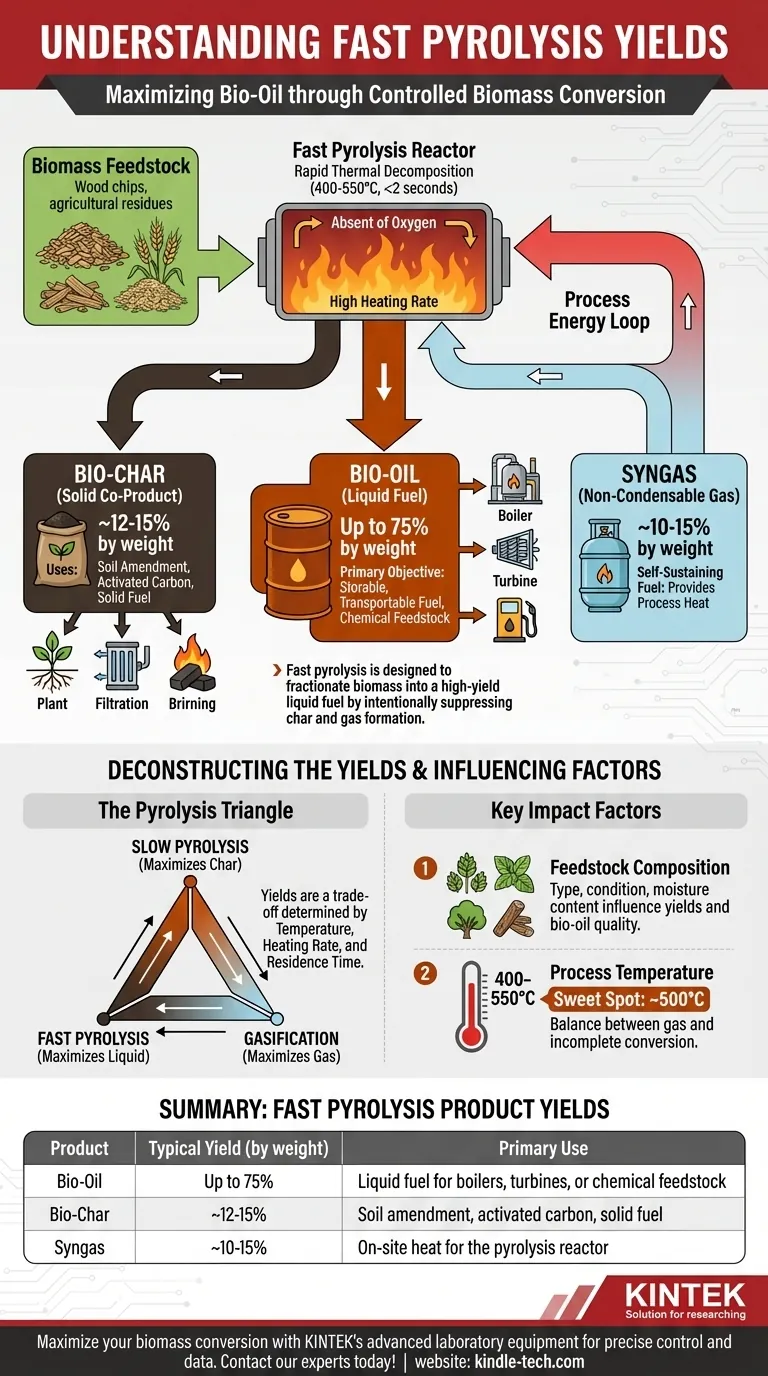

In practice, fast pyrolysis is a thermochemical process specifically engineered to maximize the liquid product, known as bio-oil. A well-optimized system typically converts biomass into up to 75% bio-oil by weight, with the remainder yielding approximately 12% bio-char and 13% non-condensable syngas. These yields are not fixed; they are the direct result of precise process control.

Fast pyrolysis is not simply about heating biomass. It is a carefully controlled, rapid thermal decomposition process designed to fractionate biomass into a high-yield liquid fuel (bio-oil) by intentionally suppressing the reactions that would otherwise produce more char and gas.

Understanding the Fast Pyrolysis Process

The Core Principle: Rapid Thermal Decomposition

Fast pyrolysis involves heating biomass feedstock to moderate temperatures, typically between 400-550°C (750-1020°F). This occurs in a reactor completely absent of oxygen to prevent combustion.

The defining characteristic of this process is speed. The biomass has a very short residence time in the reactor—often less than two seconds—coupled with a very high heating rate. This rapid conversion is key to maximizing the liquid yield.

The Three Primary Products

The process splits the solid biomass into three distinct products:

- Bio-oil: A dense, dark liquid that captures the bulk of the energy from the original biomass. It is the main product.

- Bio-char: A solid, carbon-rich material similar to charcoal.

- Syngas: A mix of non-condensable, flammable gases (like carbon monoxide, hydrogen, and methane).

Why "Fast" Is the Critical Factor

The speed of the process is what separates fast pyrolysis from other thermal methods. Slow pyrolysis, which takes hours, breaks down the biomass structures more completely, maximizing the solid bio-char yield.

In contrast, fast pyrolysis rapidly vaporizes the biomass and then quickly quenches (cools) the vapors into a liquid. This short duration prevents the vapor molecules from further breaking down (or "cracking") into smaller, gaseous molecules or repolymerizing into solid char.

Deconstructing the Product Yields

Bio-Oil: The Primary Objective

The goal of fast pyrolysis is to produce a storable, transportable liquid fuel. With yields reaching up to 75% of the input biomass weight, bio-oil represents the most significant output.

This liquid can be used directly as a fuel for industrial boilers and turbines or can be upgraded into higher-value transportation fuels and chemical feedstocks.

Bio-Char: The Solid Co-Product

Typically, around 12-15% of the biomass is converted into bio-char. While a smaller fraction of the output, this material has significant value.

It can be used as a potent soil amendment to improve fertility and water retention, as a feedstock for producing activated carbon for filtration, or burned as a solid fuel.

Syngas: The Self-Sustaining Fuel

The remaining 10-15% of the product stream is syngas. While this has the lowest mass yield, it plays a critical role in the process's overall efficiency.

In most modern facilities, this stream of flammable gas is captured and burned on-site to provide the heat required for the pyrolysis reactor. This creates a partially self-sustaining energy loop, reducing the need for external fuel and lowering operational costs.

Understanding the Trade-offs and Influencing Factors

The Pyrolysis Triangle

Think of thermal conversion as a triangle of outcomes. Slow pyrolysis maximizes char, fast pyrolysis maximizes liquid, and gasification (a related process at higher temperatures) maximizes gas. The yields you achieve are a direct trade-off determined by temperature, heating rate, and residence time.

Impact of Feedstock

The type and condition of the biomass feedstock are crucial. Wood chips, agricultural residues (like corn stover), and energy grasses all have different chemical compositions (cellulose, hemicellulose, lignin) and moisture content. These variations directly influence the final product yields and the chemical quality of the bio-oil.

Impact of Process Temperature

While the general range is 400-550°C, small adjustments have a major impact. Operating at the lower end of this range may produce less gas but risk incomplete conversion. Pushing to higher temperatures can increase gas yield at the expense of your target bio-oil. The "sweet spot" is typically around 500°C.

Making the Right Choice for Your Goal

Before evaluating fast pyrolysis, it is essential to clarify your primary objective. The process can be tuned, but it is fundamentally designed for one main purpose.

- If your primary focus is producing renewable liquid fuel: Fast pyrolysis is the optimal thermal process, as it is specifically designed to maximize bio-oil yield.

- If your primary focus is creating a stable soil amendment: A slower pyrolysis process would be more effective, as its longer residence time is optimized to produce a higher yield of bio-char.

- If your primary focus is energy self-sufficiency: The syngas co-product from fast pyrolysis can often be used to power the process, reducing external energy inputs and improving the overall energy balance.

Understanding these distinct product yields is the first step toward harnessing biomass as a flexible and valuable renewable resource.

Summary Table:

| Product | Typical Yield (by weight) | Primary Use |

|---|---|---|

| Bio-Oil | Up to 75% | Liquid fuel for boilers, turbines, or chemical feedstock |

| Bio-Char | ~12-15% | Soil amendment, activated carbon, solid fuel |

| Syngas | ~10-15% | On-site heat for the pyrolysis reactor |

Ready to optimize your biomass conversion process?

At KINTEK, we specialize in advanced laboratory equipment for pyrolysis research and development. Whether you're scaling up bio-oil production or analyzing feedstock efficiency, our precise reactors and analytical tools provide the control and data you need to maximize yields.

Let KINTEK empower your renewable energy innovations. Contact our experts today to discuss your specific lab equipment needs.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time