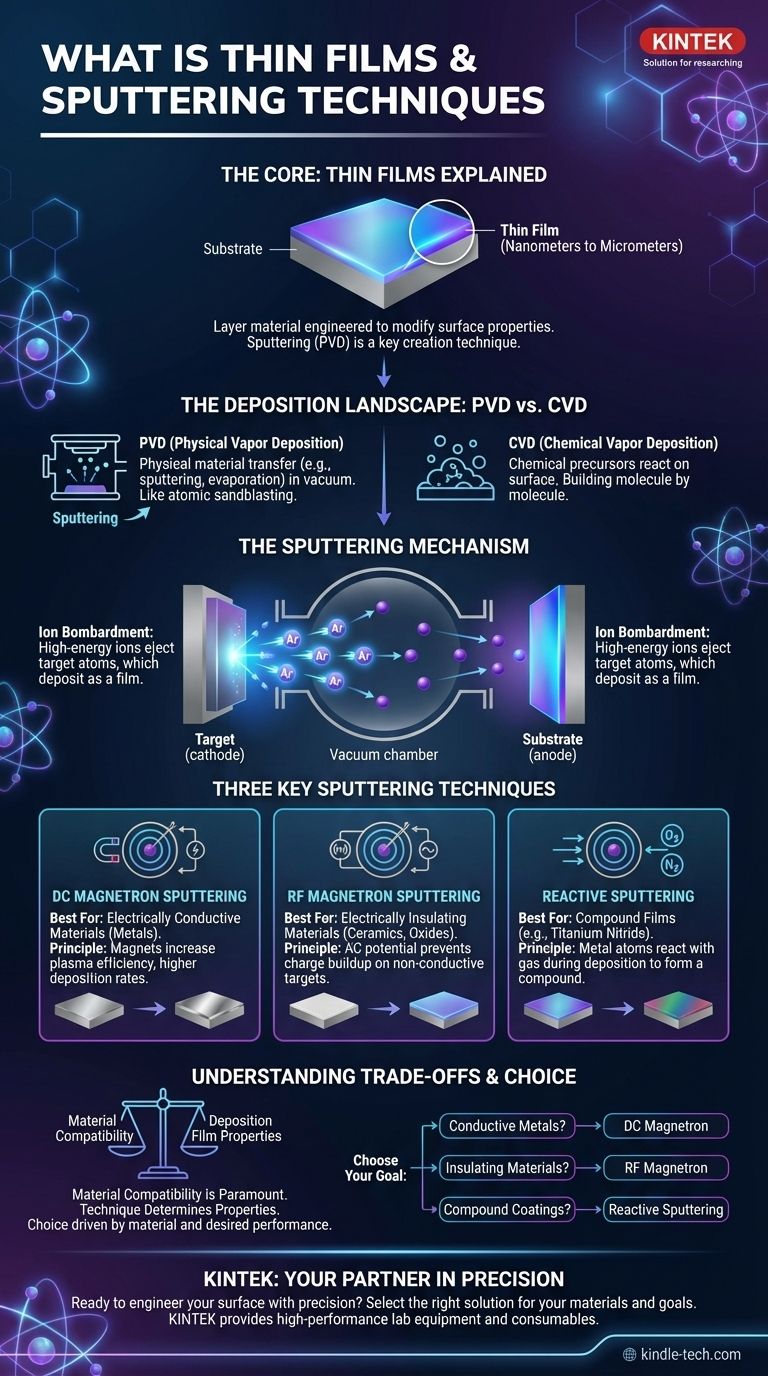

At its core, a thin film is a layer of material ranging from a few nanometers to several micrometers in thickness, engineered to modify the surface properties of an object. Sputtering is a dominant technique for creating these films and falls under the category of Physical Vapor Deposition (PVD). It works by bombarding a source material (a "target") with energetic ions, which ejects or "sputters" atoms from the target that then deposit onto a substrate, forming the desired thin film.

Understanding sputtering isn't just about knowing the process; it's about recognizing it as a tool for atomic-level construction. The specific technique you choose dictates which materials you can use and directly engineers the final properties of your film, from its electrical conductivity to its mechanical hardness.

The Landscape of Thin Film Deposition

To understand sputtering, you must first see where it fits within the broader field of thin film creation. The methods are generally divided into two major families based on how they transport material to the substrate.

The Two Major Families: PVD and CVD

The two primary deposition techniques are Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD).

PVD processes, including sputtering, use physical mechanisms like high-energy bombardment or evaporation to transfer material from a source to a substrate in a vacuum. Think of it as an atomic-scale sandblasting and coating process.

CVD processes use volatile precursor chemicals that react or decompose on the substrate's surface to form the film. This is more akin to building the film layer molecule by molecule through controlled chemical reactions.

Where Sputtering Fits

Sputtering is a PVD technique. It is distinct from other PVD methods like evaporation, which involves simply heating a material until it turns into a vapor. Sputtering is a more energetic process, leading to denser and more adherent films.

A Deeper Look at Sputtering Techniques

All sputtering operates on the same basic principle, but different variations have been developed to handle different materials and achieve specific film characteristics.

The Core Mechanism: Ion Bombardment

The process begins by creating a low-pressure plasma, typically from an inert gas like Argon. A high voltage is applied between the substrate and the target material, causing the gas to ionize.

These positively charged Argon ions are accelerated into the negatively charged target. The high-energy impact physically knocks atoms loose from the target, which then travel through the vacuum chamber and condense on the substrate as a thin film.

DC Magnetron Sputtering

This is the workhorse technique for depositing electrically conductive materials, such as metals.

It uses powerful magnets behind the target (a "magnetron") to trap electrons in a magnetic field. This greatly increases the efficiency of the ionization process, resulting in a more stable plasma and higher deposition rates compared to simple DC sputtering.

RF Magnetron Sputtering

When you need to deposit electrically insulating materials (dielectrics), like ceramics or oxides, DC sputtering fails. Charge builds up on the surface of the insulating target, effectively stopping the ion bombardment.

RF (Radio Frequency) sputtering solves this by using an alternating AC potential. The rapid switching of the electric field prevents charge accumulation, allowing for the continuous sputtering of non-conductive materials.

Reactive Sputtering

This technique is used to create compound films. It involves sputtering a metallic target in a vacuum chamber that contains a mixture of inert and reactive gases (like oxygen or nitrogen).

As the sputtered metal atoms travel toward the substrate, they react with the gas to form a compound. For example, sputtering a titanium target in a nitrogen atmosphere creates a hard, gold-colored Titanium Nitride (TiN) coating.

Understanding the Trade-offs

Choosing a sputtering technique is a matter of balancing material requirements, process complexity, and desired film properties. The technique is not just a delivery method; it is a primary factor in the film's performance.

Material Compatibility Is Paramount

The most critical factor is the electrical conductivity of your target material. DC sputtering is simpler and generally faster, but it is strictly limited to conductive targets. RF sputtering offers the versatility to deposit virtually any material but is often slower and requires more complex power supplies.

Deposition Control and Film Quality

Sputtering provides excellent control over film thickness and uniformity across large areas. Because the sputtered atoms have high kinetic energy, they create films that are typically much denser and have stronger adhesion to the substrate compared to thermal evaporation.

The Technique Determines the Properties

The deposition parameters—such as gas pressure, power, and substrate temperature—have a direct and significant impact on the film's final characteristics. Properties like crystal structure, internal stress, density, and resistivity are all determined by how the film is grown.

Making the Right Choice for Your Goal

Your decision must be driven by the material you intend to deposit and the performance you require from the final film.

- If your primary focus is depositing conductive metals like aluminum or titanium: DC magnetron sputtering is your most efficient and cost-effective choice.

- If your primary focus is depositing insulating materials like silicon dioxide (SiO2) or ceramics: RF magnetron sputtering is the necessary method to overcome target charging issues.

- If your primary focus is creating hard, functional compound coatings like titanium nitride (TiN): Reactive sputtering gives you the power to synthesize the compound material during the deposition process itself.

By understanding these fundamental techniques and their trade-offs, you can select the right process to precisely engineer the properties of your surface.

Summary Table:

| Technique | Best For | Key Principle |

|---|---|---|

| DC Magnetron Sputtering | Electrically Conductive Materials (Metals) | Uses magnets to increase plasma efficiency for high deposition rates. |

| RF Magnetron Sputtering | Electrically Insulating Materials (Ceramics, Oxides) | Uses radio frequency to prevent charge buildup on non-conductive targets. |

| Reactive Sputtering | Compound Films (e.g., Titanium Nitride) | Sputters a metal target in a reactive gas atmosphere to form a compound. |

Ready to engineer your surface with precision? The right sputtering technique is critical for achieving the desired electrical, mechanical, and chemical properties in your thin film. KINTEK specializes in providing high-performance lab equipment and consumables for all your thin film deposition needs, from research to production.

Let our experts help you select the ideal sputtering solution for your specific materials and goals.

Contact KINTEK today to discuss your project and discover how we can enhance your laboratory's capabilities.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Cylindrical Press Mold with Scale for Lab

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- What are the advantages and disadvantages of sputtering techniques? Achieve Superior Thin-Film Deposition

- What is vapor deposition process? A Guide to CVD and PVD Thin-Film Coating

- Why is argon-rich gas phase chemistry used for UNCD growth? Unlock Precision Nano-Diamond Synthesis

- What functions do ceramic insulation materials perform in a CVD reactor? Enhancing Thermal & Mechanical Stability

- What are deposition products? Master the PVD and CVD Methods for Superior Thin Films

- Why is DLI-MOCVD Required for Long Fuel Cladding Tubes? Ensure Uniform Internal Coating for Nuclear Safety

- What are the applications of thin film interference? Control Light & Measure with Nanometer Precision

- What is the difference between sputtering and ion plating? Choose the Right PVD Coating for Your Application