In short, ultra fast pyrolysis is an advanced thermochemical process that heats biomass at extremely high rates and for a very short duration—typically less than 500 milliseconds. Unlike conventional fast pyrolysis which aims to produce liquid bio-oil, the primary goal of this ultra-rapid method is to maximize the yield of valuable chemical intermediates and fuel gases by preventing the secondary reactions that form complex liquids.

The critical distinction is one of intent. While fast pyrolysis is optimized for creating a liquid fuel substitute (bio-oil), ultra fast pyrolysis is a precision tool engineered to convert biomass directly into high-value chemical feedstocks like olefins and syngas.

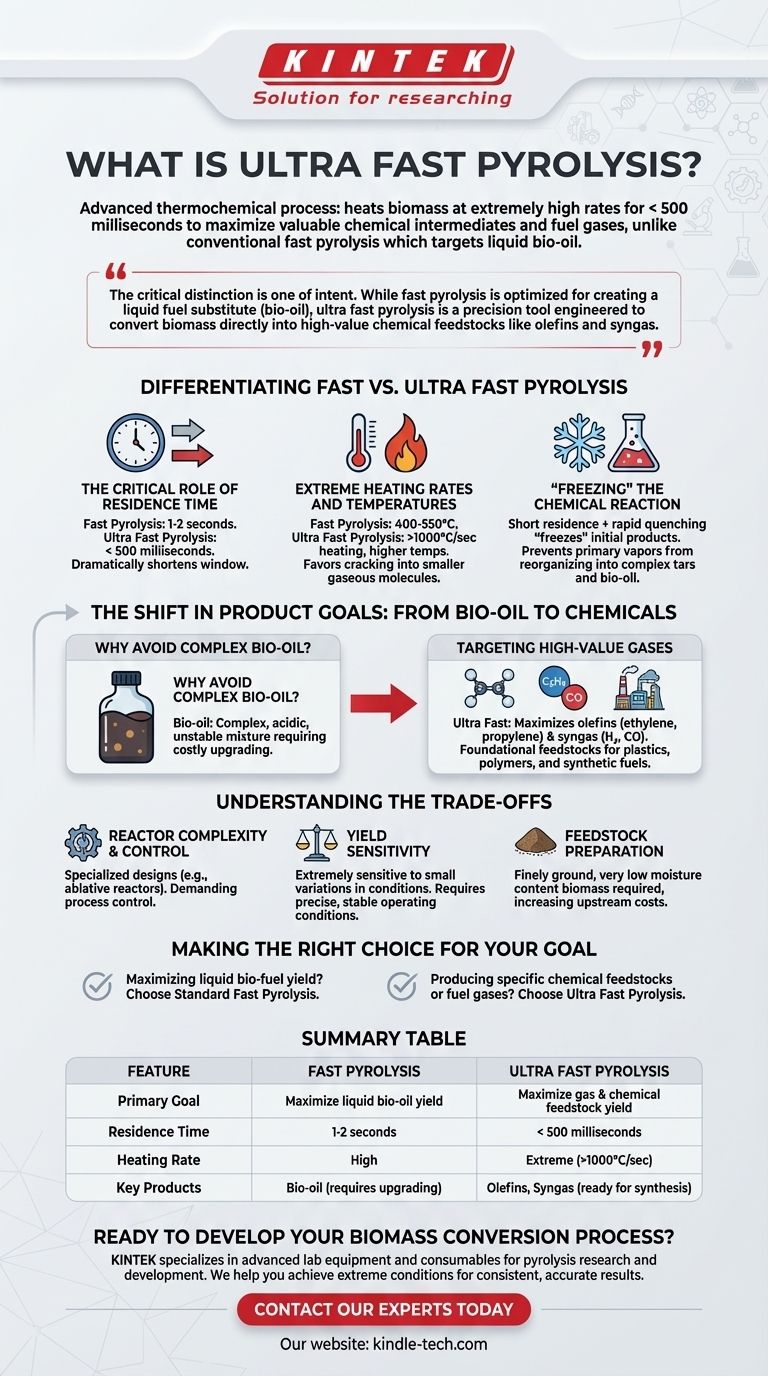

Differentiating Fast vs. Ultra Fast Pyrolysis

The term "ultra fast" is not just a marketing descriptor; it signifies fundamental changes in reaction conditions that completely alter the process outcome. This is achieved by manipulating three key variables.

The Critical Role of Residence Time

Standard fast pyrolysis processes operate with a vapor residence time of around 1 to 2 seconds.

Ultra fast pyrolysis dramatically shortens this window to under 500 milliseconds. This incredibly brief exposure to high heat is the most important factor distinguishing the two methods.

Extreme Heating Rates and Temperatures

To accomplish decomposition in milliseconds, the heating rates must be exceptionally high, often exceeding 1000°C per second.

While conventional fast pyrolysis operates between 400-550°C, ultra fast variants often push temperatures higher. This further favors the cracking of biomass into smaller, gaseous molecules.

"Freezing" the Chemical Reaction

The combination of short residence time and rapid quenching (cooling) effectively "freezes" the initial reaction products.

This prevents the primary vapors from reorganizing into the complex, heavy molecules that constitute tars and bio-oil. The process essentially intercepts the desired chemicals before they can degrade into a less valuable liquid mixture.

The Shift in Product Goals: From Bio-oil to Chemicals

The engineering complexity of ultra fast pyrolysis is driven by a strategic shift away from producing bio-oil and toward creating more valuable and easily processed chemical building blocks.

Why Avoid Complex Bio-oil?

While useful, the bio-oil from fast pyrolysis is a complex mixture that is often acidic, unstable, and requires significant, costly upgrading before it can be used as a drop-in fuel.

Targeting High-Value Gases

Ultra fast pyrolysis is specifically designed to maximize the yield of gases like olefins (ethylene, propylene) and syngas (a mixture of hydrogen and carbon monoxide).

These products are foundational feedstocks for the chemical industry, used in the production of plastics, polymers, and synthetic fuels. This transforms biomass from a simple crude fuel source into a precursor for advanced materials.

Understanding the Trade-offs

The precision of ultra fast pyrolysis introduces significant engineering and operational challenges compared to conventional methods.

Reactor Complexity and Control

Achieving millisecond-scale residence times and extreme heating rates requires highly specialized and complex reactor designs, such as ablative or vortex reactors. Process control is far more demanding.

Yield Sensitivity

The product distribution is extremely sensitive to small variations in temperature, heating rate, and residence time. Maintaining consistent output requires precise and stable operating conditions.

Feedstock Preparation

Like most pyrolysis methods, this process requires biomass that is finely ground and has very low moisture content, adding to the upstream processing costs.

Making the Right Choice for Your Goal

Selecting the appropriate pyrolysis technology depends entirely on your desired end product and operational capabilities.

- If your primary focus is maximizing liquid bio-fuel yield for energy or heating: Standard fast pyrolysis is the more mature, established, and direct pathway.

- If your primary focus is producing specific chemical feedstocks or fuel gases for synthesis: Ultra fast pyrolysis provides a unique and powerful method to directly target these high-value outputs.

Ultimately, understanding the fundamental relationship between reaction time and product composition is the key to unlocking the full potential of biomass conversion.

Summary Table:

| Feature | Fast Pyrolysis | Ultra Fast Pyrolysis |

|---|---|---|

| Primary Goal | Maximize liquid bio-oil yield | Maximize gas & chemical feedstock yield |

| Residence Time | 1-2 seconds | < 500 milliseconds |

| Heating Rate | High | Extreme (>1000°C/sec) |

| Key Products | Bio-oil (requires upgrading) | Olefins, Syngas (ready for synthesis) |

Ready to develop your biomass conversion process?

Whether you are researching reactor design or scaling up production of high-value chemicals, having the right laboratory equipment is critical for precise temperature and reaction control.

KINTEK specializes in advanced lab equipment and consumables for pyrolysis research and development. We can help you build a reliable system to achieve the extreme conditions required for ultra fast pyrolysis, ensuring consistent and accurate results for your innovative projects.

Contact our experts today to discuss how we can support your laboratory's specific needs in biomass conversion and thermochemical processing.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- Why do you heat treat in a vacuum? Achieve Perfect Surface Finish and Material Integrity

- Why is a laboratory vacuum drying oven necessary for single-crystal cathode powders? Ensure Peak Material Stability

- Why is a vacuum furnace or an atmosphere furnace using nitrogen essential for CFRP pyrolysis? Preserve Fiber Integrity

- Why is a vacuum drying oven required for Si-FG post-treatment? Preserving Chemical Integrity of Graphene

- How are vacuum furnaces categorized based on their degree of vacuum? Select the Right Level for Your Process

- What are the advantages of a vacuum furnace? Achieve Superior Purity and Control in Heat Treatment

- What is the time and temperature of heat treatment? A Guide to Tailoring Material Properties

- What is the operating mechanism of a vacuum drying oven in nanomaterials? Preserve Pore Integrity & Prevent Oxidation