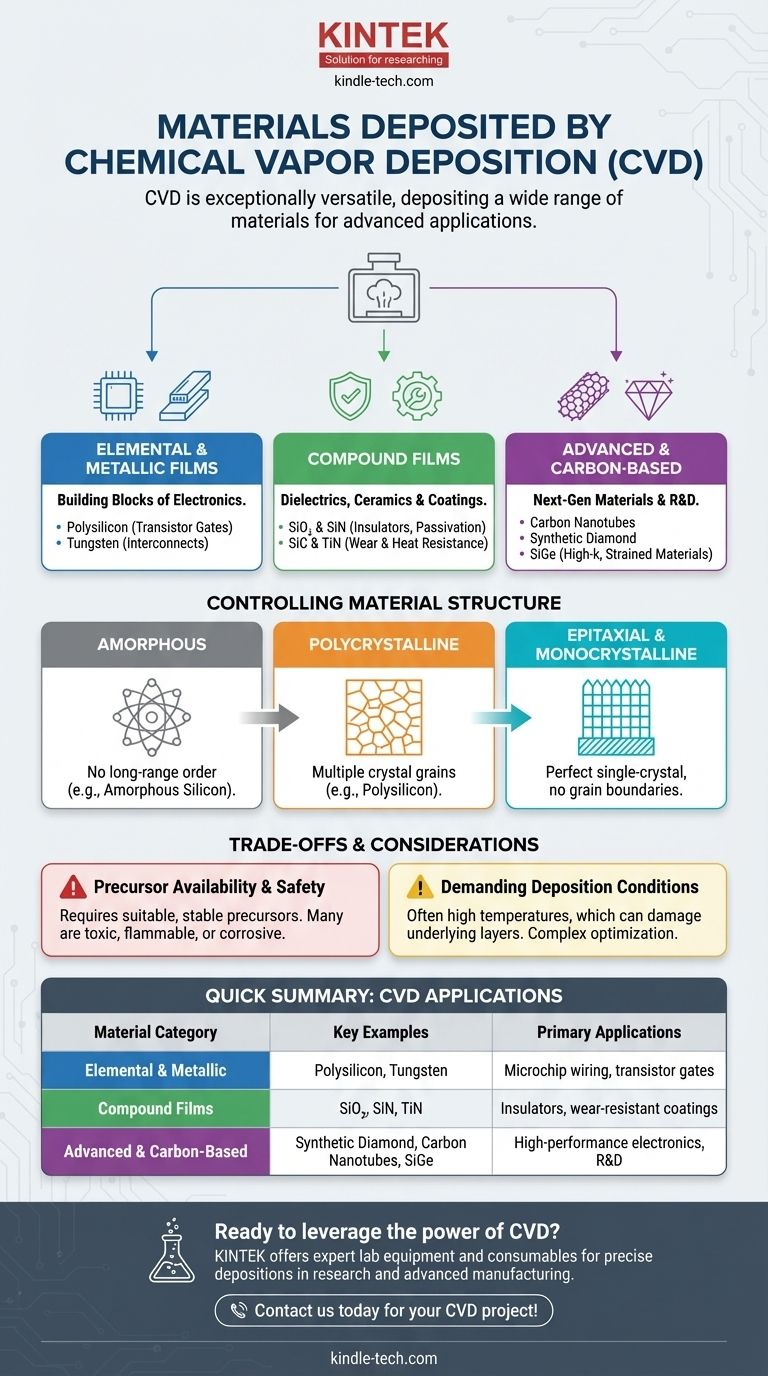

At its core, Chemical Vapor Deposition (CVD) is remarkably versatile, capable of depositing an exceptionally wide range of materials. The process is not limited to a single class of substance; instead, it can be used to create thin films of elemental materials like silicon and tungsten, compound insulators and ceramics like silicon nitride and titanium nitride, and even exotic materials like synthetic diamond and carbon nanotubes.

The true power of CVD is not just the extensive list of materials it can deposit, but its precise control over the material’s final structural form—from amorphous to perfect single-crystal—and its resulting physical properties. This makes it an indispensable tool for advanced manufacturing.

The Three Pillars of CVD Materials

The materials deposited by CVD can be broadly organized into three fundamental categories, each serving critical functions in technology and industry.

Elemental and Metallic Films

These are often the building blocks of electronic devices. CVD is a primary method for depositing conductive films that form the wiring and components of microchips.

Common examples include polysilicon, which is fundamental for creating transistor gates, and metals like tungsten, used to fill vias and create reliable electrical interconnects between layers in a semiconductor device.

Compound Films: Dielectrics and Ceramics

This is arguably the most diverse category. CVD excels at creating compound materials that act as insulators (dielectrics) or protective, hard coatings (ceramics).

In microelectronics, films like silicon dioxide (SiO₂) and silicon nitride (SiN) are ubiquitous, serving as insulators, passivation layers, and etch masks. Complex stacks like oxide-nitride-oxide (ONO) are also standard.

For industrial applications, hard ceramics like silicon carbide (SiC) and titanium nitride (TiN) are deposited on machine tools, engine components, and turbine blades to provide extreme wear and heat resistance.

Advanced and Carbon-Based Materials

CVD is at the forefront of materials science research, enabling the synthesis of next-generation materials with unique properties.

This includes various forms of carbon, such as carbon fiber, carbon nanotubes, and even films of synthetic diamond. The process is also critical for creating high-k dielectrics and strained materials like silicon-germanium (SiGe), which are essential for pushing the performance limits of modern transistors.

Beyond Composition: Controlling Material Structure

A material's performance depends as much on its atomic structure as its chemical composition. CVD provides an unparalleled level of control over this structure, a key reason for its widespread adoption.

Amorphous Films

An amorphous film has no long-range atomic order, similar to glass. This structure is often desired for its uniformity and specific optical or electronic properties. A classic example is amorphous silicon, used widely in solar panels and the thin-film transistors that power flat-panel displays.

Polycrystalline Films

A polycrystalline film is composed of many small, individual crystal grains with random orientations. Polysilicon is the quintessential example, forming the gate electrode in billions of transistors. The size and orientation of these grains can be controlled to tune the film's electrical properties.

Epitaxial & Monocrystalline Films

Epitaxy is the process of growing a crystalline film that perfectly mimics the crystal structure of the underlying substrate. This results in a monocrystalline, or single-crystal, layer free of grain boundaries. This defect-free structure is essential for high-performance applications where electron mobility must be maximized.

Understanding the Trade-offs

While incredibly powerful, CVD is not without its constraints. The choice to use it involves practical considerations and technical limitations.

Precursor Availability and Safety

The single biggest constraint of CVD is the need for a suitable precursor chemical. This precursor must be a gas (or a liquid/solid that can be vaporized) that is stable at room temperature but will decompose or react on the substrate surface at a higher temperature. Many of these precursors are highly toxic, flammable, or corrosive, requiring stringent safety protocols.

Demanding Deposition Conditions

Traditional CVD processes often require very high temperatures to drive the necessary chemical reactions. This can damage or alter underlying layers that have already been deposited on a substrate, limiting its application in some multi-step fabrication sequences.

Film Property Control

While CVD offers great control, achieving specific properties like low film stress or a desired refractive index requires careful tuning of multiple process parameters, including temperature, pressure, and gas flow rates. This optimization can be complex and time-consuming.

Making the Right Choice for Your Application

The specific CVD material you choose is dictated entirely by your end goal.

- If your primary focus is semiconductor fabrication: You will primarily use CVD for silicon (in all its forms), silicon dioxide, silicon nitride, and conductive metals like tungsten.

- If your primary focus is protective coatings: You should explore hard ceramics like silicon carbide, titanium nitride, and rare-earth oxides for superior wear, corrosion, and thermal resistance.

- If your primary focus is advanced R&D: CVD is your tool for creating novel materials like carbon nanotubes, synthetic diamonds, or tailored high-k dielectrics for next-generation devices.

Ultimately, the vast library of materials available through CVD is a direct result of its foundational chemical principles, enabling continuous innovation across countless industries.

Summary Table:

| Material Category | Key Examples | Primary Applications |

|---|---|---|

| Elemental & Metallic Films | Polysilicon, Tungsten | Microchip wiring, transistor gates, electrical interconnects |

| Compound Films (Dielectrics & Ceramics) | Silicon Dioxide (SiO₂), Silicon Nitride (SiN), Titanium Nitride (TiN) | Insulators, passivation layers, wear-resistant coatings |

| Advanced & Carbon-Based Materials | Synthetic Diamond, Carbon Nanotubes, Silicon-Germanium (SiGe) | High-performance electronics, R&D, thermal management |

Ready to leverage the power of CVD for your specific material needs? Whether you're developing next-generation semiconductors, creating durable protective coatings, or pushing the boundaries of materials science, KINTEK's expertise in lab equipment and consumables can help you achieve precise, high-quality depositions. Our solutions are tailored to meet the rigorous demands of laboratories and advanced manufacturing. Contact us today to discuss how we can support your project with the right CVD technology and materials!

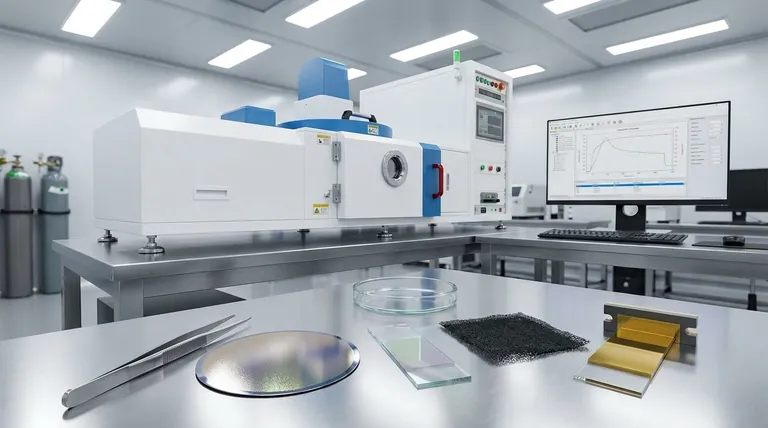

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- CVD Diamond Domes for Industrial and Scientific Applications

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the thermal CVD technique? The High-Temperature Secret to Superior Coatings

- How much does CVD diamond equipment cost? A Breakdown of Investment from Lab to Production

- What is chemical vapor deposition for nanoparticle synthesis? Build High-Purity Nanomaterials from the Ground Up

- What is the primary function of a Chemical Vapor Deposition (CVD) system in the fabrication of SiCf/SiC composites?

- What is the difference between LPCVD and PECVD? Heat vs. Plasma for Thin-Film Deposition

- What are the sequential steps involved in the Chemical Vapor Deposition (CVD) process? Master the 6-Phase Lifecycle

- What is the difference between evaporation and sputtering? Choose the Right Thin Film Deposition Method

- What is the manner for depositing extremely controlled thin films? Achieve Atomic-Level Precision with ALD