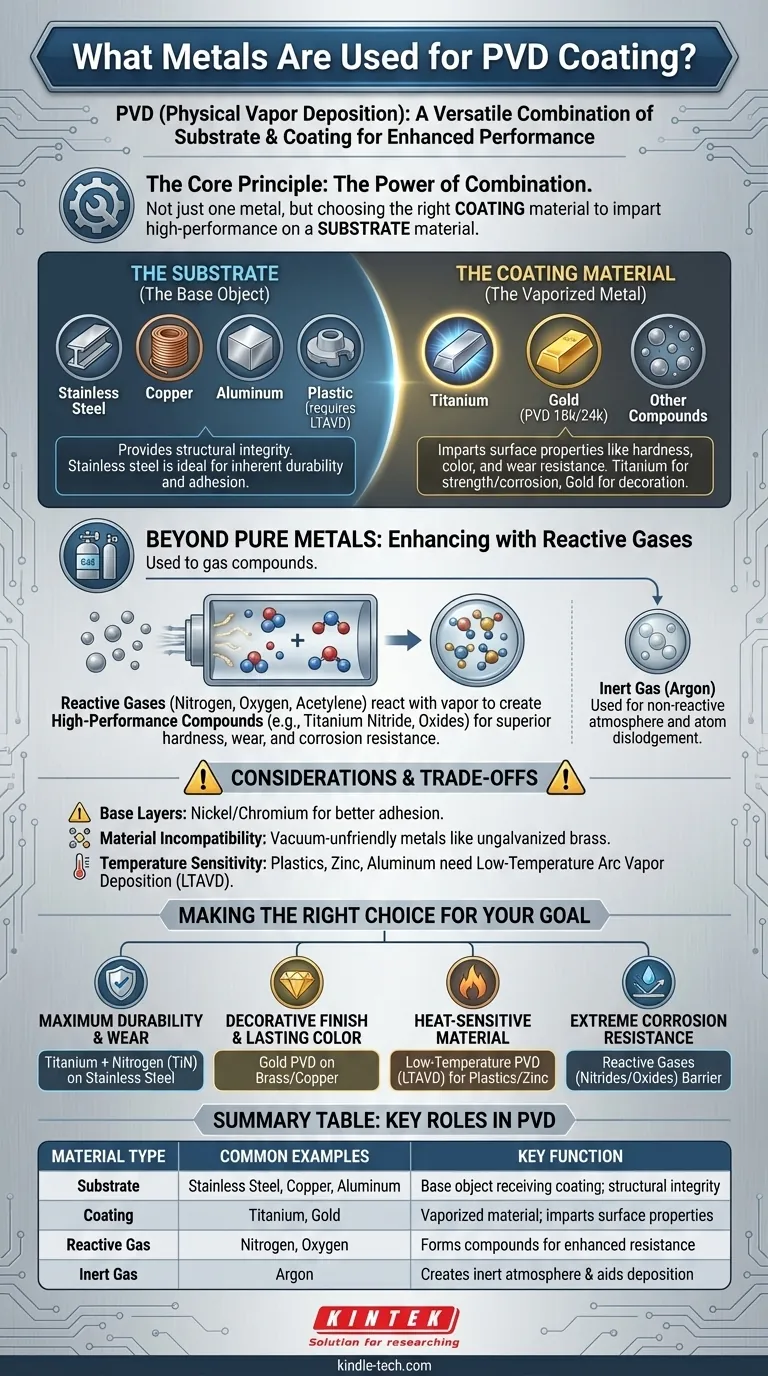

While titanium and gold are the most well-known metals, the real answer is that Physical Vapor Deposition (PVD) is a versatile coating process compatible with a wide range of materials. The specific metal or compound used for the coating is selected based on the desired final properties, such as durability, color, and corrosion resistance. The material being coated (the substrate) is just as important as the coating material itself.

The core principle of PVD is not about a single metal, but about choosing a specific coating material (like titanium) to impart high-performance characteristics onto a different substrate material (like stainless steel). The magic is in the combination.

The Role of Metal: Substrate vs. Coating

To understand what metals are used, it's critical to distinguish between the two key components in the PVD process.

The Substrate (The Object Being Coated)

The substrate is the base part or workpiece that receives the coating. Many metals are excellent substrates.

Suitable substrate materials include all families of steel, especially stainless steels and other high-alloy steels.

Non-ferrous metals like copper and aluminum and their alloys can also be effectively coated. Even materials like plastic can serve as a substrate, though they require a specialized process.

Stainless steel is a particularly advantageous substrate because it is inherently durable, corrosion-resistant, and provides excellent adherence without needing an intermediate base layer.

The Coating Material (The Vaporized Metal)

This is the material that is vaporized and deposited onto the substrate. The choice here directly influences the final product's performance and appearance.

Titanium is a popular choice for PVD coatings due to its exceptional strength, light weight, and high corrosion resistance. It is a workhorse in demanding industries like aerospace and medical.

Gold is frequently used for decorative applications where a brilliant, durable finish is required. PVD can apply various purities, including 18k or 24k gold, over substrates like brass or copper.

Beyond Pure Metals: The Use of Reactive Gases

The PVD process is often enhanced by introducing reactive gases into the vacuum chamber.

Creating High-Performance Compounds

Gases like nitrogen, oxygen, or acetylene react with the vaporized metal source.

This reaction forms new compounds on the substrate's surface, such as titanium nitride or oxides.

These compounds are often harder and more protective than the pure metal, offering superior resistance to wear, corrosion, and rust.

The Role of Inert Gas

An inert gas like Argon is also used during the process. Its purpose is to create a chemically un-reactive atmosphere and to bombard the coating material, dislodging the atoms that will then deposit on the substrate.

Understanding the Trade-offs and Considerations

While powerful, the PVD process has specific requirements and limitations that must be respected for a successful outcome.

The Need for Base Layers

Some substrate materials require a preparatory base layer, often of nickel or chromium, to ensure proper adhesion and enhance resistance to environmental factors.

Material Incompatibility

Certain materials are not suitable for the high-vacuum environment of PVD. For example, brass that has not been galvanized is considered "vacuum-unfriendly" and cannot be reliably coated.

Temperature Sensitivity

Standard PVD processes occur at high temperatures. Substrates like plastics, aluminum, and zinc castings would be damaged under these conditions.

These materials require a specialized Low-Temperature Arc Vapor Deposition (LTAVD) technique to be coated successfully.

Making the Right Choice for Your Goal

Your choice of PVD coating and substrate material should be driven by the primary requirement of your final product.

- If your primary focus is maximum durability and wear resistance: Opt for a titanium-based coating, often combined with nitrogen to form Titanium Nitride, on a strong substrate like stainless steel.

- If your primary focus is a decorative finish with lasting color: A gold PVD coating provides a brilliant and more resilient surface than traditional plating.

- If your primary focus is coating a heat-sensitive material: You must specify a low-temperature PVD process to avoid damaging a substrate like plastic or a zinc casting.

- If your primary focus is extreme corrosion resistance: Using reactive gases to form nitride or oxide coatings provides a superior protective barrier, significantly extending the lifespan of the underlying metal.

Ultimately, the PVD process empowers you to combine the best properties of two different materials—the structure of the substrate and the high-performance surface of the coating.

Summary Table:

| Material Type | Common Examples | Key Function |

|---|---|---|

| Substrate | Stainless Steel, Copper, Aluminum | Base object receiving the coating; provides structural integrity |

| Coating | Titanium, Gold | Vaporized material that imparts surface properties like hardness & color |

| Reactive Gas | Nitrogen, Oxygen | Forms compounds (e.g., Titanium Nitride) for enhanced wear/corrosion resistance |

| Inert Gas | Argon | Creates inert atmosphere & aids in atom dislodgement for deposition |

Ready to select the perfect PVD coating for your project? KINTEK specializes in lab equipment and consumables for advanced coating processes. Whether you need to enhance durability with titanium-based coatings or achieve a brilliant decorative finish with gold, our expertise ensures optimal performance for your laboratory needs. Contact us today to discuss your specific requirements and discover how our solutions can bring your product vision to life!

Visual Guide

Related Products

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Tungsten Evaporation Boat for Thin Film Deposition

People Also Ask

- What are the drawbacks of thermal evaporation? Understanding the Limitations for High-Performance Applications

- What is the vacuum level of a thermal evaporator? Achieve Purity with High Vacuum (10⁻⁵ to 10⁻⁷ Torr)

- What is thermal effect via evaporation? A Simple Guide to Thin-Film Deposition

- What is the process of thermal evaporation in PVD? A Step-by-Step Guide to Thin Film Deposition

- What is the widely used boat made of in thermal evaporation? Choosing the Right Material for High-Purity Deposition