In short, pyrolysis is a highly versatile technology that can process a wide range of plastics, especially those that are difficult or impossible to recycle through traditional mechanical means. This includes post-consumer mixed plastics, materials rejected from recycling facilities, complex multi-layer packaging, and even plastics contaminated with other types like PET and PVC.

The true value of pyrolysis is its ability to handle complex and low-grade plastic waste streams, converting what would otherwise be landfill material into valuable energy products and chemical feedstocks.

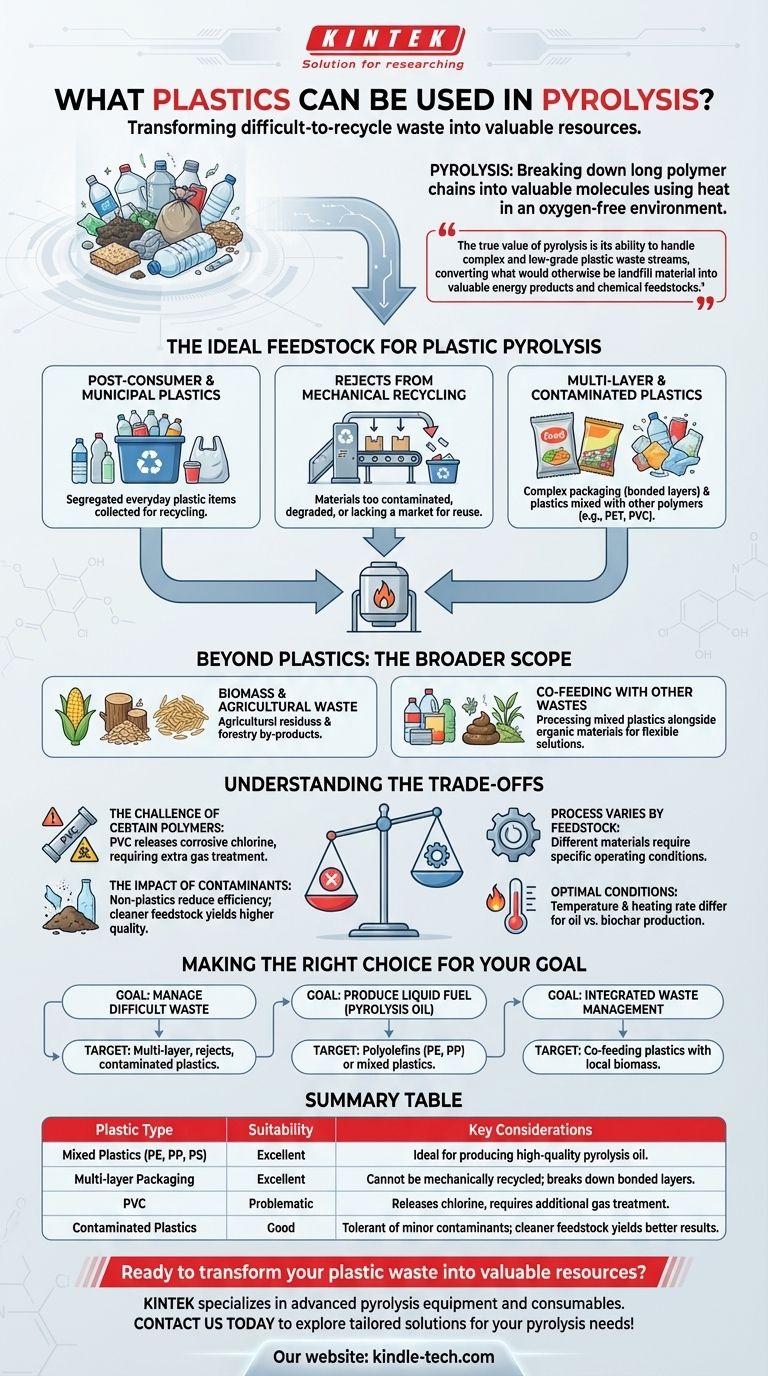

The Ideal Feedstock for Plastic Pyrolysis

Pyrolysis breaks down long polymer chains into smaller, valuable molecules using heat in an oxygen-free environment. This makes it particularly effective for waste streams that confound conventional recycling.

Post-Consumer and Municipal Plastics

A primary source for pyrolysis is post-consumer plastics segregated from municipal solid waste (MSW). These are the everyday plastic items that are collected for recycling.

Rejects from Mechanical Recycling

Pyrolysis is an excellent pathway for materials that fail the mechanical recycling process. These "rejects" may be too contaminated, degraded, or of a type that lacks a market for reuse, making them a perfect feedstock.

Multi-Layer and Contaminated Plastics

The technology excels at processing multi-layer packaging, such as food pouches, which are made of several bonded layers of different materials and cannot be mechanically separated. It can also handle mixed plastics that are contaminated with other polymers, a common challenge in waste management.

Beyond Plastics: The Broader Scope of Pyrolysis

While highly effective for plastics, it's important to understand that pyrolysis is a broader thermal conversion technology applicable to many organic materials.

Biomass and Agricultural Waste

Pyrolysis plants are widely used to process various types of biomass. This includes agricultural residues like corn stalks and rice husks, as well as forestry by-products like wood chips, sawdust, and tree bark.

Co-feeding with Other Wastes

There is growing interest in co-feeding processes, where mixed plastics are processed alongside other organic materials. This can include animal wastes, sewage sludge, or biomass, creating a flexible and robust waste management solution.

Understanding the Trade-offs

While powerful, the process is not without its complexities. The specific composition of the plastic feedstock directly influences the efficiency of the process and the quality of the end products.

The Challenge of Certain Polymers

Some plastics, like Polyvinyl Chloride (PVC), can be problematic. When heated, PVC releases chlorine, which can form corrosive hydrochloric acid, potentially damaging equipment and requiring additional gas treatment steps.

The Impact of Contaminants

Non-plastic contaminants like dirt, glass, or metal can reduce the efficiency of the process. While pyrolysis is tolerant, cleaner feedstock generally yields higher-quality oils and char with less post-processing required.

Process Varies by Feedstock

Different materials require different operating conditions. For example, the optimal temperature and heating rate for converting mixed plastics into oil will differ from the conditions used to convert biomass into biochar, a solid carbon-rich product.

Making the Right Choice for Your Goal

The ideal feedstock depends entirely on your primary objective.

- If your primary focus is managing difficult-to-recycle waste: Target multi-layer packaging, recycling rejects, and contaminated post-consumer plastics.

- If your primary focus is producing liquid fuel (pyrolysis oil): A feedstock rich in polyolefins (like Polyethylene and Polypropylene) is ideal, though mixed plastics are highly effective.

- If your primary focus is integrated waste management: Explore co-feeding plastics with locally available biomass or agricultural residues to maximize resource recovery.

Ultimately, pyrolysis offers a powerful chemical recycling pathway for transforming low-value plastic waste into a valuable resource.

Summary Table:

| Plastic Type | Suitability for Pyrolysis | Key Considerations |

|---|---|---|

| Mixed Plastics (PE, PP, PS) | Excellent | Ideal for producing high-quality pyrolysis oil. |

| Multi-layer Packaging | Excellent | Cannot be mechanically recycled; pyrolysis breaks down bonded layers. |

| PVC | Problematic | Releases chlorine, requires additional gas treatment to avoid corrosion. |

| Contaminated Plastics | Good | Tolerant of minor contaminants, but cleaner feedstock yields better results. |

Ready to transform your plastic waste into valuable resources? KINTEK specializes in advanced pyrolysis equipment and consumables, helping laboratories and waste management facilities efficiently convert complex plastic streams into fuel, chemicals, and feedstocks. Contact us today to explore tailored solutions for your pyrolysis needs!

Visual Guide

Related Products

- FS Electrochemical Hydrogen Fuel Cells for Diverse Applications

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- 1700℃ Muffle Oven Furnace for Laboratory

- Graphite Vacuum Continuous Graphitization Furnace

- Automatic Laboratory Heat Press Machine

People Also Ask

- What are the dimensions for thin-layer spectroelectrochemical cells? Optimize Your Lab's Optical Path Length

- What structural advantages do PEM electrolyzers offer? Compact, High-Density Hydrogen Production Solutions

- What materials are used for the body of a super-sealed electrolytic cell and what are their properties? Select the Right Material for Your Experiment

- What is the significance of using high-purity, corrosion-resistant electrolytic cells? Ensure Quality PEO Coatings

- What is the function of an H-type exchangeable membrane electrolytic cell? Master Precise Reaction Control