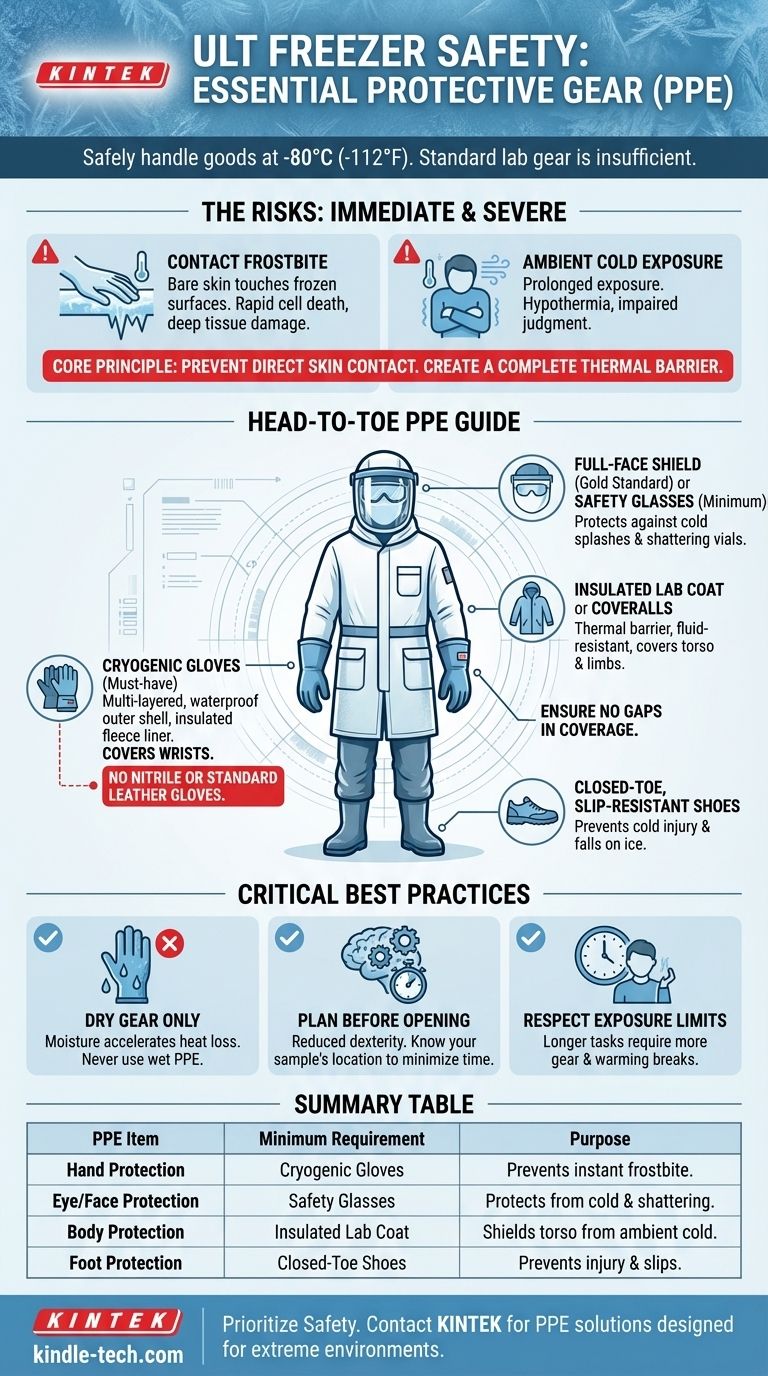

To safely handle goods inside ultra-low temperature (ULT) freezers, you must wear specialized personal protective equipment (PPE) designed for extreme cold. This includes multi-layered cryogenic gloves, an insulated lab coat or coveralls, and full-coverage eye and face protection. Standard laboratory gear is insufficient and will not protect you from the severe and immediate risk of frostbite.

The core principle is preventing direct skin contact with the extreme cold, which can cause severe tissue damage within seconds. Your goal is to create a complete thermal barrier from head to toe using insulated, moisture-resistant equipment.

The Risks of Working with ULT Freezers

An ultra-low temperature (ULT) freezer operates at temperatures around -80°C (-112°F). Exposure to this level of cold, even for a moment, poses significant and immediate danger to personnel.

The Primary Hazard: Contact Frostbite

The most common injury is contact frostbite. This occurs when bare skin touches a frozen surface, such as a sample rack, box, or the interior wall of the freezer.

At these temperatures, the moisture on your skin freezes almost instantly, causing rapid cell death and deep tissue damage.

The Secondary Hazard: Ambient Cold Exposure

Spending more than a few moments organizing samples or taking inventory exposes your entire body to the ambient cold air.

This can lead to more widespread cold-related injuries, hypothermia, and impaired judgment or motor skills, increasing the risk of other accidents.

A Head-to-Toe Guide to Essential PPE

Standard lab coats and nitrile gloves offer no protection from cryogenic temperatures. You must use gear specifically designed for this environment.

Hand Protection: Your First Line of Defense

Your hands are most likely to make direct contact with frozen materials. The absolute minimum requirement is a pair of cryogenic gloves.

These gloves are constructed with multiple layers: an inner insulating fleece or felt layer and a waterproof or water-resistant outer shell. They are often long enough to cover the wrist and part of the forearm.

While heavy leather gloves may offer minimal, short-term protection for handling an item outside the freezer, they are not a substitute for proper cryogenic gloves when reaching inside.

Body and Core Protection

To protect your torso and limbs, an insulated, knee-length lab coat or full-body coveralls are necessary. A standard cotton lab coat provides no meaningful insulation.

Look for materials that are both insulating and fluid-resistant. This protects you from the ambient cold and potential splashes if a frozen vial shatters.

Eye and Face Protection

A full-face shield is the gold standard for protecting against cold splashes and preventing accidental contact between a cold glove and your face.

At a minimum, safety glasses with side shields must be worn. The extreme cold can cause plastic vials to become brittle and shatter upon handling, creating dangerous projectiles.

Footwear and Leg Protection

Your feet must be protected. Wear closed-toe shoes, preferably with slip-resistant soles to handle potential ice build-up near the freezer.

For any task requiring more than a brief door opening, your pants should be made of a sturdy material, and your cryo-gloves and lab coat should overlap to ensure there are no gaps in coverage.

Common Pitfalls and Best Practices

Simply wearing the gear is not enough. How you use it and the protocols you follow are just as critical for safety.

The Danger of Wet or Damp Gear

Moisture is the enemy of insulation. If your gloves or clothing become wet, they lose their protective properties and can actually accelerate heat loss, dramatically increasing the risk of frostbite.

Always ensure your PPE is completely dry before use. If you feel your hands sweating, take a break to dry them and the inside of your gloves.

Dexterity vs. Protection

Cryogenic gloves are bulky and significantly reduce dexterity. This is an unavoidable trade-off for safety.

Plan your work before you open the freezer. Know exactly which box you need to retrieve so you can work efficiently and minimize the time your hands are inside the unit. Do not attempt fine motor tasks with bulky gloves.

Forgetting Exposure Time Limits

The type and duration of the task dictate the level of PPE required. Opening the door for five seconds to grab a single box is very different from a 15-minute inventory session.

Establish clear protocols based on task duration. For longer tasks, more comprehensive coverage and periodic warming breaks are essential.

Making the Right Choice for Your Task

Use the nature of your work to determine the appropriate level of protection.

- If your primary focus is briefly retrieving a known sample: At a minimum, wear cryogenic gloves and safety glasses. Ensure the gloves cover your wrists.

- If your primary focus is organizing, inventorying, or servicing the freezer: You require full protection, including a face shield, an insulated coat, and attention to complete skin coverage.

- If your primary focus is creating a safety protocol for your lab: Mandate a risk assessment for every task, specifying PPE requirements based on duration, with cryogenic gloves and eye protection as the non-negotiable minimum.

Always prioritize your safety over the speed of completing a task.

Summary Table:

| PPE Item | Minimum Requirement | Purpose |

|---|---|---|

| Hand Protection | Cryogenic Gloves | Prevents instant frostbite from contact with frozen surfaces. |

| Eye/Face Protection | Full-Face Shield or Safety Glasses | Protects from cold air and shattering brittle vials. |

| Body Protection | Insulated Lab Coat or Coveralls | Shields torso and limbs from ambient cold exposure. |

| Foot Protection | Closed-Toe, Slip-Resistant Shoes | Prevents injury from cold and potential ice buildup. |

Ensure your lab operates safely at ultra-low temperatures. The right protective gear is not just a recommendation—it's a necessity to prevent severe injury. KINTEK specializes in providing reliable lab equipment and consumables, including safety gear designed for extreme environments. Don't compromise on safety. Contact our experts today to find the right PPE solutions for your ultra-freezer workflows and protect your team.

Visual Guide

Related Products

- 58L Precision Laboratory Ultra Low Temperature Upright Freezer for Critical Sample Storage

- 708L Ultra Low Temperature Freezer High Performance Laboratory Freezer

- 208L Advanced Precision Laboratory Ultra Low Temperature Freezer for Cold Storage

- 608L Essential Laboratory Ultra Low Temperature Freezer For Critical Sample Preservation

- 808L Precision Laboratory Vertical Ultra Low Temperature Freezer

People Also Ask

- How does fast temperature recovery benefit ultra-low freezers? Protect Sample Integrity and Lab Efficiency

- What temperature ranges are typically associated with ultra-low temperature freezers? Preserve Samples from -40°C to -86°C

- What are the recommendations for storing mRNA vaccines in ultra-low temperature freezers? Ensure Absolute Stability at -80°C

- What are ultra-low temperature freezers designed for? Preserving Your Most Valuable Biological Samples

- What are the key features to look for in an ultra-low temperature freezer for mRNA vaccine storage? Essential Features for Absolute Vaccine Integrity