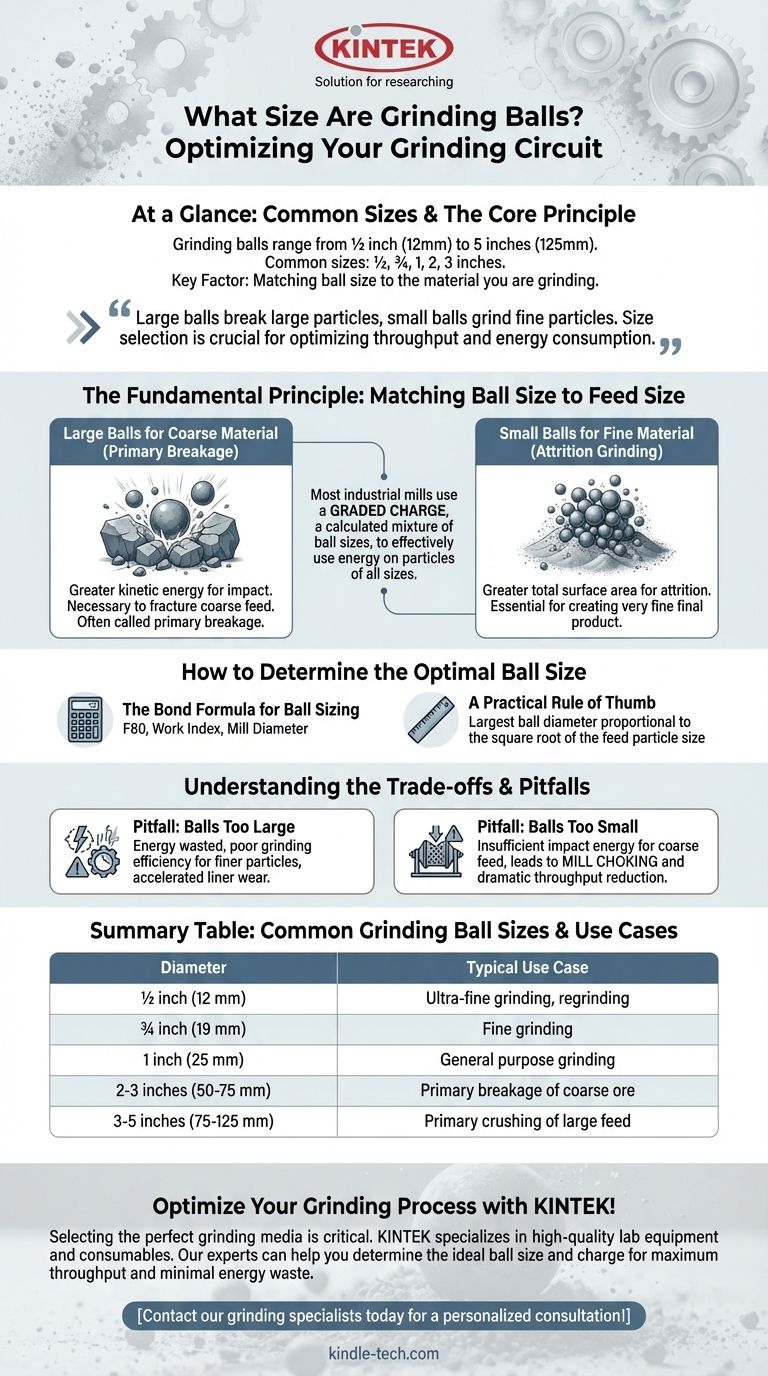

At a glance, grinding balls are typically available in diameters ranging from as small as ½ inch (about 12 mm) to as large as 5 inches (about 125 mm). Common sizes include ½, ¾, 1, 2, and 3-inch balls, with the specific size being one of the most critical factors in the efficiency of a ball mill grinding circuit.

The core principle is not about finding a single "correct" size, but about matching the ball size to the material you are grinding. Large balls break large particles, and small balls grind fine particles, making size selection a crucial decision for optimizing throughput and energy consumption.

The Fundamental Principle: Matching Ball Size to Feed Size

The entire purpose of a ball mill is to reduce the size of particles through impact and attrition. The size of the grinding media (the balls) directly dictates how this energy is applied.

Large Balls for Coarse Material

Large, heavy balls possess greater kinetic energy upon impact. This high-impact energy is necessary to fracture large, coarse feed particles effectively.

This is often called primary breakage. Without balls large enough to break the biggest particles entering the mill, the entire process will halt.

Small Balls for Fine Material

Conversely, smaller balls have a significantly greater total surface area for a given weight or volume. A tonne of 1-inch balls has far more contact points than a tonne of 3-inch balls.

This vast surface area is essential for attrition grinding, where fine particles are rubbed and worn down into even finer powders. Small balls are efficient at creating a very fine final product but lack the impact force to break large rocks.

The Concept of a Graded Charge

Most industrial mills do not use a single, uniform ball size. They use a graded charge, which is a carefully calculated mixture of different ball sizes.

As material breaks down inside the mill, it requires progressively smaller balls to continue grinding it efficiently. A graded charge ensures that energy is used effectively on particles of all sizes within the mill.

How to Determine the Optimal Ball Size

While visual inspection provides a starting point, engineers use established methods to calculate the ideal ball size for a given operation.

The Bond Formula for Ball Sizing

The industry standard for this calculation is an empirical formula developed by Fred Bond. It is the most reliable method for determining the optimal ball diameter.

The formula primarily considers three key variables:

- Feed Size (F80): The mesh size that 80% of the feed material passes through.

- Material Hardness (Work Index): A measure of the energy required to grind a specific ore.

- Mill Diameter: The internal diameter of the mill shell.

A Practical Rule of Thumb

A widely used simplification suggests the largest ball's diameter should be proportional to the square root of the feed particle size.

This ensures the largest media has enough impact energy to break the largest feed particles. The rest of the charge is then graded downward from this calculated top size.

Understanding the Trade-offs

Selecting the wrong ball size has significant consequences for both performance and cost.

Pitfall: Using Balls That Are Too Large

If the balls are too large for the feed material, energy is wasted. The immense impact force is not required, and the low total surface area of the balls results in poor grinding efficiency for finer particles. This also accelerates the wear on the mill's steel liners.

Pitfall: Using Balls That Are Too Small

This is often the more severe problem. If the balls are too small, they will not have enough impact energy to break the coarsest feed particles.

This leads to a buildup of hard-to-grind material in the mill, a dramatic reduction in throughput, and a situation known as mill choking.

Making the Right Choice for Your Goal

The optimal grinding media charge is always a function of your specific objective.

- If your primary focus is primary crushing of coarse ore: You must use large-diameter balls (e.g., 3-5 inches) as the top size to provide the necessary impact energy.

- If your primary focus is ultra-fine grinding or regrinding: A charge of smaller balls (e.g., ½-1 inch) is required to maximize surface area and promote efficient attrition.

- If your primary focus is all-purpose grinding with a wide feed distribution: A graded charge with a scientifically calculated mix of large, medium, and small balls will deliver the most efficient and balanced performance.

Choosing the correct grinding ball size is the single most important lever for optimizing the performance and energy efficiency of your grinding circuit.

Summary Table:

| Common Grinding Ball Sizes (Diameter) | Typical Use Case |

|---|---|

| ½ inch (12 mm) | Ultra-fine grinding, regrinding |

| ¾ inch (19 mm) | Fine grinding |

| 1 inch (25 mm) | General purpose grinding |

| 2-3 inches (50-75 mm) | Primary breakage of coarse ore |

| 3-5 inches (75-125 mm) | Primary crushing of large feed |

Optimize your grinding process with KINTEK!

Selecting the perfect grinding media is critical for your lab's efficiency and cost-effectiveness. KINTEK specializes in high-quality lab equipment and consumables, including a full range of grinding balls and milling solutions. Our experts can help you determine the ideal ball size and charge for your specific material and application, ensuring maximum throughput and minimal energy waste.

Contact our grinding specialists today for a personalized consultation and see the KINTEK difference in your results!

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- Why are tungsten carbide grinding jars and balls preferred for high-purity lithium ceramic powders? Ensure Peak Purity.

- Why is a ball mill jar lined with Y-ZrO2 required for Na3PS4 synthesis? Ensuring Purity in Sulfide Electrolytes

- What is the benefit of using tungsten carbide (WC) milling jars and balls? Achieve High-Energy Milling Efficiency

- Why are excellent sealing and corrosion resistance required for WC-10Co ball milling? Ensure High-Purity Mixing Results

- What is the ball mill based on the principle of? Impact and Attrition for Efficient Grinding