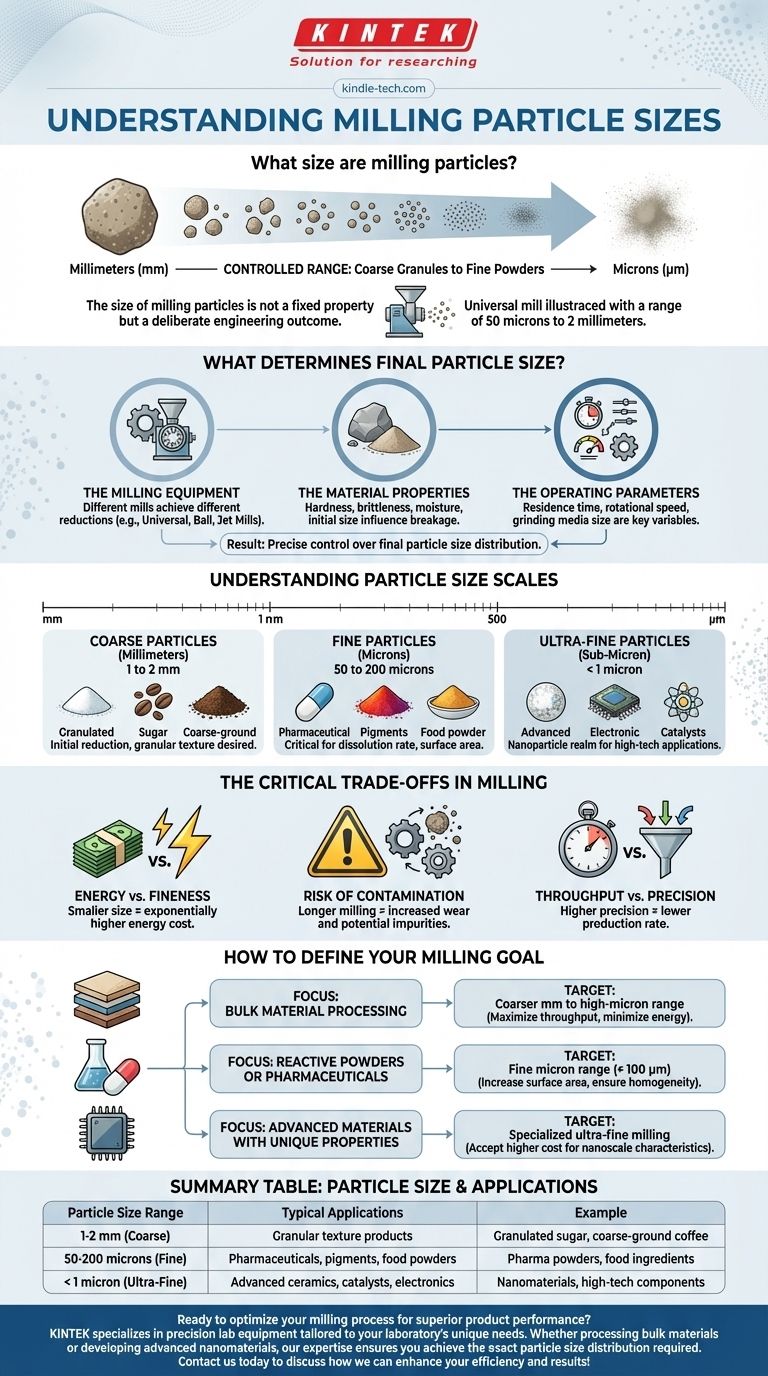

In industrial milling, the final particle size of a ground material is not a single number but a carefully controlled range. Depending on the equipment and application, milled particles can span from coarse granules measured in millimeters down to fine powders measured in microns. For example, a universal mill can be configured to produce particles ranging from 50 microns to 2 millimeters.

The size of milling particles is not a fixed property but a deliberate engineering outcome. It is determined by the choice of milling technology and operating parameters, all tailored to the specific requirements of the final product.

What Determines Final Particle Size?

The final size of a milled particle is the result of three interacting factors: the equipment used, the properties of the material being milled, and the specific parameters of the operation.

The Milling Equipment

Different types of mills are designed to achieve different levels of size reduction. A universal mill, for example, uses rotating and stationary elements to grind material within a specific range.

Other equipment, like a ball mill, tumbles grinding media to crush particles, while a jet mill uses high-velocity air to cause particles to collide and fracture, often achieving much finer sizes.

The Material Properties

The inherent characteristics of the starting material (the "mill feed") are critical. Hard, brittle materials will fracture differently than soft, ductile ones.

Factors like moisture content, abrasiveness, and initial particle size all influence how easily the material can be broken down and how much energy will be required.

The Operating Parameters

Operators can fine-tune the process to control the output. Key variables include the residence time (how long the material stays in the mill), the rotational speed of the equipment, and the type and size of the grinding media used.

Adjusting these parameters allows for precise control over the final particle size distribution.

Understanding Particle Size Scales

To understand the specifications, it's helpful to visualize the different scales and their common applications.

Coarse Particles (Millimeters)

This range, typically from 1 to 2 mm, is common for initial size reduction or for products where a granular texture is desired. Think of coarse-ground coffee or granulated sugar.

Fine Particles (Microns)

The micron range (1 micron = 0.001 mm) is where most industrial powders lie. A particle size of 50 to 200 microns is common for applications like pharmaceuticals, pigments, and food powders where properties like dissolution rate and surface area are critical.

Ultra-Fine Particles (Sub-Micron)

Specialized milling processes can produce particles smaller than 1 micron, entering the "nanoparticle" realm. These are used in high-technology applications like advanced ceramics, catalysts, and electronics where unique material properties emerge at the nanoscale.

The Critical Trade-offs in Milling

Achieving a specific particle size is never without its trade-offs. Understanding these limitations is key to an efficient and effective process.

Energy vs. Fineness

There is a fundamental relationship between energy input and particle size. Grinding a material from 1 mm to 100 microns requires significantly more energy than the initial coarse grinding. Achieving smaller particle sizes is exponentially more expensive.

Throughput vs. Precision

Milling to a very specific and narrow particle size distribution often requires longer processing times or more complex classification steps. This can reduce the overall production rate (throughput) of the system.

Risk of Contamination

Longer and more intense milling increases the wear and tear on the mill's internal components and grinding media. This raises the risk of introducing small amounts of contaminants from the equipment into the final product, a critical concern in high-purity applications.

How to Define Your Milling Goal

The "correct" particle size is entirely dependent on your objective. Use these guidelines to frame your requirements.

- If your primary focus is bulk material processing: You will likely operate in the coarser millimeter-to-high-micron range to maximize throughput and minimize energy costs.

- If your primary focus is creating reactive powders or pharmaceuticals: Your target will be the fine micron range (e.g., below 100 µm) to increase surface area and ensure homogeneity.

- If your primary focus is advanced materials with unique properties: You may require specialized ultra-fine milling, accepting the higher cost and complexity to achieve specific nanoscale characteristics.

Ultimately, the ideal particle size is the one that precisely meets the performance and economic requirements of your application.

Summary Table:

| Particle Size Range | Typical Applications |

|---|---|

| 1-2 mm (Coarse) | Granulated sugar, coarse-ground coffee |

| 50-200 microns (Fine) | Pharmaceuticals, pigments, food powders |

| <1 micron (Ultra-Fine) | Advanced ceramics, catalysts, electronics |

Ready to optimize your milling process for superior product performance? KINTEK specializes in precision lab equipment and consumables tailored to your laboratory's unique needs. Whether you're processing bulk materials or developing advanced nanomaterials, our expertise ensures you achieve the exact particle size distribution required. Contact us today to discuss how we can enhance your efficiency and results!

Visual Guide

Related Products

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Single Horizontal Jar Mill

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Jar Mill with Agate Grinding Jar and Balls

People Also Ask

- How does the argon atmosphere protection in a ball mill affect the final quality of CuCr50 alloy powder? Explained

- Why is grinding equipment used for sulfur-carbon solid-state battery cathodes? Achieve Peak Conductivity

- What is the primary function of a laboratory ball mill in Rice Husk Ash (RHA) modification? Achieve Peak Densification

- What is the primary function of mechanical grinding in 2G biomass pretreatment? Unlock High-Yield Conversion

- Why are 3mm zirconia grinding balls selected for Na3FePO4CO3 synthesis? Optimize Energy and Purity

- What is the primary function of a ball mill in calcium thermal reduction? Optimize Your Raw Material Preparation

- Can I use wet grinder for dry grinding? Avoid Damaging Your Kitchen Appliance

- What are laboratory mixers used for? Achieve Perfect Sample Homogeneity and Reliable Results