In practice, test sieves come in several standard frame diameters, most commonly 8 inches (200 mm) and 12 inches (300 mm). These frames hold a woven wire mesh or perforated plate with openings ranging from several millimeters down to as fine as 25 microns, allowing for precise particle size separation.

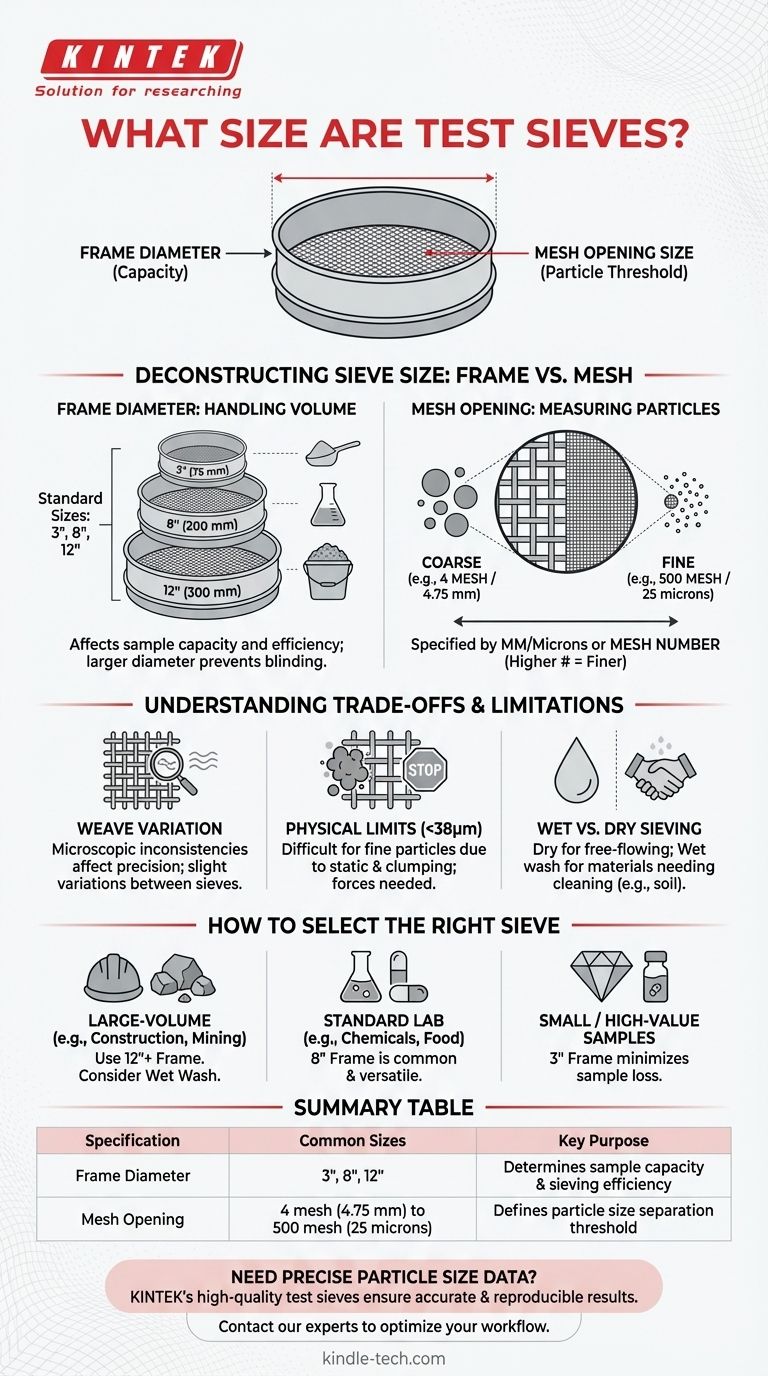

The "size" of a test sieve is not a single number but a combination of two critical specifications: the frame diameter, which dictates sample capacity, and the mesh opening size, which determines the particle size you are measuring.

Deconstructing Sieve Size: Frame vs. Mesh

To select the correct sieve, you must understand its two primary measurements and how they relate to your specific material and analysis goals.

Frame Diameter: Handling Your Sample Volume

The frame is the circular metal body of the sieve. Its diameter determines the surface area available for sieving and, therefore, how much material you can process at one time.

Common frame diameters include 3" (75 mm), 8" (200 mm), and 12" (300 mm). While larger sizes like 18" or 24" exist, the 8-inch and 12-inch versions are the workhorses of most laboratories.

A larger diameter prevents the sample from "blinding" the mesh (clogging the openings) and ensures each particle has a chance to pass through, leading to a more accurate and efficient separation.

Mesh Opening: Measuring Your Particles

The mesh is the screen at the bottom of the frame. Its size defines the threshold for particle separation.

This is specified either by the direct opening size (e.g., in millimeters or microns) or by a mesh number. The mesh number indicates the number of openings per linear inch; a higher number means smaller, finer openings.

For example, a 4 mesh sieve has a large opening of about 4.75 mm, while a 500 mesh sieve has a very fine opening of just 0.025 mm, or 25 microns.

Understanding the Trade-offs and Limitations

While test sieves are a fundamental tool, they are not without their operational constraints. Understanding these is key to producing reliable data.

Weave Variation and Reproducibility

The woven wire mesh, by its nature, has slight variations. These microscopic inconsistencies in the weave can affect the exact size and shape of the openings.

For highly precise or regulated industries, this means test results may have slight variations from one sieve to another, even if they share the same nominal size. This must be accounted for in data analysis.

The Physical Limits of Sieving

Sieving becomes progressively more difficult as particle size decreases. Forces like static electricity and moisture cause fine particles to clump together and resist passing through the mesh.

The practical lower limit for dry sieving is typically around 38 microns. Below this, a different technique is often required.

Wet vs. Dry Sieving

Dry sieving is the standard method, using shaking or tapping to separate free-flowing powders. It is fast and simple for most materials.

Wet wash sieving is used when water is needed to help particles pass through the screen. This is essential for materials like soil or aggregates, where fine silt and clay are stuck to larger rocks and must be washed off for an accurate measurement.

How to Select the Right Sieve

Your choice depends entirely on your material and the goal of your analysis.

- If your primary focus is large-volume materials (e.g., construction aggregate, mining): Choose a larger frame diameter like 12" (300 mm) or more to handle the sample size and consider wet wash sieves to clean the particles.

- If your primary focus is standard laboratory analysis (e.g., chemicals, food powders, pharmaceuticals): The 8" (200 mm) frame is the most common and versatile standard for a wide range of particle sizes.

- If your primary focus is small or high-value samples: A 3" (75 mm) frame is ideal for minimizing sample loss and is easier to handle for very small quantities.

Choosing the right sieve is the first step toward accurate and repeatable particle size analysis.

Summary Table:

| Specification | Common Sizes | Key Purpose |

|---|---|---|

| Frame Diameter | 3", 8", 12" | Determines sample capacity and sieving efficiency |

| Mesh Opening | 4 mesh (4.75 mm) to 500 mesh (25 microns) | Defines particle size separation threshold |

Need precise particle size data? KINTEK's high-quality test sieves ensure accurate and reproducible results for your laboratory. Whether you work with aggregates, chemicals, pharmaceuticals, or food powders, we provide the right sieve size and mesh for your application. Contact our experts today to optimize your particle analysis workflow!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

People Also Ask

- How do high-precision sieving systems benefit zeolite preparation? Maximize Adsorption for Wastewater Treatment

- Why is a laboratory sieving system required for bentonite in coatings? Ensure Flawless Surface Performance

- Why is a laboratory electromagnetic vibratory sieve shaker used? Optimize Walnut Shell Chemical Pretreatment

- What function does a sieving system perform during HPS powder pretreatment? Ensure Uniform Particle Size Distribution

- Why use a vibratory sieve shaker for PET powder? Achieve Precise Particle Size Control for Chemical Research