In short, there is no single standard size for balls used in ball milling. The optimal ball size is a critical process parameter that is carefully selected based on the size of the milling jar, the initial size of the material you are grinding, and your desired final particle size. The choice is a deliberate balance between impact force and grinding efficiency.

The core principle is that ball size must be proportional to the task. Larger balls provide the high-impact energy needed to break down coarse materials, while smaller balls offer the greater surface area required for producing extremely fine or nano-scale powders.

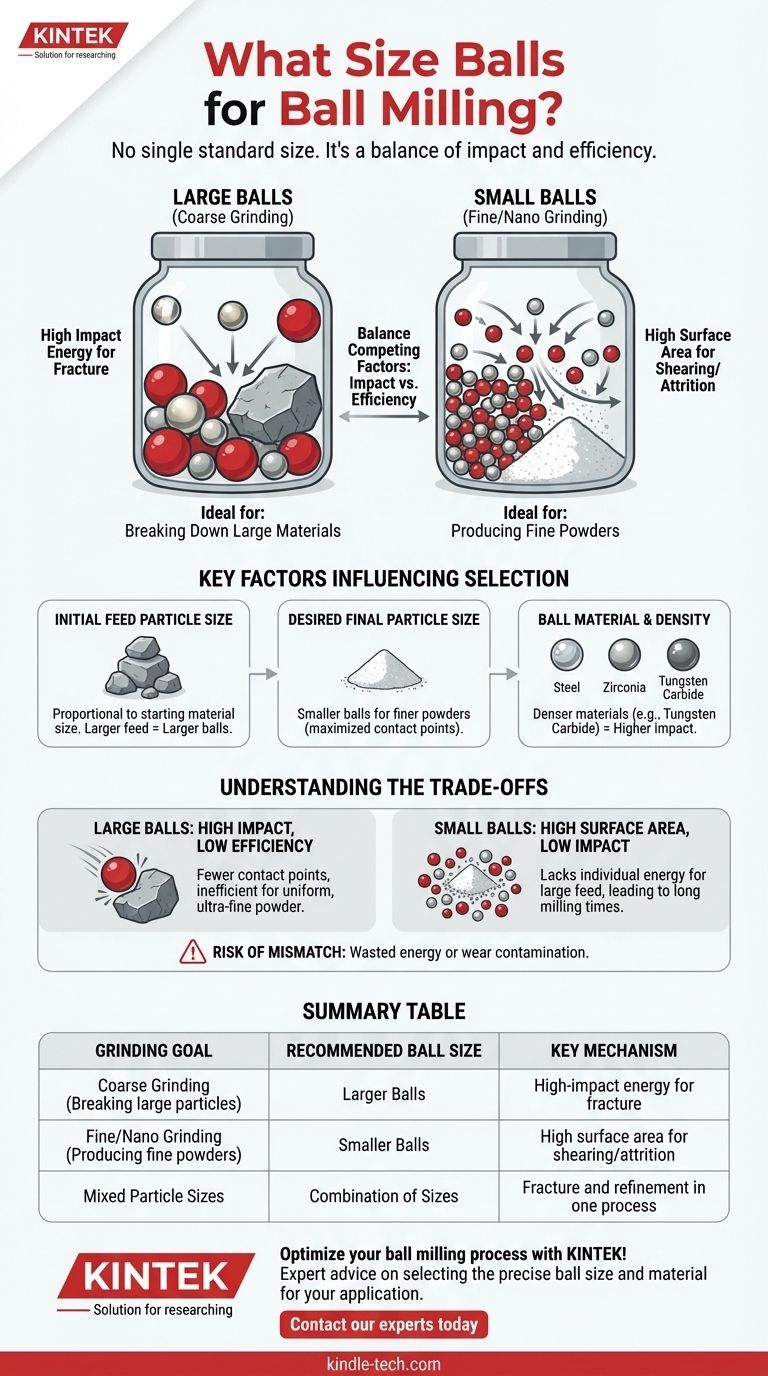

The Core Principle: Matching Ball Size to the Task

Understanding why ball size is a variable is the first step to mastering the milling process. The selection is less about a fixed number and more about the ratios and physics involved in particle size reduction.

Why There's No "Standard" Size

The term "ball milling" covers a vast range of applications, from crushing large mineral ores to producing nano-powders of 2-20 nm. A single ball size could not possibly be effective for this entire spectrum. The choice is always relative to the specific application.

The Role of Jar Size

The grinding jar contains the entire system. The balls need enough empty space to fall and cascade, which generates the impact energy for grinding. If the balls are too large relative to the jar, their movement is restricted, and grinding becomes inefficient.

The Goal: Coarse vs. Fine Grinding

The grinding mechanism itself dictates the ball size. Breaking large particles apart requires high-energy impacts (fracture), which is best delivered by larger, heavier balls. Reducing already small particles into a fine powder relies on attrition and compression (shearing), which is more efficiently achieved with the millions of contact points provided by a large quantity of smaller balls.

Key Factors Influencing Ball Selection

To select the right media, you must consider the starting point, the desired endpoint, and the properties of the balls themselves.

Initial Feed Particle Size

As a rule of thumb, the grinding ball diameter should be proportional to the size of the material you are starting with. Larger feed particles require larger, heavier balls with enough kinetic energy to initiate a crack and break them down.

Desired Final Particle Size

To achieve the fine nano-powders mentioned in research, you need to maximize the number of collision events and the total grinding surface area. A charge of smaller balls provides exponentially more contact points than an equal volume of larger balls, making it ideal for final-stage, fine grinding.

Ball Material and Density

While not a measure of size, the material of the balls (e.g., stainless steel, zirconia, tungsten carbide) is critical. Denser materials provide a much higher impact force for the same size ball, as impact energy is directly related to mass.

Understanding the Trade-offs

Choosing a ball size is always an exercise in balancing competing factors. What makes one size effective for one goal makes it inefficient for another.

Large Balls: High Impact, Low Efficiency

Larger balls excel at coarse grinding. Their high mass generates significant impact energy, but they have far fewer contact points within the mill. This makes them inefficient for producing a uniform, ultra-fine powder.

Small Balls: High Surface Area, Low Impact

A multitude of small balls creates an enormous number of contact points, perfect for attrition and producing fine powders. However, they may lack the individual impact energy to break down a larger feed material, leading to very long or ineffective milling times.

The Risk of a Mismatch

Using balls that are too small for the feed material will result in wasted energy, as the balls will simply bounce off the particles without fracturing them. Conversely, using balls that are too large for producing a fine powder will be inefficient and may introduce unnecessary contamination from wear.

Making the Right Choice for Your Goal

Base your selection on the primary objective of your milling process.

- If your primary focus is breaking down large, coarse material: Opt for larger, heavier grinding balls that can deliver the high impact energy needed for initial fracture.

- If your primary focus is producing very fine or nano-sized powders: Use a large quantity of smaller-diameter balls to maximize the grinding surface area and the number of particle-shearing contact points.

- If you are processing a material with a wide particle size distribution: Consider using a mix of ball sizes, where larger balls break down the coarse fraction and smaller balls refine the resulting particles.

Ultimately, selecting the correct ball size is essential for optimizing your grinding process for speed, efficiency, and the desired final result.

Summary Table:

| Grinding Goal | Recommended Ball Size | Key Mechanism |

|---|---|---|

| Coarse Grinding (Breaking large particles) | Larger Balls | High-impact energy for fracture |

| Fine/Nano Grinding (Producing fine powders) | Smaller Balls | High surface area for shearing/attrition |

| Mixed Particle Sizes | Combination of Sizes | Fracture and refinement in one process |

Optimize your ball milling process with KINTEK!

Selecting the right grinding media is crucial for achieving your target particle size efficiently. Whether you're processing coarse materials or aiming for nano-scale powders, KINTEK's expertise in lab equipment and consumables ensures you get the precise ball size and material for your application.

Contact our experts today to discuss your specific needs and let us help you enhance your grinding efficiency and results.

Visual Guide

Related Products

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

People Also Ask

- What is the factor affecting size reduction? Master Material Properties for Optimal Milling

- What is the function of ultrasonic homogenizers in g-C3N4 preparation? Unlocking Maximum Catalytic Activity

- What is the primary purpose of using grinding tools like agate mortars? Optimize LTO Electrode Performance

- What are the components of a grinding mill? Understand the Core Systems for Efficient Comminution

- How does ball milling equipment influence powder metallurgy? Master Superalloy Preparation & Precision Modeling

- What is the contamination during ball milling? Learn to Control It for Purer Materials

- Why are polyurethane grinding jars and agate grinding balls preferred for milling B4C? Protect Material Purity

- Why are zirconia grinding beads utilized for LLZTO solid-state electrolytes? Ensuring Purity & High Ionic Conductivity