There is no single melting temperature for a crucible. A crucible is a type of container, not a specific material. Its melting point is determined entirely by the material it is made from, which can range from common ceramics to precious metals, each chosen for a specific high-temperature task.

The most important number is not a material's melting point, but its maximum recommended operating temperature. This is always significantly lower than the actual melting point and accounts for factors like structural integrity and chemical stability under heat.

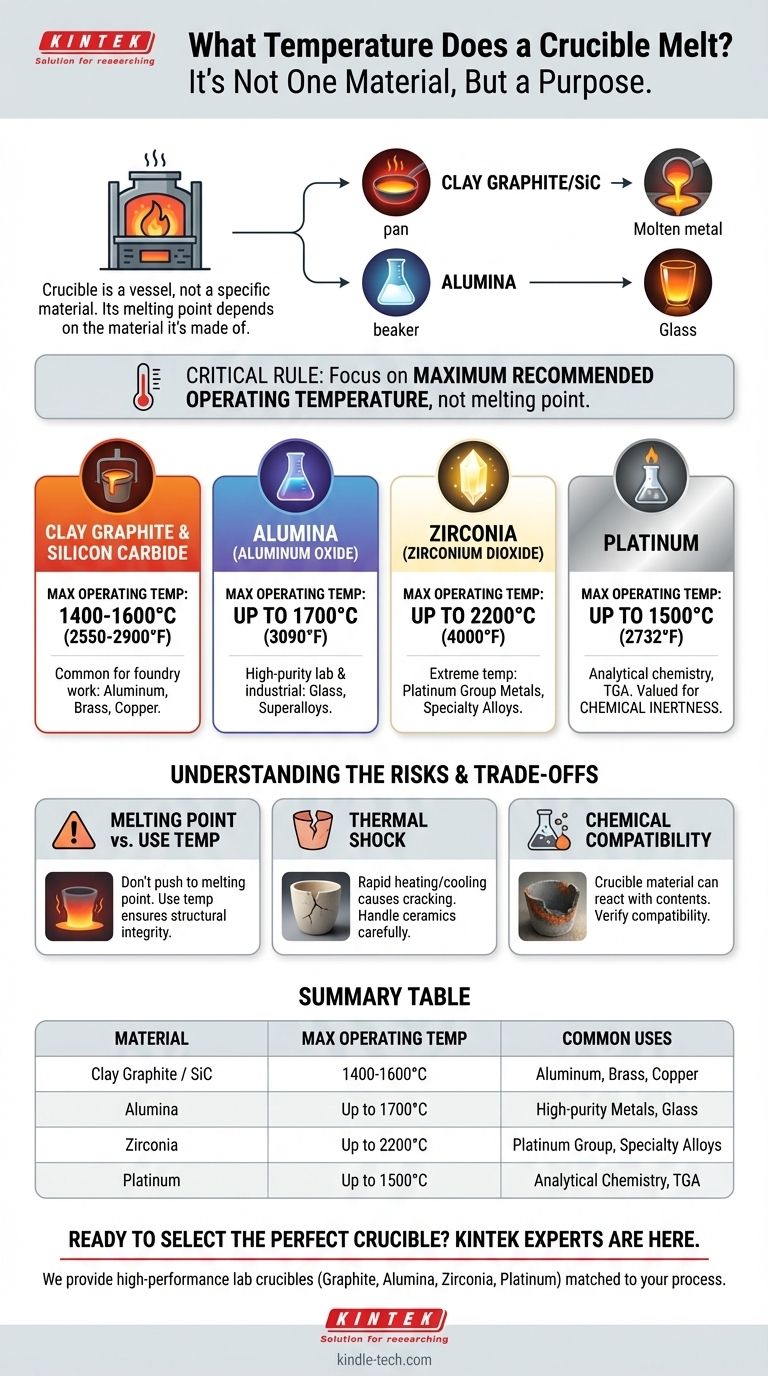

Why a "Crucible" Isn't a Single Material

A crucible is simply a vessel designed to withstand extreme temperatures. Think of it like a "pan" for a furnace. Just as you wouldn't use a non-stick pan to bake a pizza, you wouldn't use a steel crucible to melt platinum.

The material is chosen based on the temperature required, the substance being heated, and the risk of chemical reactions between the container and its contents.

Common Crucible Materials and Their Limits

Each material offers a different balance of temperature resistance, durability, and cost. The temperatures listed are general guidelines; always consult the manufacturer's specifications for your specific product.

Clay Graphite & Silicon Carbide

These are the most common crucibles for foundry work, used for melting non-ferrous metals like aluminum, brass, and copper. They offer excellent thermal conductivity, meaning they transfer heat to the metal efficiently.

Their maximum operating temperatures are typically in the range of 1400-1600°C (2550-2900°F).

Alumina (Aluminum Oxide)

Alumina is a high-purity ceramic crucible used extensively in laboratory and industrial settings for melting glass, high-purity metals, and superalloys. It is chemically stable and has a very high melting point.

While pure alumina melts at 2072°C (3762°F), its practical use temperature is generally limited to around 1700°C (3090°F).

Zirconia (Zirconium Dioxide)

For even more demanding applications, zirconia crucibles offer superior performance. They are used for melting platinum group metals and specialty alloys that require extremely high temperatures and a non-reactive container.

Zirconia crucibles can often be used at temperatures up to 2200°C (4000°F).

Platinum

Platinum crucibles are not chosen for extreme temperature resistance but for their exceptional chemical inertness. They are a standard in analytical chemistry for procedures like thermogravimetric analysis (TGA) and sample preparation.

Platinum's melting point is 1768°C (3215°F), so its use is restricted to temperatures well below this, often under 1500°C (2732°F).

Understanding the Trade-offs and Risks

Selecting a crucible based on melting point alone is a common and dangerous mistake. You must consider the practical limitations of the material.

Melting Point vs. Use Temperature

A material begins to soften, creep, and lose its structural strength long before it melts. Pushing a crucible to its melting point will cause it to deform or fail, spilling molten material. The maximum operating temperature is the safe upper limit provided by the manufacturer.

The Danger of Thermal Shock

Ceramic crucibles (like alumina and zirconia) are brittle. Heating or cooling them too quickly creates internal stress that will cause them to crack or shatter. This failure, known as thermal shock, can happen at any temperature and is a primary cause of crucible destruction.

Chemical Compatibility is Crucial

The material you are melting can chemically attack the crucible itself. For example, certain fluxes or highly reactive metals can corrode a crucible wall, causing it to fail at a temperature far below its theoretical limit. Always verify that your crucible material is compatible with the substance you are heating.

How to Select the Right Crucible

Match the crucible material to the specific demands of your work.

- If your primary focus is melting common metals like aluminum, copper, or brass: A clay graphite or silicon carbide crucible provides the best balance of performance and cost.

- If your primary focus is high-purity lab work or melting steel and superalloys: An alumina crucible is the standard, with zirconia reserved for even higher temperature requirements.

- If your primary focus is precise analytical chemistry or working with aggressive chemicals: A platinum crucible is required for its chemical inertness, not its heat tolerance.

- If your primary focus is hobby casting of low-temperature metals like lead or zinc: A simple and inexpensive cast iron or steel pot is often sufficient.

Ultimately, choosing the right crucible is about matching the material's properties to the unique demands of your process.

Summary Table:

| Crucible Material | Maximum Operating Temperature | Common Uses |

|---|---|---|

| Clay Graphite / Silicon Carbide | 1400-1600°C (2550-2900°F) | Aluminum, brass, copper foundry work |

| Alumina (Aluminum Oxide) | Up to 1700°C (3090°F) | High-purity metals, glass, superalloys |

| Zirconia (Zirconium Dioxide) | Up to 2200°C (4000°F) | Platinum group metals, specialty alloys |

| Platinum | Up to 1500°C (2732°F) | Analytical chemistry, TGA, chemical inertness |

Ready to select the perfect crucible for your high-temperature application?

At KINTEK, we specialize in providing high-performance lab equipment and consumables, including crucibles made from graphite, alumina, zirconia, and platinum. Our experts will help you match the right material to your specific process requirements, ensuring safety, efficiency, and optimal results.

Don't risk crucible failure—contact our team today for personalized guidance and a quote tailored to your laboratory needs!

Visual Guide

Related Products

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- High Purity Pure Graphite Crucible for Evaporation

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

- High Purity Pure Graphite Crucible for Electron Beam Evaporation

People Also Ask

- What are the benefits of using an alumina crucible with a lid for TiB2 nanopowder heat treatment? Ensure High Purity

- What is a crucible material for a furnace? A Guide to Choosing the Right High-Temperature Container

- What precautions should be taken when using a crucible? Essential Steps for Safety and Accuracy

- What temperature can alumina crucible withstand? A Guide to High-Temperature Stability and Safety

- How much heat can a ceramic crucible withstand? A Guide to Material-Specific Temperature Limits