To be precise, quartz glass does not have a sharp melting point like a crystalline solid such as ice. Instead, it progressively softens over a wide range of temperatures. Its official softening point is approximately 1665°C (3029°F), which is the temperature at which it begins to deform under its own weight.

The concept of a single "melting point" for quartz glass is misleading. The key is understanding its viscosity—it doesn't melt, it softens. Its practical, continuous-use temperature is significantly lower than its softening point, typically around 1100°C (2012°F), to avoid structural failure.

Why Quartz Glass Doesn't "Melt"

Understanding why quartz behaves this way is critical for anyone using it in high-temperature applications. The distinction lies in its internal structure.

The Amorphous vs. Crystalline Difference

Crystalline solids, like natural quartz crystals, have atoms arranged in a highly ordered, repeating lattice. When heated, the bonds in this lattice break at a specific temperature, causing a sudden transition from solid to liquid—a true melting point.

Quartz glass, also known as fused silica, is amorphous. Its silicon and oxygen atoms are arranged randomly, much like a liquid. Because there is no ordered lattice to break, it simply becomes less viscous (more fluid) as temperature increases.

Thinking in Terms of Viscosity

The most accurate way to think about the thermal properties of glass is not melting, but viscosity. Imagine viscosity as a material's resistance to flow.

Cold honey is highly viscous and barely flows. Hot honey is much less viscous and flows easily. Quartz glass behaves similarly, but on a much higher temperature scale. As it heats up, its viscosity drops, and it gradually transitions from a hard solid to a thick, taffy-like substance, and finally to a fluid.

Key Thermal Benchmarks of Quartz Glass

Engineers and scientists use several standard temperature points to define the working characteristics of quartz glass.

Strain Point: ~1070°C (1958°F)

This is the temperature at which internal stresses can be relieved in several hours. For practical purposes, it can be considered the absolute maximum temperature for long-term use without risking stress-induced failure.

Annealing Point: ~1140°C (2084°F)

At this temperature, internal stresses can be relieved in a matter of minutes. This is often cited as the maximum continuous service temperature. Operating above this point for extended periods will lead to deformation and sagging.

Softening Point: ~1665°C (3029°F)

This is the temperature most people are asking about when they say "melting point." At this point, the glass is soft enough that it will begin to deform under its own weight. It is a material limit, not a safe operating temperature.

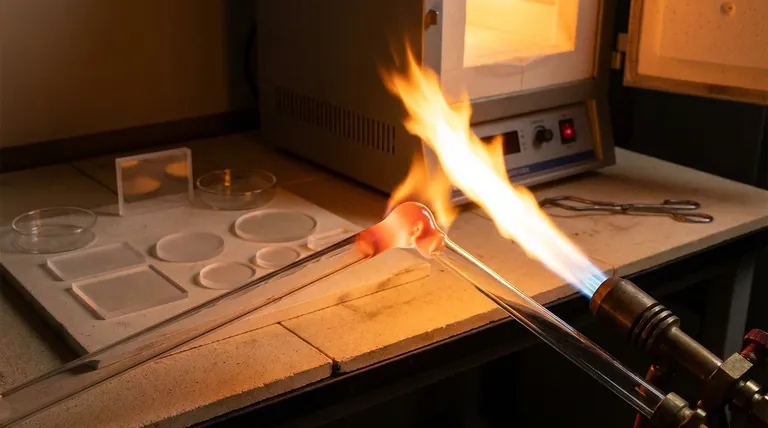

Working Point: ~2000°C (3632°F)

At this temperature, the viscosity of quartz glass is low enough for it to be manipulated, shaped, and welded in processes like glassblowing or fiber optic manufacturing.

Understanding the Trade-offs and Practical Limits

Using the softening point as a design temperature is a common and costly mistake. Understanding the practical limitations is essential for success.

Continuous Service Temperature is Critical

The most important takeaway is that the maximum continuous service temperature (~1100°C) is far below the softening point (~1665°C). A furnace tube made of quartz, for example, will sag and fail if operated at 1500°C, even though that is below its softening point.

The Risk of Devitrification

When held at high temperatures (especially above 1100°C) for extended periods, quartz glass can begin to devitrify. This means the amorphous structure starts to reorganize into a crystalline form (cristobalite).

Devitrification makes the glass opaque and, more importantly, extremely brittle and mechanically weak. This process is irreversible and leads to component failure.

Exceptional Thermal Shock Resistance

One of the primary benefits of quartz is its extremely low coefficient of thermal expansion. This means it barely expands or contracts when heated or cooled.

This property gives it incredible resistance to thermal shock. You can heat a quartz tube to red-hot and plunge it into cold water without it shattering—a feat that would instantly destroy ordinary glass.

Making the Right Choice for Your Application

Your application dictates which thermal property matters most.

- If your primary focus is long-term, high-temperature stability (e.g., furnace tubes, process chambers): Design your system to operate below the continuous service limit of approximately 1100°C to prevent deformation and devitrification.

- If your primary focus is rapid thermal processing (e.g., lampworking, semiconductor wafer processing): You can utilize the material's properties up to its working point, but be mindful of the processing time to avoid devitrification.

- If your primary focus is thermal shock resistance (e.g., lab beakers, optical viewports): Quartz is an exceptional choice due to its near-zero thermal expansion, but you must still respect its maximum continuous service temperature for mechanical integrity.

Understanding these thermal benchmarks empowers you to leverage the unique properties of quartz glass without risking material failure.

Summary Table:

| Thermal Point | Temperature | Significance |

|---|---|---|

| Strain Point | ~1070°C (1958°F) | Maximum temperature for long-term use without stress failure. |

| Annealing Point | ~1140°C (2084°F) | Maximum continuous service temperature; stress is relieved in minutes. |

| Softening Point | ~1665°C (3029°F) | Begins to deform under its own weight; not a safe operating temperature. |

| Working Point | ~2000°C (3632°F) | Viscosity is low enough for shaping and welding. |

Need a reliable solution for your high-temperature applications?

At KINTEK, we specialize in high-purity lab equipment, including quartz glass components designed for exceptional thermal stability and shock resistance. Our experts can help you select the right materials to ensure your processes run safely and efficiently, avoiding costly failures like devitrification or deformation.

Contact our team today to discuss your specific laboratory needs and discover how our products can enhance your operations.

Visual Guide

Related Products

- High Temperature Resistant Optical Quartz Glass Sheet

- Electrode Polishing Material for Electrochemical Experiments

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

People Also Ask

- What heat treatment process is required for large casting? Achieve Dimensional Stability and Performance

- What is the heat treatment process for non-ferrous metals? Mastering Annealing and Precipitation Hardening

- How does the sample size affect the needed accuracy of the measurement? Optimize Your Data Quality

- What is the process of thin film formation? A Guide to Atomic-Level Surface Engineering

- What is the product composition of pyrolysis gas? A Guide to Fuel Composition & Control

- What temperature ranges are typically associated with ultra-low temperature freezers? Preserve Samples from -40°C to -86°C

- Does sintering use diffusion? The Atomic Mechanism for Building Stronger Materials

- What are the three steps in the sintering cycle? Master the Process for Stronger Parts