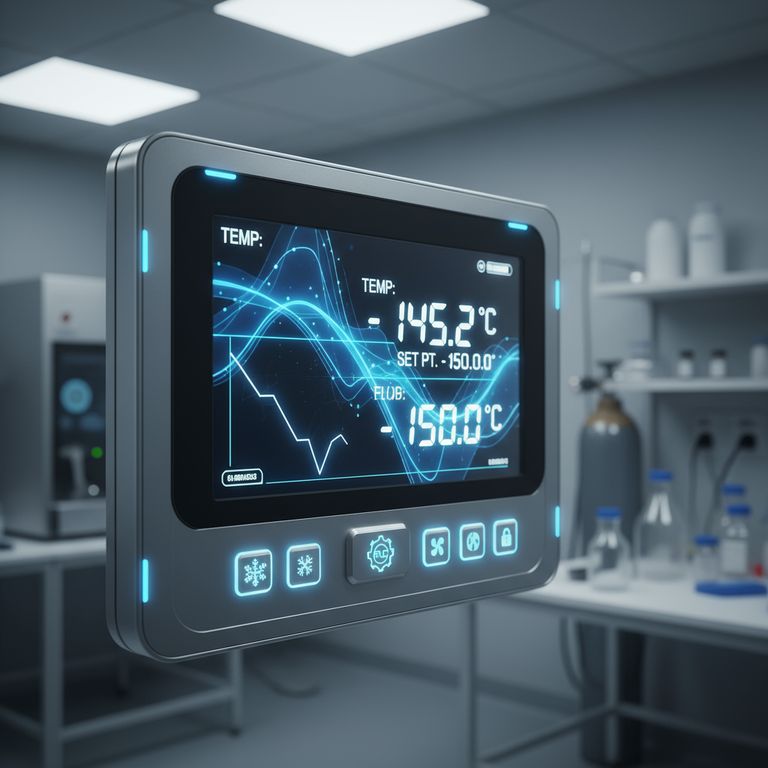

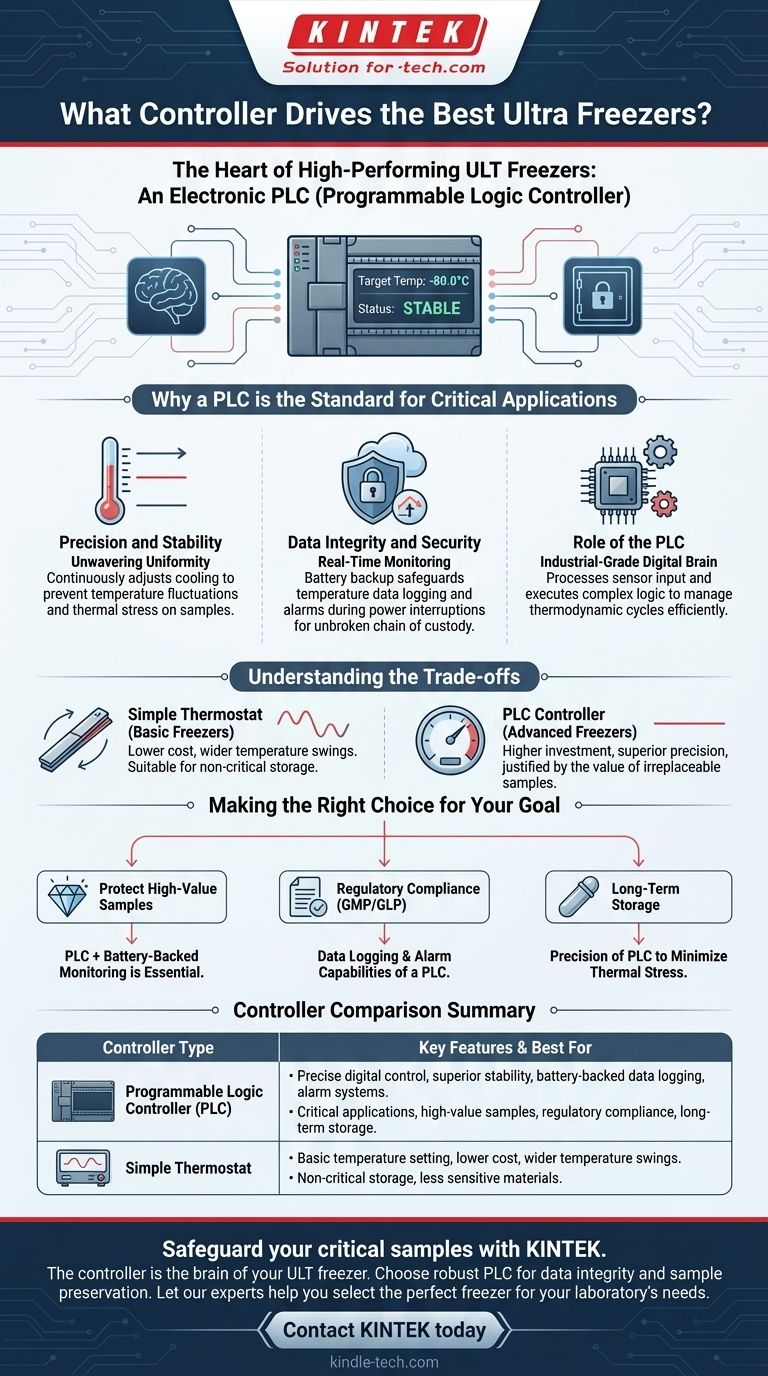

In the highest-performing Ultra-Low Temperature (ULT) Freezers, the control system is centered around an electronic PLC. A PLC, or Programmable Logic Controller, provides the precise digital management required for maintaining extremely stable and uniform temperatures. This system is paired with a clear digital display for monitoring all critical freezing parameters and includes a battery backup to safeguard data during power interruptions.

The choice of a PLC controller isn't just about setting a temperature; it's about ensuring unwavering reliability and data integrity. For valuable scientific or medical samples, the controller is the central nervous system that guarantees their preservation under all conditions.

Why a PLC is the Standard for Critical Applications

A ULT freezer is more than just a cold box; it is a highly specialized piece of equipment designed to protect irreplaceable assets. The controller is the most critical component in fulfilling this mission.

The Role of the PLC

A Programmable Logic Controller (PLC) is an industrial-grade digital computer adapted for the control of manufacturing processes or, in this case, the complex thermodynamic cycles of a ULT freezer.

Unlike a simple mechanical thermostat, a PLC constantly processes input from sensors and executes a pre-programmed logic to manage the cooling system's components.

Precision and Stability

The primary advantage of a PLC is its ability to maintain temperature uniformity and stability with exceptional precision. It continuously adjusts the cooling cycle to prevent the temperature fluctuations inherent in less sophisticated systems.

This micro-management ensures that samples stored inside are not subjected to thermal stress, which could compromise their integrity over long periods.

Data Integrity and Security

Modern ULT freezers managed by PLCs feature digital displays that provide real-time information on temperature, alarms, and system status.

Critically, these systems include a battery backup. This ensures that even during a complete power failure, the controller continues to log temperature data and will sound alarms if thresholds are breached. This provides an unbroken chain of data for regulatory compliance and quality control.

Understanding the Trade-offs

While PLC-controlled systems are superior, it's important to understand the context of their components and what they are designed to achieve.

System Complexity vs. Simple Control

A basic freezer might use a simple bimetallic thermostat, which is inexpensive but prone to wide temperature swings. A PLC is a more complex and costly component, but this investment is justified by the value of the materials being stored.

For non-critical storage, a simpler controller might suffice. For biological samples, pharmaceuticals, or long-term research materials, the precision of a PLC is non-negotiable.

Focus on the Core Function

The references also mention components like air-cooled condensers and capillary tubes for refrigerant expansion. While these are essential parts of the cooling circuit, they are secondary to the controller's function.

The PLC is the "brain" that directs these components to work together efficiently to achieve the desired temperature. The quality of the condenser and fan impacts efficiency, but the PLC dictates their performance.

Making the Right Choice for Your Goal

The selection of a ULT freezer ultimately depends on the value and sensitivity of the items you need to preserve.

- If your primary focus is protecting high-value, irreplaceable samples: A freezer with an electronic PLC controller and battery-backed monitoring is the only acceptable choice.

- If your primary focus is regulatory compliance (e.g., GMP, GLP): The data logging and alarm capabilities of a PLC system are essential for creating an auditable temperature record.

- If your primary focus is long-term storage and stability: The precision of a PLC minimizes thermal stress on samples, ensuring their viability for years to come.

Ultimately, investing in a freezer with a superior PLC controller is an investment in the security and integrity of your critical work.

Summary Table:

| Controller Type | Key Features | Best For |

|---|---|---|

| Programmable Logic Controller (PLC) | Precise digital control, superior temperature stability, battery-backed data logging, alarm systems | Critical applications, high-value samples, regulatory compliance (GMP/GLP), long-term storage |

| Simple Thermostat | Basic temperature setting, lower cost, wider temperature swings | Non-critical storage, less sensitive materials |

Safeguard your most critical samples with the right equipment. The controller is the brain of your Ultra-Low Temperature (ULT) freezer, and choosing a system with a robust PLC is essential for data integrity and sample preservation. At KINTEK, we specialize in providing reliable lab equipment, including ULT freezers designed for precision and compliance. Let our experts help you select the perfect freezer for your laboratory's specific needs. Contact KINTEK today to ensure the security of your valuable work!

Visual Guide

Related Products

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 108L Vertical Ultra Low Temperature ULT Freezer

- 58L Precision Laboratory Ultra Low Temperature Upright Freezer for Critical Sample Storage

- 308L Precision Ultra Low Temperature Freezer for Laboratory Applications

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

People Also Ask

- How is temperature controlled in ultra low temperature freezers? A Guide to Stable -80°C Storage

- What are the key features to look for in an ultra-low temperature freezer for mRNA vaccine storage? Essential Features for Absolute Vaccine Integrity

- Why are ULT freezers considered vital equipment in labs? Ensuring Uncompromised Sample Integrity for Critical Research

- What is the purpose of ultra-low temperature (ULT) freezers? Preserve Critical Biological Samples

- How are advancements in compressor technology and refrigerant fluids improving ULT freezers? Boost Efficiency & Cut Costs