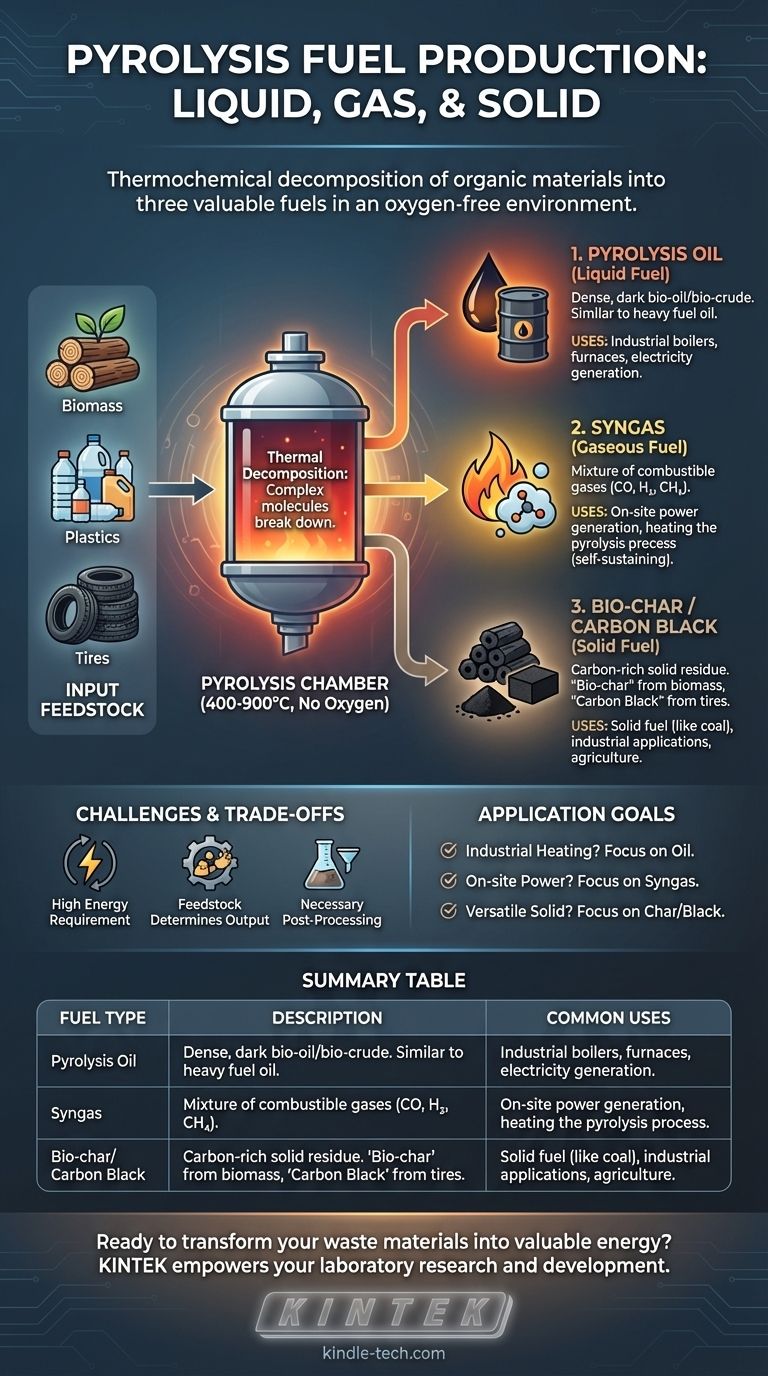

Pyrolysis primarily produces a liquid fuel known as pyrolysis oil or bio-oil. This thermochemical process, which heats organic materials like biomass, plastics, or tires in the absence of oxygen, also simultaneously generates two other valuable fuel byproducts: a combustible gas called syngas and a solid, carbon-rich material known as bio-char.

The critical insight is that pyrolysis doesn't create one single fuel. It deconstructs a feedstock into three distinct outputs—a liquid oil, a combustible gas, and a solid char—each of which has potential as a fuel or a valuable co-product.

What is Pyrolysis? A Controlled Breakdown

The Core Mechanism: Thermal Decomposition

Pyrolysis is not burning. It is the thermal decomposition of a material at high temperatures (typically 400-900°C) inside a sealed, oxygen-free chamber.

Without oxygen, the material cannot combust. Instead, the intense heat breaks down the complex molecules into simpler, smaller ones, which then form new liquid, gaseous, and solid substances.

The Role of Feedstock

The process is versatile and can handle various organic feedstocks. The most common inputs include biomass (like wood or agricultural waste), plastics, and end-of-life tires.

The specific type and quality of the feedstock dramatically influence the final proportion and composition of the fuel outputs.

The Three Primary Fuel Outputs

Pyrolysis Oil (The Liquid Fuel)

This is the main liquid product and the one most commonly referred to as a fuel. It is a dense, dark liquid that is sometimes called bio-oil or bio-crude.

Its properties can be similar to a heavy fuel oil, making it suitable for use in industrial boilers, furnaces, and certain engines to generate heat or electricity.

Syngas (The Gaseous Fuel)

This output is a mixture of combustible gases, primarily carbon monoxide, hydrogen, and methane.

Syngas has a lower energy value than natural gas but is highly useful. It is often captured and immediately used to provide the heat needed to power the pyrolysis process itself, creating a self-sustaining system.

Bio-char / Carbon Black (The Solid Fuel)

The final product is the solid, carbon-rich residue left after the volatile components have been driven off.

When derived from biomass, it is called bio-char. When from tires, it is called carbon black. This material can be burned as a solid fuel, similar to coal, or used in various industrial applications, from agriculture to manufacturing.

Understanding the Trade-offs and Challenges

High Energy Requirement

Pyrolysis is an energy-intensive process. A significant amount of external energy is required to reach and maintain the high temperatures necessary for decomposition, although this can be offset by using the syngas produced.

Feedstock Determines Output

The process is highly sensitive to the input material. The yield and quality of the oil, gas, and char can vary significantly depending on whether you are processing plastic, wood, or tires.

Necessary Post-Processing

The raw pyrolysis oil is not a drop-in replacement for refined fuels like diesel or gasoline. It is often acidic and unstable, requiring further refining or upgrading before it can be used in more demanding applications.

How to Apply This to Your Goal

The "best" fuel from pyrolysis depends entirely on your intended application.

- If your primary focus is a transportable liquid fuel for industrial heating: The pyrolysis oil is your target product, as it can be stored and used in boilers and furnaces.

- If your primary focus is on-site power generation: The syngas is the most direct fuel source, capable of running a generator to create electricity for the facility.

- If your primary focus is a versatile solid material: The bio-char or carbon black is a valuable output that can either be sold as an industrial commodity or used as a solid fuel.

Pyrolysis stands out as a flexible technology that converts low-value materials into a portfolio of valuable energy products.

Summary Table:

| Fuel Type | Description | Common Uses |

|---|---|---|

| Pyrolysis Oil (Liquid) | Dense, dark liquid similar to heavy fuel oil. | Industrial boilers, furnaces, electricity generation. |

| Syngas (Gaseous) | Mixture of combustible gases like CO, H₂, and CH₄. | On-site power generation, heating the pyrolysis process. |

| Bio-char / Carbon Black (Solid) | Carbon-rich solid residue. | Solid fuel (like coal), industrial applications, agriculture. |

Ready to transform your waste materials into valuable energy?

KINTEK specializes in providing robust laboratory equipment to help you research, develop, and optimize pyrolysis processes. Whether you're working with biomass, plastics, or tires, our tools can help you analyze feedstock and maximize the yield of pyrolysis oil, syngas, and bio-char.

Let KINTEK empower your energy innovation. Contact our experts today to discuss how our solutions can meet your specific laboratory needs and help you achieve your fuel production goals.

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Custom PTFE Teflon Parts Manufacturer for Culture Dish and Evaporation Dish

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Large Vertical Graphite Vacuum Graphitization Furnace

- Special Heat Press Mold for Lab Use

People Also Ask

- What are the equipment for pyrolysis laboratory? Choosing the Right Reactor for Your Research

- What is the drying zone in a rotary kiln? Boost Efficiency with Modern Drying Solutions

- What is the meaning of rotary furnace? Achieve Superior Uniformity in Continuous Heat Treatment

- How is the operational mode of bed motion selected for a rotary kiln? Optimize Heat Transfer and Material Homogeneity

- What is a rotary kiln reactor? A Guide to Industrial Thermal Processing