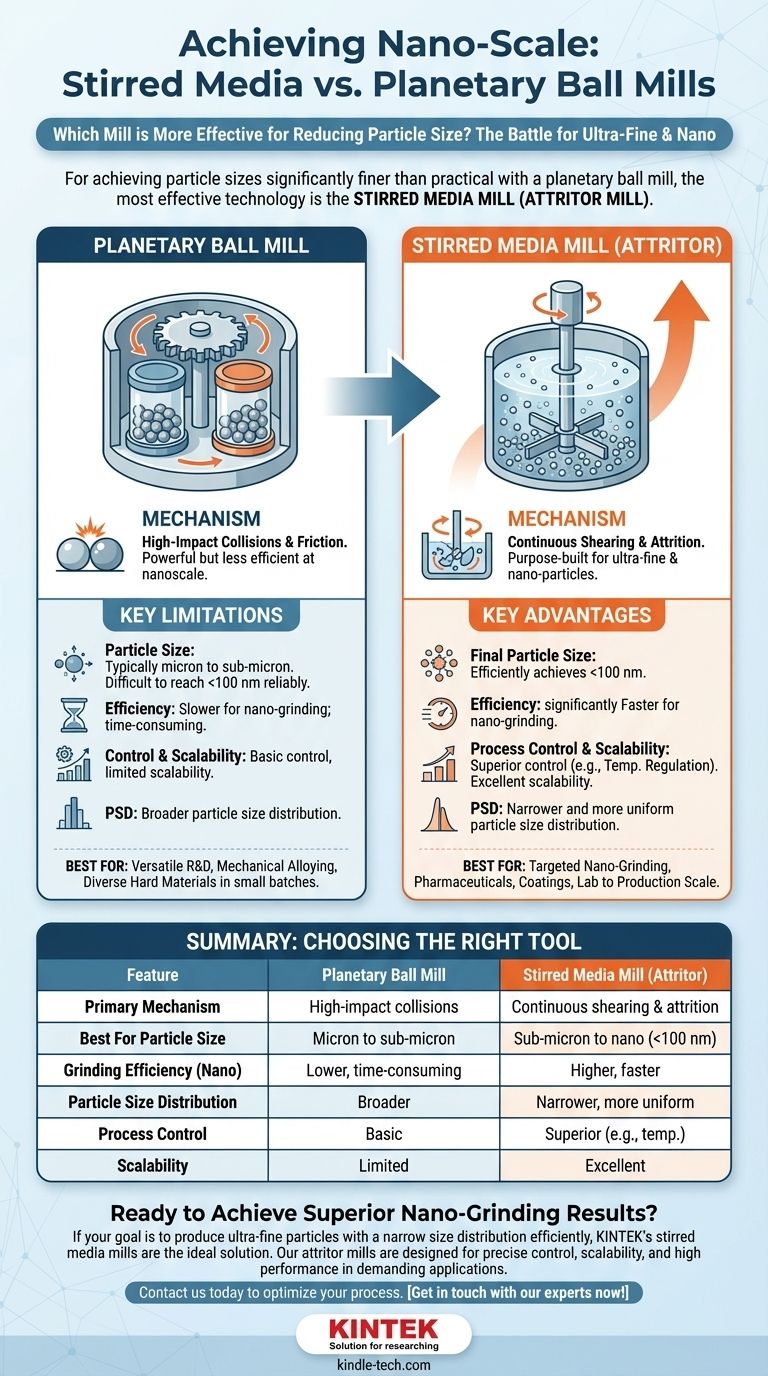

For achieving particle sizes significantly finer than what is practical with a planetary ball mill, the most effective technology is the stirred media mill, often referred to as an attritor mill. While planetary mills are exceptionally powerful, their reliance on high-impact collisions becomes less efficient at the nanoscale. Stirred media mills, by contrast, use a continuous shearing and attrition mechanism that is purpose-built for producing ultra-fine and nano-sized particles with greater control and efficiency.

The choice of a mill is not about finding a universally "better" machine, but about matching the grinding mechanism to your target particle size. Planetary mills excel at high-energy impact, but for controlled, efficient nano-grinding, the continuous shearing action of a stirred media mill is superior.

The Mechanics of High-Energy Milling

To understand why one mill is more effective than another, you must first understand their fundamental operating principles. The method of energy transfer dictates the mill's ultimate capability.

How Planetary Ball Mills Work

A planetary ball mill uses powerful centrifugal forces to generate energy. Grinding jars, containing the sample and grinding media (balls), are mounted on a rotating "sun wheel."

These jars not only revolve around the center of the wheel but also rotate on their own axis in the opposite direction. This combined motion creates extremely high-energy impacts and friction between the balls, the material, and the jar wall, effectively pulverizing the sample. The primary mechanism is high-g-force impact.

The Principle of Stirred Media Mills (Attritors)

A stirred media mill operates differently. It consists of a stationary, often temperature-controlled tank filled with a slurry of the material and very small grinding media.

A central rotating shaft with arms or discs agitates this mixture at high speed. Instead of the chaotic, high-impact collisions of a planetary mill, this creates intense shear forces and continuous friction as the tiny beads interact with the material particles.

Why the Mechanism Matters for Nanoparticles

For breaking down large particles (microns), the high impact of a planetary mill is very effective. However, as particles become smaller and enter the sub-micron or nano range, they can begin to cake or be cushioned by each other, making impact less efficient.

The continuous, high-intensity shearing action of a stirred media mill is far more effective at deagglomerating and breaking down these already-fine particles, providing a more direct and controlled path to creating a stable nanoparticle suspension.

Direct Comparison: Planetary Mill vs. Stirred Media Mill

When your goal is to push beyond the typical limits of a planetary mill, the advantages of a stirred media mill become clear.

Final Particle Size

A stirred media mill can more reliably and efficiently achieve smaller particle sizes, often well below 100 nanometers. Reaching this level in a planetary mill can be extremely time-consuming, difficult to control, and may not be possible for all materials.

Grinding Efficiency and Time

For nano-grinding applications, stirred media mills are significantly faster. The energy is applied more continuously and uniformly throughout the material. A process that might take 24 hours in a planetary mill could potentially be completed in just a few hours in an attritor.

Process Control and Scalability

Stirred media mills offer far superior process control. Most are built with jacketed tanks for precise temperature regulation, which is critical for preventing unwanted phase changes or degradation. They are also inherently designed for scalability from small lab batches to continuous production runs.

Particle Size Distribution (PSD)

Due to the more controlled and consistent grinding mechanism, stirred media mills typically produce a narrower and more uniform particle size distribution. This is a critical requirement for advanced materials used in ceramics, inks, pharmaceuticals, and coatings.

Understanding the Trade-offs and Limitations

No single technology is perfect for every application. Choosing the right mill requires acknowledging the strengths and weaknesses of each.

The Strength of Planetary Mills

Planetary mills are the workhorses of materials science R&D for good reason. They are incredibly versatile, able to handle wet or dry grinding, a huge range of materials (from soft to super-hard), and are the premier tool for mechanical alloying and solid-state synthesis.

For small, exploratory batches where extreme fineness is not the only goal, their simplicity and power are often ideal.

Contamination Concerns

Both systems can introduce contamination from the grinding media and the container walls. The choice of material—zirconia, tungsten carbide, alumina, etc.—is critical in both cases. However, the extreme impact forces in a planetary mill can sometimes lead to higher wear and tear on the media and jars.

Cost and Complexity

Planetary ball mills are generally less expensive and simpler to operate for basic laboratory use. Stirred media mills are more complex systems that represent a larger capital investment, especially as you move toward production-scale equipment.

Making the Right Choice for Your Goal

Your selection depends entirely on your specific material, target particle size, and operational scale.

- If your primary focus is rapid R&D, mechanical alloying, or processing diverse, hard materials in small batches: The versatility and high impact energy of a planetary ball mill make it an excellent choice.

- If your primary focus is achieving the finest possible nano-particles (<100 nm) with a tight distribution at a lab or production scale: A stirred media mill (attritor) is the more effective and efficient technology.

- If your primary focus is achieving fine powders while absolutely preventing media contamination: You should investigate a media-less option like a jet mill, which uses high-velocity gas to cause particle-on-particle collisions.

Understanding the core milling mechanism is the key to selecting the tool that will not just reduce particle size, but will achieve your specific material processing objective.

Summary Table:

| Feature | Planetary Ball Mill | Stirred Media Mill (Attritor) |

|---|---|---|

| Primary Mechanism | High-impact collisions | Continuous shearing and attrition |

| Best For Particle Size | Micron to sub-micron | Sub-micron to nano (<100 nm) |

| Grinding Efficiency (Nano) | Lower, time-consuming | Higher, faster |

| Particle Size Distribution | Broader | Narrower, more uniform |

| Process Control | Basic | Superior (e.g., temperature regulation) |

| Scalability | Limited for production | Excellent for lab to production |

| Ideal Application | Versatile R&D, mechanical alloying | Targeted nano-grinding, pharmaceuticals, coatings |

Ready to achieve superior nano-grinding results?

If your goal is to produce ultra-fine particles with a narrow size distribution efficiently, KINTEK's stirred media mills are the ideal solution. Our attritor mills are designed for precise control, scalability, and high performance in demanding applications like pharmaceuticals, ceramics, and advanced coatings.

Contact us today to discuss how our lab equipment can optimize your particle size reduction process and bring your materials to the next level.

Get in touch with our experts now!

Visual Guide

Related Products

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- High Energy Vibratory Laboratory Ball Mill Double Tank Type

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Four-Body Horizontal Jar Mill

People Also Ask

- How does a process control agent like toluene protect laboratory equipment? Optimize Your High-Energy Ball Milling

- Is a ball mill used for fine grinding? Achieve Micron to Nanometer Particle Sizes

- What is the primary function of a planetary high-energy ball mill in WC-10Co prep? Achieve Sub-Micron Material Refinement

- What is the primary function of high-energy ball milling for FeCrAl ODS alloys? Master Mechanical Alloying Efficiency

- Why is a ball mill used for Fe-Cr-Mn-Mo-N-C composites? Unlock Precision Micro-Scale Homogeneity

- What is the primary function of a planetary ball mill in ODS steel prep? Achieving Nanoscale Mechanical Alloying

- What core function does a high-power ball mill perform for nano-lead powder? Optimize Your Gamma-Ray Shielding

- Why are tungsten carbide grinding balls selected for silicon nitride-alumina synthesis? Achieve 99.95% Ceramic Purity