In short, a standard sieve shaker method is used to determine particle sizes ranging from several millimeters down to approximately 38 micrometers (µm). This technique measures the particle's ability to pass through a specific mesh size, providing a distribution of sizes rather than a single, absolute diameter for any individual particle.

Sieve analysis is a highly reliable and cost-effective method for characterizing granular materials. However, it's critical to understand that the "diameter" it determines is a statistical measurement based on a particle's smallest cross-section, not its true geometric shape, and its effectiveness diminishes for particles smaller than about 40 µm.

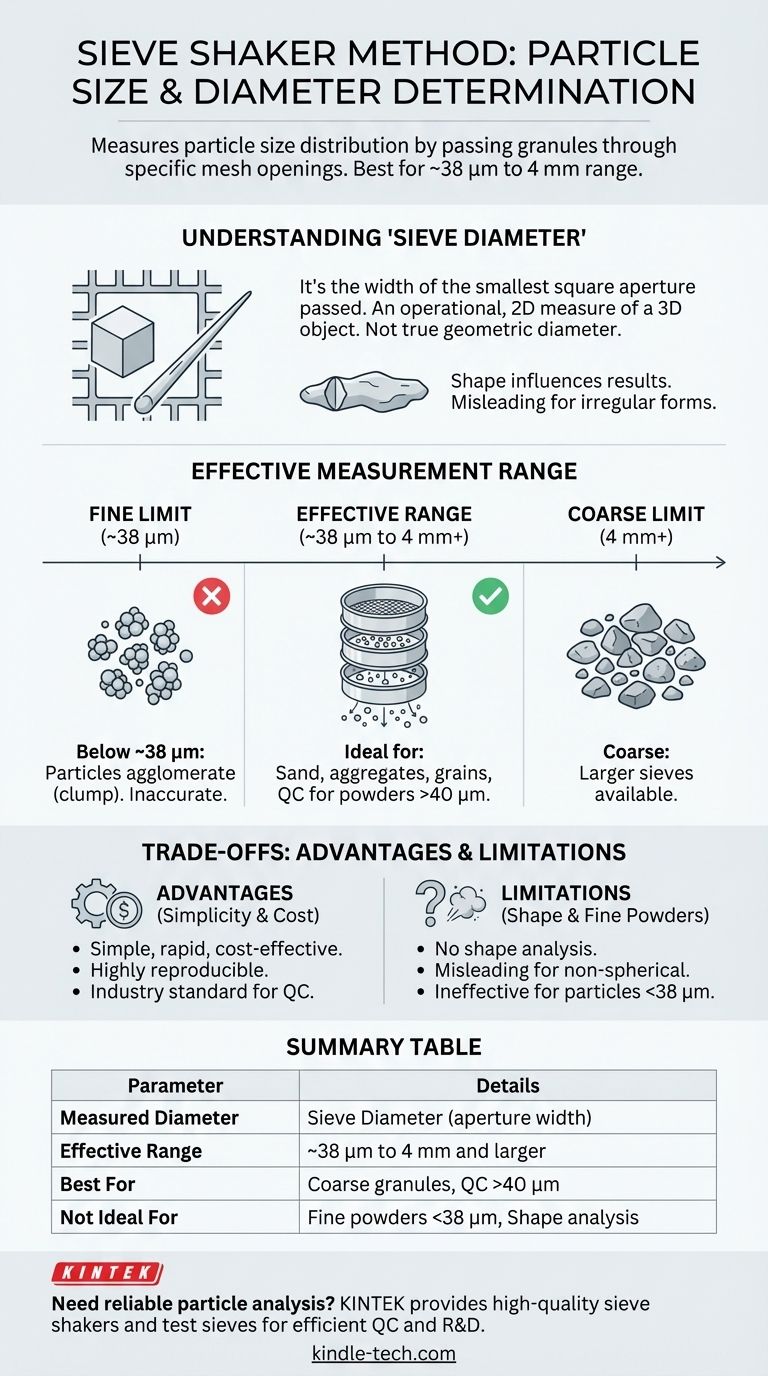

Understanding the "Diameter" in Sieve Analysis

When we discuss the "diameter" of a particle measured by a sieve, we are not referring to a true geometric diameter as you would measure on a perfect sphere. The method provides a different, more practical type of size determination.

The Concept of Sieve Diameter

A sieve shaker works by passing particles through a series of screens with square openings of a known size.

The resulting "sieve diameter" is the width of the smallest square aperture the particle can pass through. This is an operational, two-dimensional measurement of a three-dimensional object.

How Particle Shape Influences Results

This method is most direct for spherical or cubical particles. For irregular shapes, like elongated or flat particles, the measurement can be misleading.

A long, needle-like particle might pass end-on through a hole that is much smaller than its total length. The result is accurate from the sieve's perspective but does not capture the particle's full morphology.

The Practical Measurement Range

Sieve shakers are effective within a specific window of particle sizes. This range is defined by the largest and smallest available mesh openings that provide reliable, repeatable results.

The Upper Limit: Coarse Particles

The upper limit is determined by the coarsest sieve in your stack. Standard test sieves are commonly available with openings of 4 mm and larger.

For very coarse aggregates like gravel, specialized large-format screen shakers are used, but the principle remains the same.

The Lower Limit: The Fine Particle Boundary

The practical lower limit for dry sieve analysis is typically around 38 micrometers (µm), which corresponds to a standard 400-mesh sieve. Some references may cite a general boundary of 50 µm.

Below this threshold, forces like static electricity and moisture cause fine particles to clump together (agglomerate). This prevents them from passing through the mesh correctly, leading to inaccurate and non-reproducible results.

Understanding the Trade-offs

No single method is perfect for all applications. Sieve analysis has clear advantages and limitations that make it suitable for some tasks but not others.

Key Advantage: Simplicity and Cost

As a method, sieve shaking is simple, rapid, and relatively inexpensive compared to more complex techniques like laser diffraction or image analysis. Its results are highly reproducible, making it an industry standard for quality control in many fields.

Key Limitation: Particle Shape Ambiguity

The primary limitation is its inability to account for particle shape. If your goal is to understand the true morphology or aspect ratio of your particles, sieve analysis is insufficient. It only tells you if a particle could fit through a square hole.

Key Limitation: The Fine Powder Problem

As mentioned, the method breaks down for very fine powders. For materials with a significant fraction of particles below 40 µm, alternative methods are required to get an accurate particle size distribution.

Making the Right Choice for Your Sample

To determine if sieve analysis is the right tool, consider your ultimate goal.

- If your primary focus is characterizing coarse granular materials (e.g., sand, aggregates, grains): Sieve analysis is the ideal, cost-effective, and industry-accepted standard.

- If your primary focus is quality control for most powders (e.g., foods, chemicals): This method is excellent for ensuring batch-to-batch consistency for particles down to the 40 µm range.

- If your primary focus is characterizing very fine powders (e.g., pigments, fine cement, aerosols): Sieve analysis is not appropriate; you should use methods like laser diffraction, dynamic light scattering, or image analysis.

By understanding both its range and its principles, you can confidently deploy sieve analysis as a robust tool for particle characterization.

Summary Table:

| Sieve Analysis Parameter | Details |

|---|---|

| Measured Diameter | Sieve Diameter (width of smallest square aperture passed) |

| Effective Range | ~38 micrometers (µm) to 4 mm and larger |

| Lower Limit (Fine) | ~38 µm (400 mesh); limited by particle agglomeration |

| Upper Limit (Coarse) | 4 mm+; larger sieves available for aggregates |

| Best For | Coarse granules, sand, grains, QC for powders >40 µm |

| Not Ideal For | Particles <38 µm, true shape/morphology analysis |

Need to accurately characterize your granular materials?

Sieve analysis is a cornerstone of reliable particle size distribution for materials within the 38 µm to 4 mm range. KINTEK specializes in providing high-quality lab equipment, including robust sieve shakers and full sets of test sieves, to ensure your quality control and R&D processes are efficient, cost-effective, and deliver reproducible results.

Whether you're working with construction aggregates, pharmaceutical powders, or food grains, our experts can help you select the perfect equipment for your specific application.

Contact KINTEK today to discuss your laboratory's particle analysis needs and find the right solution for you!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

People Also Ask

- What is the primary function of a mechanical sieve shaker for biomass analysis? Optimize Particle Size Distribution

- How long do I run my sieve shaker for? Find Your Material's Optimal Sieving Time

- What is the role of a mechanical sieve shaker and standard sieve sets in the grading analysis of crushed glass for concrete? Precision Sieving for Quality Aggregates

- What is the function of a benchtop constant temperature shaker? Optimize AMD Treatment with Precise Kinetic Control

- What is the function of a laboratory shaker during the wet chemical synthesis of Pd/Fe3O4 nanocatalysts?

- How does a constant temperature shaker improve adsorption kinetics? Enhance Tetracycline Removal Accuracy

- What are the primary functions of a laboratory orbital shaker during BMP testing? Maximize Methane Yield Accuracy

- What is the purpose of maintaining a constant rotation speed in a laboratory shaker? Optimize Vanadium Slag Extraction