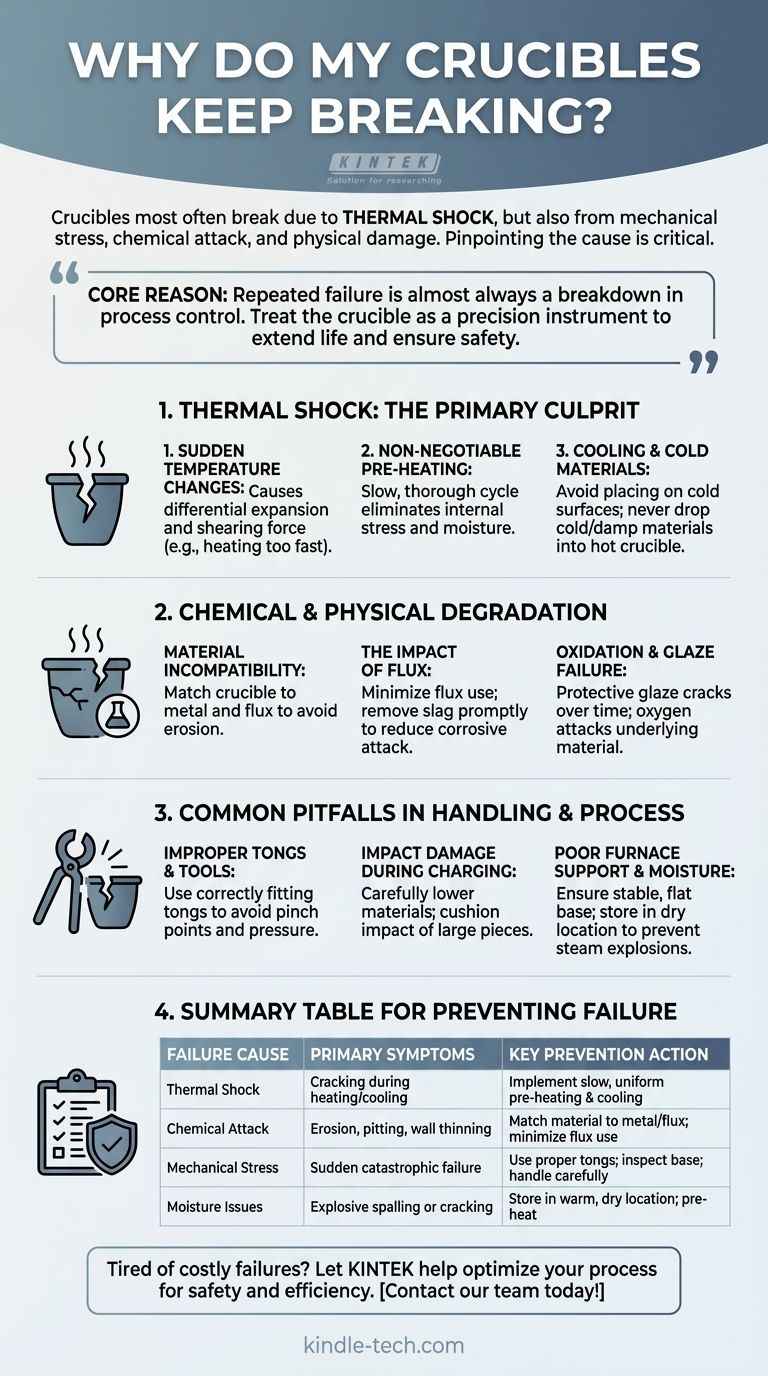

Crucibles most often break due to thermal shock, which is caused by a sudden and uneven change in temperature. Other primary causes include mechanical stress from improper handling, chemical attack from incompatible materials or fluxes, and physical damage from careless charging. Pinpointing the exact failure mode is critical to preventing future incidents.

The core reason for repeated crucible failure is almost always a breakdown in process control. By treating the crucible as a precision instrument and systematically managing its heating, handling, and chemical environment, you can dramatically extend its service life and ensure operational safety.

The Primary Culprit: Thermal Shock

Thermal shock is the single most common cause of crucible failure, especially for materials like clay graphite and silicon carbide. It occurs when one part of the crucible expands or contracts faster than another, creating immense internal stress that leads to cracking.

What Causes This Stress?

Think of the crucible material as a rigid structure. When you heat it too quickly, the inside face gets hot and expands, while the cooler outer face resists that expansion. This differential creates a powerful shearing force that can fracture the material instantly.

The Critical Role of Pre-heating

A slow, thorough pre-heating cycle is non-negotiable. This process allows the entire crucible body to reach a uniform temperature, eliminating the internal stress differentials that cause cracking. It also drives off any absorbed moisture, which can turn to steam and cause a catastrophic failure.

Cooling Too Quickly

The danger isn't over after the pour. Placing a hot crucible on a cold, damp, or conductive surface will cause it to cool unevenly, creating the same thermal shock stresses as improper heating. Always place it on a designated refractory block to cool slowly.

Introducing Cold or Damp Materials

Dropping cold or, even worse, wet ingots and scrap into a red-hot crucible creates a severe, localized thermal shock. This is equivalent to pouring cold water into a hot glass pan and is a frequent cause of immediate failure.

Understanding Chemical and Physical Degradation

Even with perfect heat management, a crucible will eventually wear out. Understanding the nature of this wear can help you identify problems before they lead to a failure.

Material Incompatibility

You must match the crucible to the material you are melting. For example, some fluxes are extremely aggressive and will actively dissolve the binding agents in the crucible wall, leading to erosion, porosity, and eventual collapse.

The Impact of Flux

While necessary for cleaning metals, flux can be highly corrosive to your crucible. Use the minimum amount of flux necessary for the job, add it late in the melt, and remove the slag layer promptly to minimize contact time with the crucible walls.

Oxidation and Glaze Failure

Many crucibles have a protective glaze that prevents oxidation. Over time and with thermal cycling, this glaze can develop micro-cracks. This allows oxygen to attack the underlying graphite or silicon carbide, weakening the structure from the inside out.

Common Pitfalls in Handling and Process

Mechanical stress is a silent killer of crucibles. A small, invisible crack caused by improper handling will quickly propagate and fail under the stress of a thermal cycle.

Improper Tongs and Lifting Tools

Tongs must fit the crucible correctly. Poorly fitting tongs create pinch points that concentrate immense pressure on the crucible wall. Never use generic pliers or ill-fitting tools to lift a crucible, especially when it is hot and at its weakest.

Impact Damage During Charging

Dropping heavy materials into an empty crucible can easily cause cracks or chips, especially at the bottom. Always lower the first pieces of your charge in carefully, or place smaller material in first to cushion the impact of larger pieces.

Poor Furnace Support

The crucible must sit on a flat, stable plinth or base block inside the furnace. An uneven or degraded base creates stress points on the crucible bottom, which will inevitably lead to cracking under the combined weight and heat of a full charge.

The Danger of Moisture

Crucibles, especially clay graphite, are hygroscopic and will absorb moisture from the air. Storing them on a concrete floor or in a damp environment is a recipe for disaster. This absorbed moisture turns to steam violently upon heating, which can crack or even explode the crucible.

A Checklist for Preventing Crucible Failure

Use this guide to diagnose your process and implement corrective actions based on the type of failure you are experiencing.

- If your primary focus is avoiding cracks during heat-up: Implement a strict pre-heating protocol, ensuring the crucible is heated slowly and evenly to temperature before charging.

- If your primary focus is preventing erosion and pitting: Verify your crucible material is compatible with your metal and flux, and minimize the amount and contact time of any flux used.

- If your primary focus is stopping sudden, catastrophic failures: Immediately inspect your lifting tongs, furnace base, and charging methods for sources of mechanical stress and impact.

- If your primary focus is improving overall reliability: Institute a "first in, first out" storage system in a warm, dry location and perform a careful visual inspection for cracks before every single use.

By treating your crucible as a piece of precision equipment rather than a disposable container, you will improve the safety, consistency, and efficiency of your entire operation.

Summary Table:

| Failure Cause | Primary Symptoms | Key Prevention Action |

|---|---|---|

| Thermal Shock | Cracking during heating/cooling | Implement slow, uniform pre-heating and cooling cycles |

| Chemical Attack | Erosion, pitting, wall thinning | Match crucible material to metal/flux; minimize flux use |

| Mechanical Stress | Sudden catastrophic failure | Use proper tongs; inspect furnace base; handle charging carefully |

| Moisture Issues | Explosive spalling or cracking | Store in warm, dry location; pre-heat to drive off moisture |

Tired of costly crucible failures? Let KINTEK help you optimize your process. Our experts specialize in lab equipment and consumables, providing crucibles matched to your specific application and guidance on best practices for handling and maintenance. Ensure the safety and efficiency of your lab operations—contact our team today for a consultation!

Visual Guide

Related Products

- Alumina Al2O3 Ceramic Crucible Semicircle Boat with Lid for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

People Also Ask

- What role do high-purity alumina crucibles play in high-temperature steam oxidation? Ensure Data Integrity up to 1350°C

- Why is a high-purity alumina crucible preferred for high-temperature oxidation? Ensure Unmatched Data Integrity

- What role does an Alumina Crucible play in the high-temperature solid-state synthesis of Na3OBr? Ensure Sample Purity

- What are the advantages of selecting an alumina crucible for TGA? Ensure High-Precision Thermal Analysis Data

- Why are high-purity alumina crucibles used for LATP? Preserve Purity and Conductivity in Sintering