To be precise, the production of biochar is not merely carbon-neutral; it is a leading technology for carbon-negative outcomes. The process actively removes carbon dioxide from the atmosphere by transforming biomass into a highly stable form of carbon that, when added to soil, remains sequestered for centuries or millennia, breaking the natural carbon cycle.

The common perception of biochar as "carbon-neutral" misunderstands its fundamental purpose. Its true value lies in its ability to interrupt the rapid decay of organic matter, creating a net removal of carbon from the atmosphere and locking it away in the ground.

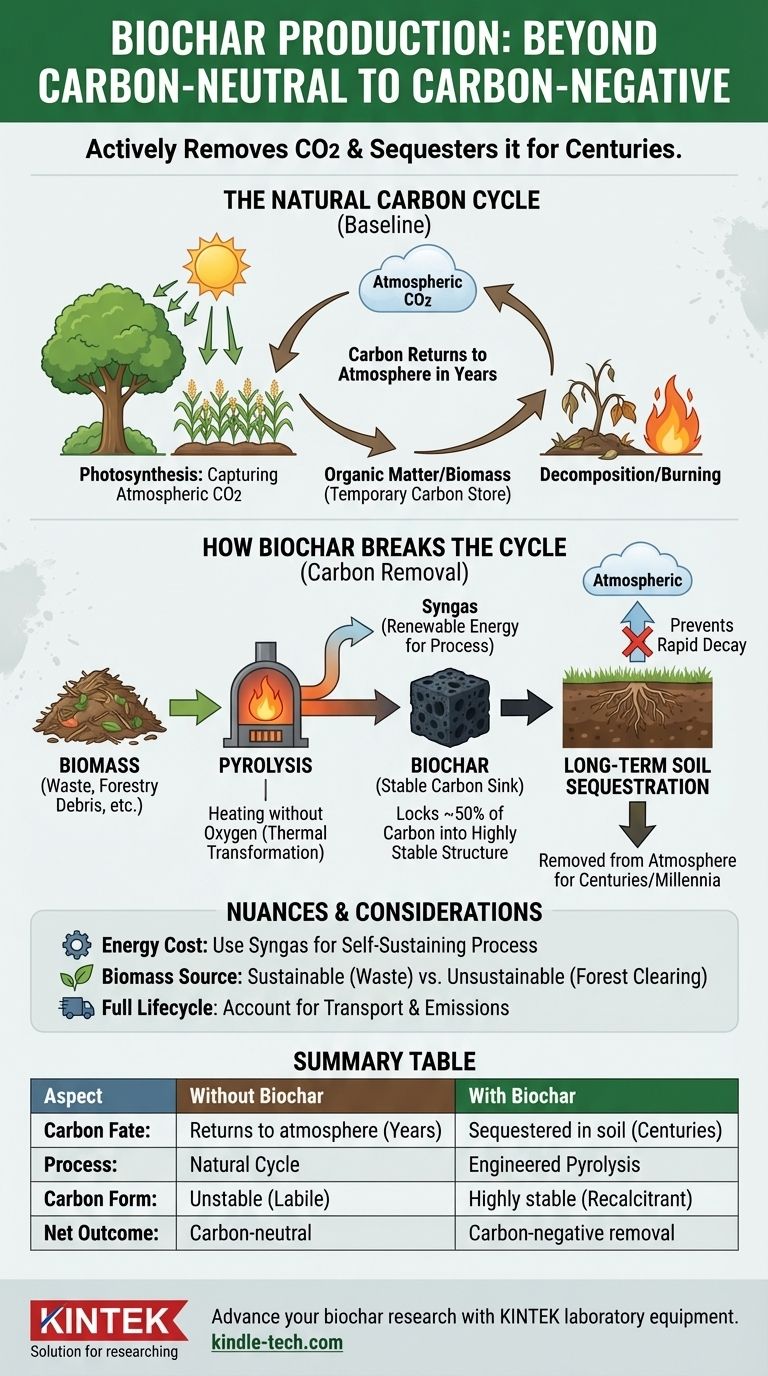

The Carbon Cycle: The Natural Baseline

To understand biochar, we must first look at what happens to organic matter, or biomass, without intervention. This process forms the baseline for what is considered a natural, and largely neutral, carbon cycle over short time scales.

Photosynthesis: Capturing Atmospheric Carbon

All plant life, from trees to agricultural crops, grows by absorbing carbon dioxide (CO2) from the atmosphere through photosynthesis. This process converts atmospheric carbon into the organic compounds that make up the plant's structure (wood, leaves, stems).

Decomposition: The Return to the Atmosphere

When this plant dies, its stored carbon faces one of two fates. It either burns or is consumed by microbes during decomposition. In both scenarios, the vast majority of the carbon is released back into the atmosphere as CO2, completing a relatively fast cycle.

How Biochar "Breaks" the Cycle for Carbon Removal

Biochar production is an engineered intervention that fundamentally alters this natural cycle, turning a temporary carbon store (the plant) into a long-term carbon sink.

Pyrolysis: The Key Transformation

The core of the process is pyrolysis. This involves heating biomass in a low or no-oxygen environment. Instead of burning and releasing its carbon, the material undergoes a thermal and chemical transformation.

This process drives off volatile compounds and water, leaving behind a carbon-rich, charcoal-like substance: biochar. About 50% of the original carbon in the biomass becomes locked into this new, highly stable structure.

Stable vs. Unstable Carbon

The carbon in raw biomass is "labile" or unstable. It is easily broken down by microbes. The carbon in biochar, however, is "recalcitrant" or stable, forming aromatic ring structures that are extremely difficult for microbes to decompose.

Think of the carbon in a dead leaf as sugar—easily and quickly consumed. The carbon in biochar is more like a diamond—incredibly durable and resistant to decay over geological timescales.

Long-Term Sequestration in Soil

When this highly stable biochar is incorporated into soil, it effectively becomes a permanent carbon deposit. Instead of returning to the atmosphere within a few years, the carbon is sequestered for hundreds or even thousands of years, resulting in a net removal of CO2 from the atmosphere.

Understanding the Trade-offs and Nuances

While the core principle is sound, achieving a truly carbon-negative outcome depends on how the process is managed. It is not automatically a net benefit without careful consideration.

The Carbon Cost of Production

The pyrolysis process requires energy to generate heat. If this energy comes from burning fossil fuels, it creates a "carbon debt" that reduces the overall climate benefit of the biochar produced.

The most effective systems use the combustible gases (syngas) produced during pyrolysis itself to power the operation, creating a self-sustaining and much more carbon-efficient loop.

The Source of Biomass Matters

The carbon benefit is only legitimate if the biomass is sourced sustainably. Using agricultural waste, forest debris that would otherwise fuel wildfires, or dedicated perennial grasses are ideal.

Conversely, clearing established forests to create biochar would be a catastrophic net loss for the climate, as it would destroy a functioning carbon sink.

The Full Lifecycle Analysis

A true accounting must consider the entire lifecycle, including emissions from transporting the biomass to the facility and distributing the final biochar. These factors can chip away at the net carbon negativity, making local, decentralized production models more attractive.

Making the Right Choice for Your Goal

Evaluating the climate impact of a biochar project requires looking beyond the simple claim of carbon removal and assessing the entire system.

- If your primary focus is maximizing carbon removal: Prioritize biochar produced using waste biomass where the production process is powered by its own syngas or other renewable energy sources.

- If your primary focus is agricultural improvement: Look for biochar with properties matched to your soil type, as its benefits for water retention and nutrient availability are a key co-benefit of sequestration.

- If your primary focus is a holistic assessment: Demand a full lifecycle analysis (LCA) that accounts for biomass sourcing, transportation, and energy inputs to verify the net-negative carbon claim.

Biochar is a powerful tool not for neutralizing emissions, but for actively reversing them by taking carbon out of the air and returning it to the earth.

Summary Table:

| Aspect | Without Biochar | With Biochar |

|---|---|---|

| Carbon Fate | Returns to atmosphere in years via decomposition/burning | Sequestered in soil for centuries/millennia |

| Process | Natural carbon cycle | Engineered pyrolysis (heating without oxygen) |

| Carbon Form | Unstable (labile) | Highly stable (recalcitrant) |

| Net Outcome | Carbon-neutral cycle | Carbon-negative removal |

Ready to explore how biochar technology can help your organization achieve carbon-negative goals?

At KINTEK, we specialize in advanced laboratory equipment and consumables essential for researching and optimizing biochar production processes, including pyrolysis systems and analysis tools. Our solutions support scientists and engineers in developing efficient, sustainable carbon sequestration methods.

Contact our experts today via our Contact Form to discuss how our lab equipment can accelerate your biochar and carbon removal projects.

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

People Also Ask

- How is a vibratory sieve shaker used in the particle size analysis of mechanically alloyed powders? Expert Guide

- What is the function of sieving equipment in CuAlMn alloys? Master Pore Size Precision

- What are the specifications for test sieves? A Guide to ASTM & ISO Standards for Accurate Particle Analysis

- What is the primary function of a mechanical sieve shaker for biomass analysis? Optimize Particle Size Distribution

- Why is a precision vibrating sieve shaker essential for metal leaching research? Optimize Your Particle Size Analysis