From a climate perspective, biomass is considered a better energy source than coal primarily because it recycles carbon already in the atmosphere, unlike coal which releases vast amounts of new, fossilized carbon. While burning biomass does release CO2, the plants used for the fuel previously absorbed that same amount of CO2 from the atmosphere. This creates a closed-loop system, provided the biomass is sourced and regrown sustainably.

The core advantage of biomass over coal is its role in the short-term carbon cycle, which can make it a low-carbon or carbon-neutral fuel. However, this superiority is not absolute; it is entirely conditional on the sustainability of the biomass source and the efficiency of the energy conversion technology.

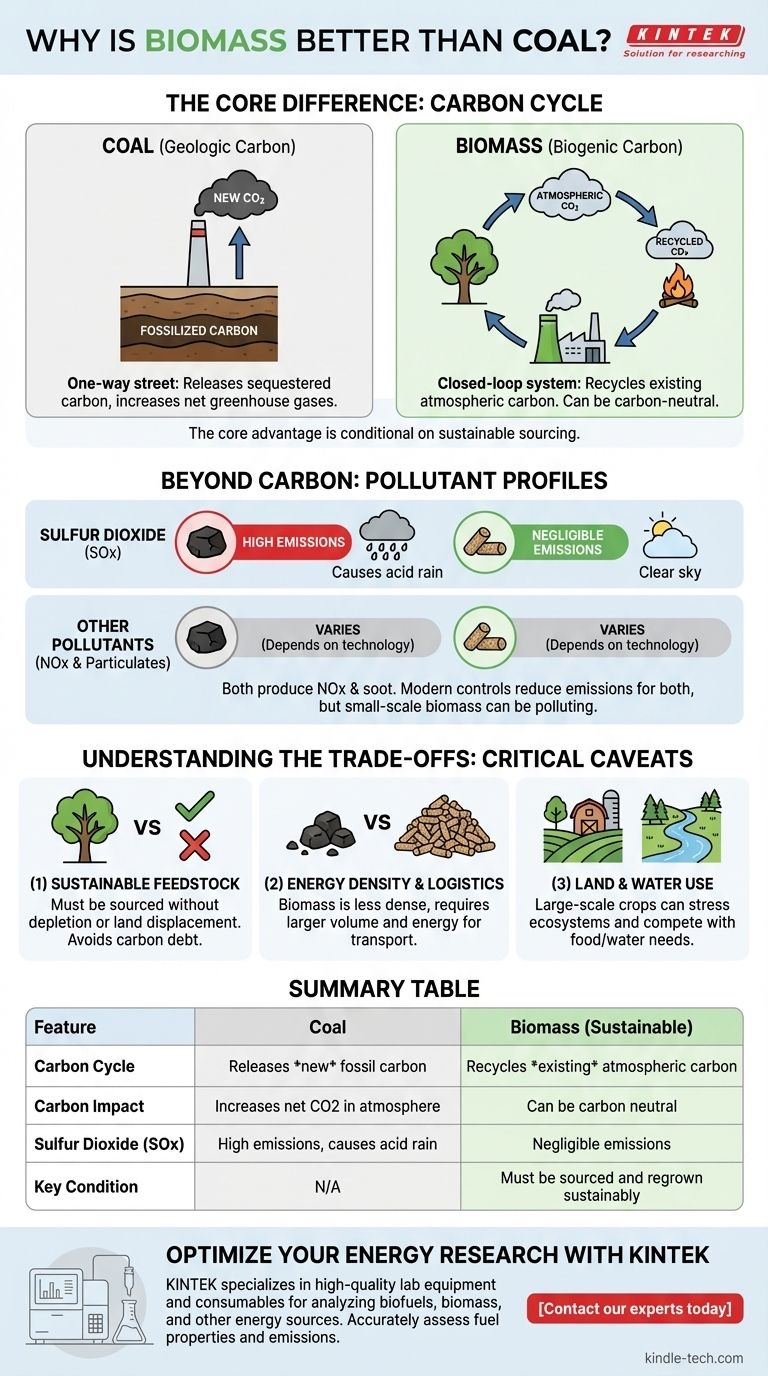

The Core Difference: Geologic vs. Biogenic Carbon

The fundamental distinction between coal and biomass lies in the origin of the carbon they release. This difference has profound implications for the global climate.

Coal: Releasing Sequestered Carbon

Coal is a fossil fuel formed from organic matter that was buried hundreds of millions of years ago. The carbon within it was part of an ancient atmosphere but has been locked away deep underground, effectively removed from the planetary system.

When we burn coal, we are taking this geologic carbon and re-introducing it into today's atmosphere as CO2. This is a one-way street that directly increases the net concentration of greenhouse gases, driving long-term climate change.

Biomass: A Closed-Loop Carbon Cycle

Biomass refers to organic material from plants or animals, such as wood, agricultural crops, or organic waste. The carbon within it is biogenic carbon.

This carbon was absorbed from the atmosphere by plants through photosynthesis during their relatively short lifetime. When biomass is burned for energy, it releases this CO2 back into the atmosphere, where it can then be reabsorbed by new plant growth. In principle, as long as the biomass is replenished at the same rate it is consumed, the process is carbon neutral.

Beyond Carbon: Comparing Pollutant Profiles

While carbon is the main story, other emissions are also a critical part of the comparison.

Sulfur Dioxide (SOx): A Clear Advantage for Biomass

Coal is often high in sulfur content. When burned, it releases sulfur dioxide (SOx), a primary cause of acid rain and a significant contributor to respiratory illnesses.

Biomass, by contrast, contains negligible amounts of sulfur. Its use for energy generation virtually eliminates SOx emissions compared to unabated coal combustion.

Other Pollutants: A More Nuanced Picture

Both fuels produce nitrogen oxides (NOx) and particulate matter (soot) during combustion, which contribute to smog and local air pollution.

While coal is historically a major source of these pollutants, modern coal plants use advanced scrubbers and filters to capture a large percentage of them. Similarly, the emissions from biomass depend heavily on the moisture content of the fuel and the sophistication of the combustion facility. An advanced biomass plant can have very low emissions, but a small-scale or outdated burner can be a significant source of local air pollution.

Understanding the Trade-offs: When Biomass Isn't Better

The environmental case for biomass is strong but comes with critical caveats. Ignoring them leads to poor decision-making and unintended negative consequences.

The Critical Role of a Sustainable Feedstock

The entire "carbon neutral" argument for biomass collapses if the feedstock is not sourced sustainably. If forests are clear-cut for fuel and not replanted, or if a slow-growing, old-growth forest is burned, it creates a "carbon debt" that could take decades or centuries to repay.

Furthermore, if energy crops displace land that was previously used for food production, it can create food security issues and drive up prices.

Energy Density and Logistical Challenges

Biomass is much less energy-dense than coal. You need a significantly larger volume and weight of wood pellets, for example, to produce the same amount of heat as a piece of coal.

This low density creates logistical hurdles. Transporting bulky biomass from where it is grown to the power plant requires energy, which in turn produces emissions that must be accounted for in its lifecycle assessment.

Land and Water Use Implications

Large-scale cultivation of dedicated energy crops requires significant amounts of land and water. This can place stress on local ecosystems, reduce biodiversity, and compete with the water needs of agriculture and local populations.

Making an Informed Assessment

Choosing between energy sources requires a holistic view of their entire lifecycle. Your "better" option depends on what environmental outcome you are prioritizing.

- If your primary focus is reducing long-term atmospheric CO2: Sustainably sourced biomass is superior to coal because it avoids introducing new fossil carbon into the active carbon cycle.

- If your primary focus is preventing acid rain: Biomass is the clear winner due to its near-zero sulfur content.

- If your primary focus is land use and biodiversity: The choice is complex. Coal mining has a direct, destructive footprint, but unsustainable biomass harvesting or large-scale energy crop cultivation can also have severe negative impacts.

Ultimately, evaluating an energy source requires looking beyond the smokestack to the entire lifecycle of the fuel.

Summary Table:

| Feature | Coal | Biomass (Sustainable) |

|---|---|---|

| Carbon Cycle | Releases new fossil carbon | Recycles existing atmospheric carbon |

| Carbon Impact | Increases net CO2 in atmosphere | Can be carbon neutral |

| Sulfur Dioxide (SOx) | High emissions, causes acid rain | Negligible emissions |

| Key Condition | N/A | Must be sourced and regrown sustainably |

Optimize your energy or research processes with the right equipment. KINTEK specializes in high-quality lab equipment and consumables for analyzing biofuels, biomass, and other energy sources. Our solutions help you accurately assess fuel properties and emissions, ensuring your sustainability goals are met. Contact our experts today to find the perfect equipment for your laboratory's needs.

Visual Guide

Related Products

- FS Electrochemical Hydrogen Fuel Cells for Diverse Applications

- Customizable Fuel Cell Stack Components for Diverse Applications

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- High Purity Zinc Foil for Battery Lab Applications

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- What is the significance of using high-purity, corrosion-resistant electrolytic cells? Ensure Quality PEO Coatings

- What system-level maintenance is important for a proton exchange membrane? Ensure Longevity with Proactive System Care

- What is a proton exchange membrane? The Selective Heart of Hydrogen Energy Systems

- What are the technical advantages of using ceramic materials as membranes in MFC stacks? Boost Scalability and Durability

- What structural advantages do PEM electrolyzers offer? Compact, High-Density Hydrogen Production Solutions