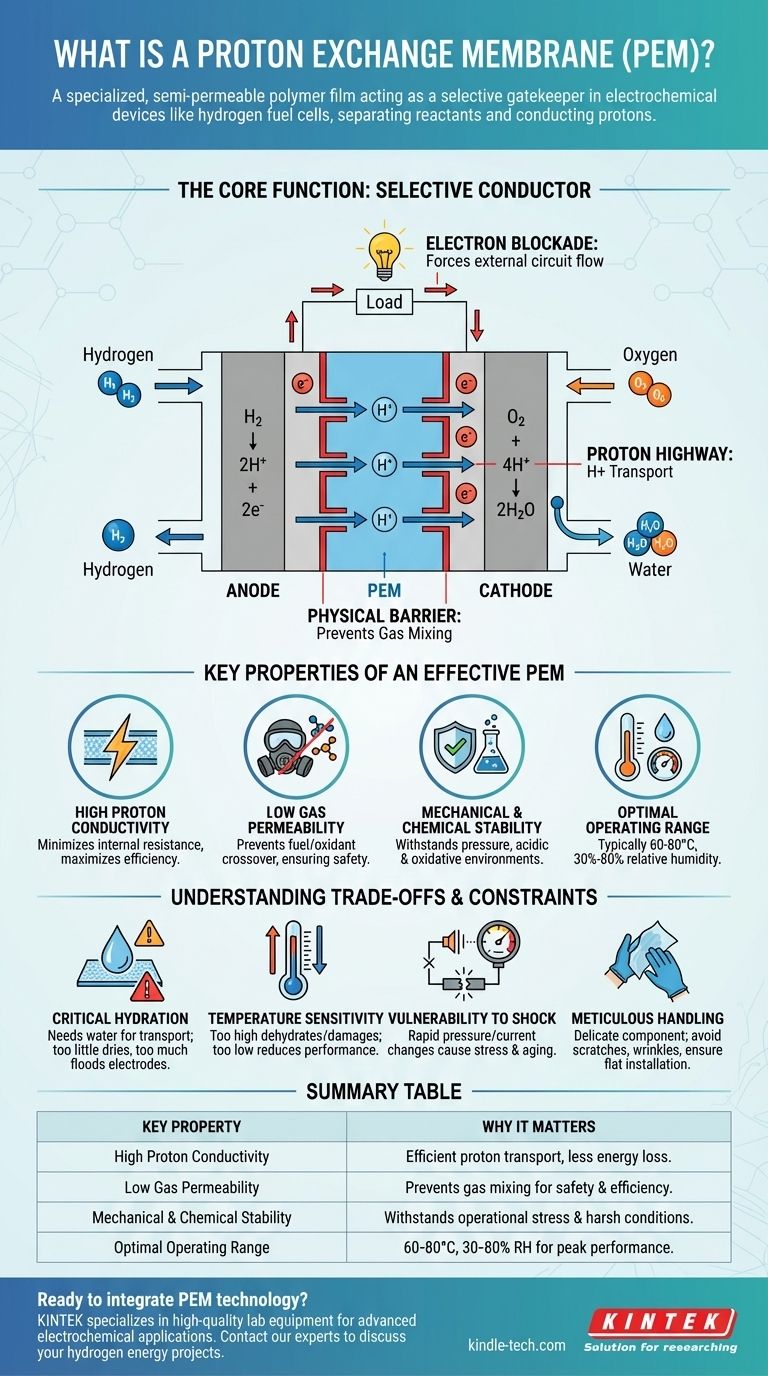

A proton exchange membrane, or PEM, is a specialized polymer film that acts as a highly selective gatekeeper. It is a semi-permeable barrier at the heart of electrochemical devices like hydrogen fuel cells and water electrolyzers. Its fundamental purpose is to physically separate reactants while providing a dedicated pathway for protons (hydrogen ions) to travel from one electrode to the other, all while blocking the passage of electrons and gas molecules.

The PEM's unique ability to conduct protons while acting as an electrical and gas insulator is the core principle that enables modern hydrogen energy technologies. Understanding its operational requirements is not just about performance; it's about the fundamental viability and longevity of the entire system.

The Core Function: A Selective Conductor

A PEM serves three critical roles simultaneously. The success of the entire electrochemical cell depends on how well the membrane performs these functions.

The Physical Barrier

The membrane is a thin but durable film that separates the anode (negative electrode) from the cathode (positive electrode). This prevents the fuel (e.g., hydrogen gas) and the oxidant (e.g., oxygen gas) from mixing directly, which would cause a short circuit and render the device useless.

The Proton Highway

The polymer material of the PEM, often containing sulfonic acid groups, creates a network of channels that can transport protons (H⁺). When properly hydrated, these protons can "hop" from one acidic site to the next, effectively flowing through the membrane.

The Electron Blockade

Crucially, the PEM is an excellent electrical insulator. It does not allow electrons to pass through. This forces the electrons, which are stripped from the hydrogen atoms at the anode, to travel through an external circuit to reach the cathode. This flow of electrons through the external circuit is the usable electric current.

Key Properties of an Effective PEM

Not all polymer films can function as a PEM. They must possess a specific combination of properties to operate efficiently and reliably.

High Proton Conductivity

The primary measure of a PEM's performance is how easily it allows protons to pass through. High conductivity minimizes internal resistance, leading to greater efficiency in the fuel cell or electrolyzer.

Low Gas Permeability

An effective membrane must be highly resistant to "gas crossover." This ensures that fuel and oxidant gases stay on their respective sides, maximizing the efficiency of the reaction and maintaining safety.

Mechanical and Chemical Stability

The membrane must be strong enough to withstand the pressure differences and physical stresses within the device. It also needs to resist degradation from the highly acidic and oxidative environment present during operation.

Understanding the Trade-offs and Operating Constraints

The PEM is the most sensitive component in a hydrogen fuel cell or electrolyzer. Its performance is directly tied to a narrow set of operating conditions.

The Critical Role of Hydration

A PEM must be sufficiently hydrated with water to facilitate proton transport. If it dries out, its conductivity plummets, and it can become brittle and crack. Conversely, too much water ("flooding") can block the pores of the electrodes, preventing reactant gases from reaching the catalyst sites.

Sensitivity to Temperature and Humidity

Most PEMs operate best in a specific range, typically 60-80°C with a relative humidity between 30%-80%. Temperatures that are too high can dehydrate and permanently damage the membrane, while conditions that are too low will reduce its conductivity and overall performance.

Vulnerability to Shock and Stress

Rapid changes in pressure or current during startup and shutdown can physically stress the membrane, leading to micro-tears or premature aging. Likewise, prolonged operation at very high current densities can accelerate its degradation.

Meticulous Handling and Installation

The PEM is a delicate component. It must be handled carefully to avoid scratches or punctures. During installation, it must be placed perfectly flat without wrinkles or stretching, and it requires a tight, uniform fit against the electrodes to minimize electrical resistance.

Applying This Knowledge in Practice

Your approach to using PEM technology depends entirely on your goal. Understanding these principles allows you to avoid common points of failure.

- If your primary focus is system design: You must select a membrane whose properties (thickness, conductivity, stability) are matched to the specific temperature, pressure, and humidity conditions of your application.

- If your primary focus is operation and maintenance: You must prioritize the strict control of operating conditions, particularly hydration and temperature, to ensure both peak performance and maximum device lifespan.

- If your primary focus is handling and assembly: You must treat the membrane as a high-precision component, ensuring it remains clean, undamaged, and is installed with care to prevent leaks and high contact resistance.

Ultimately, the proton exchange membrane is the sophisticated heart of modern hydrogen energy systems, and its precise management is the key to unlocking their full potential.

Summary Table:

| Key Property | Why It Matters |

|---|---|

| High Proton Conductivity | Enables efficient proton transport, minimizing energy loss. |

| Low Gas Permeability | Prevents fuel/oxidant mixing, ensuring safety and efficiency. |

| Mechanical & Chemical Stability | Withstands operational stresses and harsh acidic environments. |

| Optimal Operating Range | 60-80°C with 30-80% relative humidity for peak performance. |

Ready to integrate PEM technology into your lab's research or development? KINTEK specializes in providing the high-quality lab equipment and consumables necessary for advanced electrochemical applications. Our experts can help you select the right tools to ensure the precise handling, testing, and operation of proton exchange membranes. Contact our team today to discuss how we can support your hydrogen energy projects and enhance your laboratory's capabilities.

Visual Guide

Related Products

- Proton Exchange Membrane for Batteries Lab Applications

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- FS Electrochemical Hydrogen Fuel Cells for Diverse Applications

- Customizable Fuel Cell Stack Components for Diverse Applications

- Electrolytic Electrochemical Cell with Five-Port

People Also Ask

- How should a proton exchange membrane be installed? A Guide to Flawless Assembly for Peak Performance

- What are the primary roles of a Proton Exchange Membrane (PEM) in a dual-chamber MFC? Enhance Your Fuel Cell Efficiency

- What are the procedures for handling a proton exchange membrane after use? Ensure Longevity and Performance

- Why is humidity control critical for PEM maintenance? Achieve Peak Performance and Longevity

- What initial steps are required before using a new proton exchange membrane? Ensure Peak Performance and Longevity