Humidity control is the most critical operational parameter for maintaining a proton exchange membrane (PEM). This is because the membrane operates within a narrow hydration window. If the membrane becomes too dry, its ability to conduct protons collapses, crippling performance. Conversely, if it becomes too wet, the electrodes flood with liquid water, which physically blocks reactant gases and suffocates the electrochemical reaction.

The core challenge of PEM maintenance is not just about providing water, but about achieving a precise and constant water balance. The membrane must remain sufficiently hydrated to facilitate ion transport without becoming so saturated that it obstructs the very gases needed to generate power.

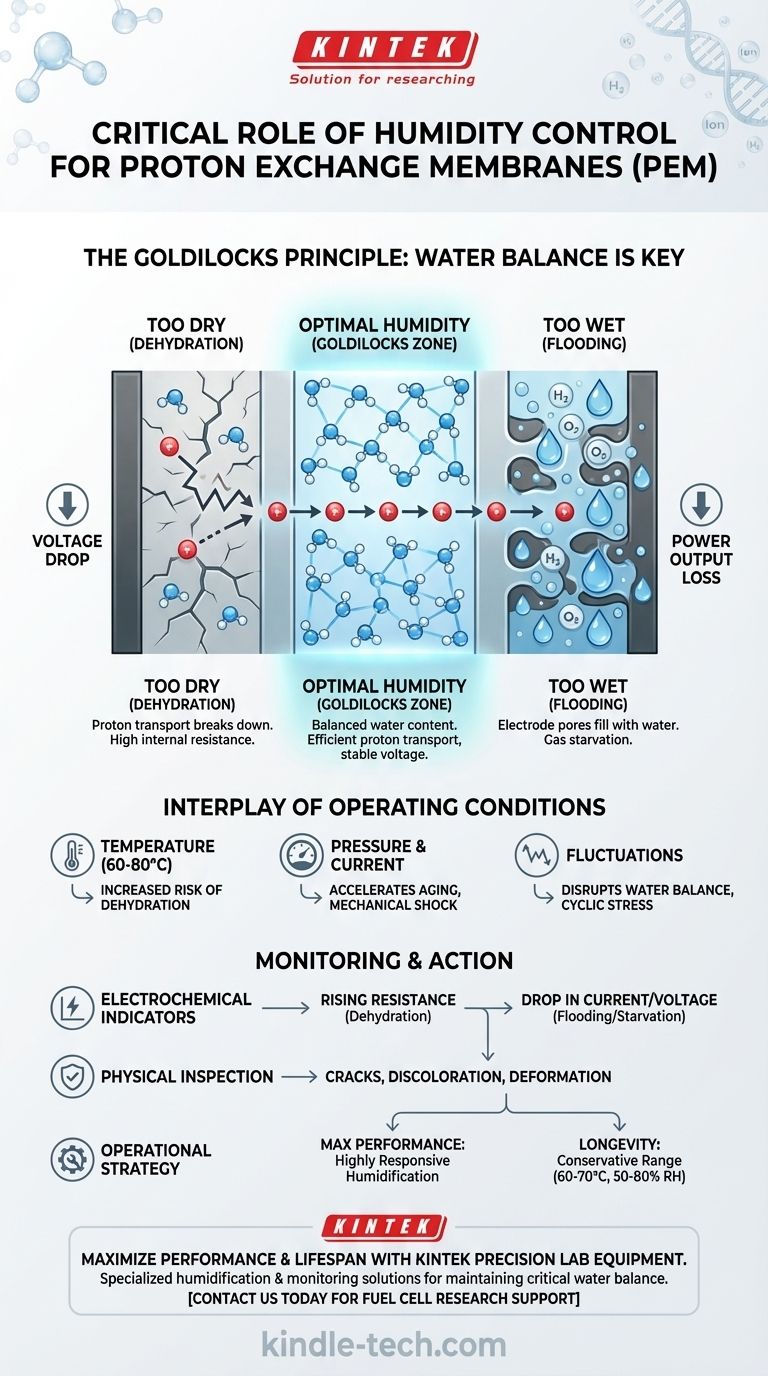

The "Goldilocks" Principle: Why Water Balance is Key

A PEM's function is entirely dependent on its water content. Both extremes—too little or too much—lead to immediate and significant performance degradation.

The Problem of Dehydration

A PEM's primary job is to transport protons. It accomplishes this through a network of water molecules within its polymer structure. Protons essentially "hop" from one water molecule to the next.

When the membrane dries out, this molecular network breaks down. The pathway for proton transport is severed, causing a dramatic increase in internal resistance and a corresponding drop in cell voltage and efficiency.

The Problem of Flooding

While water is essential, an excess of liquid water is equally detrimental. The electrodes surrounding the membrane are porous, designed to allow reactant gases (hydrogen and oxygen) to reach the catalyst sites.

When too much water is present, it condenses and fills these pores. This "flooding" creates a physical barrier that prevents the gases from diffusing to where they are needed, effectively starving the reaction and causing a sharp drop in power output.

How Proper Hydration is Achieved

The most common method for maintaining this balance is to precisely control the humidity of the reactant gases before they enter the fuel cell stack. By using a humidifier, operators can ensure the gases deliver the right amount of water vapor to keep the membrane in its ideal hydration state.

Beyond Humidity: The Interplay of Operating Conditions

Effective humidity control cannot be managed in isolation. It is directly linked to other critical operating parameters that influence the water balance within the cell.

The Impact of Temperature

PEM fuel cells typically operate between 60-80°C. Higher temperatures can increase reaction efficiency but also significantly accelerate water evaporation from the membrane, increasing the risk of dehydration. Therefore, as operating temperature increases, the required humidity of the inlet gases must also increase to compensate.

The Role of Pressure and Current

Operating at a high current density or high pressure can accelerate membrane aging. More importantly, sudden changes in these conditions can cause mechanical shock to the membrane, leading to cracks or pinholes. Gradual startups and shutdowns are crucial to prevent this type of irreversible damage.

Understanding the Risks and Pitfalls

Managing PEM hydration involves inherent trade-offs and requires a systems-based approach to avoid common failure modes.

Performance vs. Longevity

Pushing a fuel cell for maximum performance by running it at high temperatures and current densities places immense stress on the water management system. This aggressive operation often comes at the cost of the membrane's lifespan.

The Danger of Fluctuations

Stable operation is key. Rapid changes in temperature, pressure, or gas flow can disrupt the delicate water balance, causing the membrane to swing between dehydration and flooding. These cycles can induce mechanical stress and accelerate degradation.

Diagnostic Challenges

It can be difficult to distinguish between problems caused by flooding and those caused by dehydration based on performance data alone, as both can lead to a drop in voltage. This requires careful monitoring of other parameters like internal resistance and gas flow rates.

Monitoring Your Membrane's Health

Proactive monitoring is essential for identifying hydration issues before they cause permanent damage.

Electrochemical Indicators

Periodically check the cell's key performance metrics. A gradual increase in internal resistance is a classic sign of membrane dehydration. A sudden drop in output current or open-circuit voltage can indicate severe flooding or fuel starvation.

Physical Inspection

When possible, a visual inspection of the membrane can reveal critical issues. Look for any signs of cracks, discoloration, or physical deformation, which indicate that the membrane has been compromised and needs to be addressed.

Applying This to Your Goal

Your operational strategy should be dictated by your primary objective.

- If your primary focus is maximum performance: You must implement a highly responsive humidification system capable of preventing dehydration, even at elevated operating temperatures and current densities.

- If your primary focus is system longevity: Operate within a conservative temperature and humidity range (e.g., 60-70°C, 50-80% RH) and prioritize stability over peak output.

- If you are diagnosing poor performance: Use internal resistance as a key indicator—a rising resistance points toward a drying membrane, while stable resistance during a voltage drop may suggest electrode flooding.

Ultimately, mastering the dynamic balance of water within the membrane is the foundation of reliable and high-performing PEM systems.

Summary Table:

| Condition | Impact on PEM | Result |

|---|---|---|

| Too Dry (Dehydration) | Proton transport network breaks down | High internal resistance, voltage drop |

| Too Wet (Flooding) | Electrode pores fill with liquid water | Gas starvation, power output loss |

| Optimal Humidity | Balanced water content for ion transport | Stable voltage, efficient power generation |

Maximize the performance and lifespan of your PEM fuel cell systems with KINTEK's precision lab equipment.

Our specialized humidification and monitoring solutions are designed to help you maintain the critical water balance your membrane requires. Whether you're focused on peak performance or long-term reliability, KINTEK provides the reliable tools and consumables your laboratory needs.

Contact us today to discuss how we can support your fuel cell research and development!

Visual Guide

Related Products

- Proton Exchange Membrane for Batteries Lab Applications

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- Anion Exchange Membrane for Laboratory Use

- Thin-Layer Spectral Electrolysis Electrochemical Cell

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

People Also Ask

- What is the function of perfluorinated sulfonic acid proton exchange membranes in the preparation of biomimetic sensors?

- What are the primary roles of a Proton Exchange Membrane (PEM) in a dual-chamber MFC? Enhance Your Fuel Cell Efficiency

- What initial steps are required before using a new proton exchange membrane? Ensure Peak Performance and Longevity

- What is a proton exchange membrane? The Selective Heart of Hydrogen Energy Systems

- What is the function of a PEM in an MFC? Optimize Proton Migration & Power Efficiency