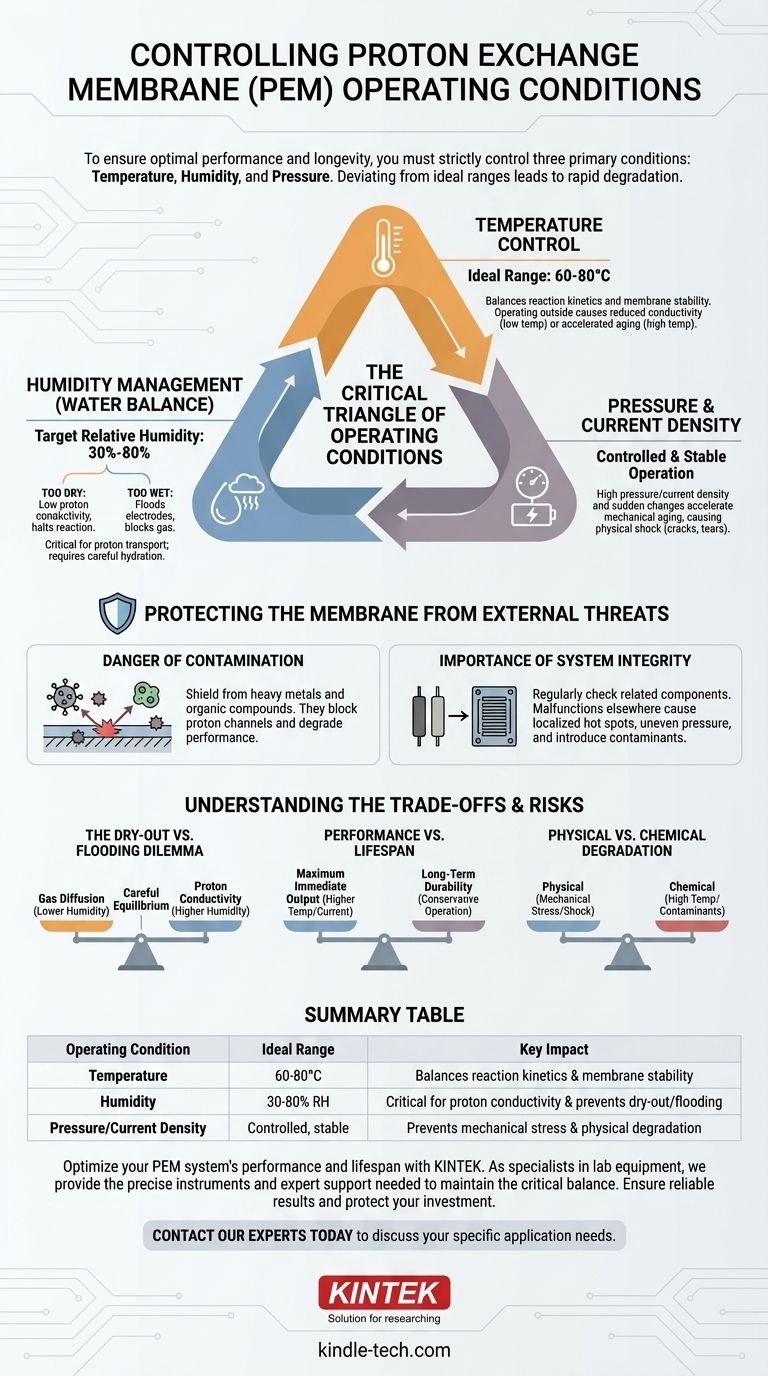

To ensure optimal performance and longevity, you must strictly control three primary operating conditions when using a proton exchange membrane (PEM): temperature, humidity, and pressure. These factors directly govern the membrane's core function—proton conductivity—and deviating from their ideal ranges can lead to rapid performance degradation and irreversible damage.

The core challenge of operating a PEM is maintaining a delicate environmental balance. Its ability to transport protons is entirely dependent on proper hydration, and its physical integrity is sensitive to mechanical and thermal stress, making precise control of its operating conditions non-negotiable.

The Critical Triangle of Operating Conditions

A PEM's performance is not determined by a single variable but by the interplay of temperature, humidity, and pressure. Understanding how each impacts the membrane is fundamental to successfully operating any electrochemical device that uses one.

Temperature Control

The ideal operating temperature for a typical PEM is between 60-80°C. This range represents a balance between reaction kinetics and membrane stability.

Operating outside this window, even slightly, can cause significant issues. Lower temperatures reduce proton conductivity, while excessively high temperatures can accelerate the aging and degradation of the polymer material, shortening its lifespan.

Humidity Management (The Water Balance)

Humidity is arguably the most critical variable to control. The sulfonic acid groups within the polymer membrane require water molecules to effectively transport protons.

The target relative humidity is generally between 30%-80%. This is a delicate balancing act:

- Too Dry: If the membrane dries out, its proton conductivity plummets, effectively halting the electrochemical reaction.

- Too Wet: Conversely, excessive water can flood the electrodes, blocking the pathways for reactant gases to reach the catalyst sites.

Proper hydration is typically maintained by using a humidifier to carefully control the humidity of the reactant gases entering the system.

Pressure and Current Density

High pressure and high current density are forms of mechanical and electrical stress that accelerate the membrane's aging process.

While pushing for higher performance might seem desirable, prolonged operation under these strenuous conditions will significantly reduce the membrane's operational life. Furthermore, sudden changes in pressure or current during startup and shutdown can cause physical shock, leading to cracks or tears in the delicate membrane.

Protecting the Membrane from External Threats

Even with perfect operating conditions, external factors can compromise the membrane. A holistic approach to system health is essential for protecting this central component.

The Danger of Contamination

A PEM must be shielded from contaminants like heavy metal ions and organic compounds.

These substances can adsorb onto the membrane's surface or enter its structure, physically blocking the proton channels. This contamination degrades performance and can be very difficult to reverse.

The Importance of System Integrity

The membrane does not operate in isolation. Regularly checking related components, such as the electrodes and flow field plates, is crucial.

A malfunctioning or degraded component elsewhere in the system can negatively impact the membrane, creating localized hot spots, uneven pressure distribution, or introducing contaminants.

Understanding the Trade-offs and Risks

Managing a PEM involves navigating inherent trade-offs. Recognizing these conflicts is key to making informed operational decisions.

The Dry-Out vs. Flooding Dilemma

The constant need to manage water content is the most common operational challenge. Optimizing for gas diffusion (favoring lower humidity) is in direct conflict with optimizing for proton conductivity (favoring higher humidity), requiring a carefully maintained equilibrium.

Performance vs. Lifespan

There is a direct trade-off between pushing for maximum immediate output and ensuring long-term durability. Operating at the upper limits of temperature and current density will yield higher performance but will invariably shorten the membrane's service life.

Physical vs. Chemical Degradation

Membrane failure can occur through two primary pathways. Physical degradation results from mechanical stress, such as pressure cycles and shock. Chemical degradation is driven by high temperatures and exposure to contaminants. Both must be managed to ensure reliability.

Key Considerations for Your Application

Before and after operation, proper handling is just as important as controlling the conditions during use. This includes pre-treatment with solutions like dilute sulfuric acid, careful inspection for defects, and gentle cleaning with deionized water after disassembly.

- If your primary focus is maximum performance: You will need to operate at the higher end of the optimal temperature and humidity range, while accepting the consequence of a shorter operational lifespan.

- If your primary focus is long-term stability: Operate conservatively in the middle of the recommended temperature, humidity, and pressure ranges, and avoid aggressive current ramps or high-density operation.

- If you are diagnosing poor performance: Your first step should be to investigate the water balance for signs of membrane dry-out or electrode flooding, as this is the most common failure mode.

Mastering control over these environmental conditions is the definitive key to unlocking the full potential and reliability of proton exchange membrane technology.

Summary Table:

| Operating Condition | Ideal Range | Key Impact |

|---|---|---|

| Temperature | 60-80°C | Balances reaction kinetics & membrane stability |

| Humidity | 30-80% RH | Critical for proton conductivity & prevents dry-out/flooding |

| Pressure/Current Density | Controlled, stable | Prevents mechanical stress & physical degradation |

Optimize your PEM system's performance and lifespan with KINTEK.

As specialists in lab equipment and consumables, we provide the precise instruments and expert support needed to maintain the critical balance of temperature, humidity, and pressure for your proton exchange membranes. Ensure reliable results and protect your investment.

Contact our experts today to discuss your specific application needs and discover how KINTEK solutions can enhance your laboratory's efficiency and reliability.

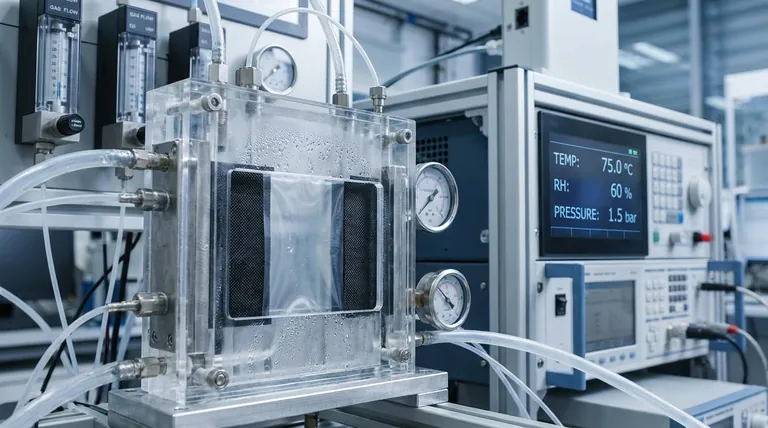

Visual Guide

Related Products

- Proton Exchange Membrane for Batteries Lab Applications

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- Polyethylene Separator for Lithium Battery

- Anion Exchange Membrane for Laboratory Use

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

People Also Ask

- What are the primary roles of a Proton Exchange Membrane (PEM) in a dual-chamber MFC? Enhance Your Fuel Cell Efficiency

- What initial steps are required before using a new proton exchange membrane? Ensure Peak Performance and Longevity

- What should be done if a proton exchange membrane is found to be contaminated or damaged? Restore Performance or Replace for Safety

- How should a proton exchange membrane be installed? A Guide to Flawless Assembly for Peak Performance

- What is the function of a PEM in an MFC? Optimize Proton Migration & Power Efficiency