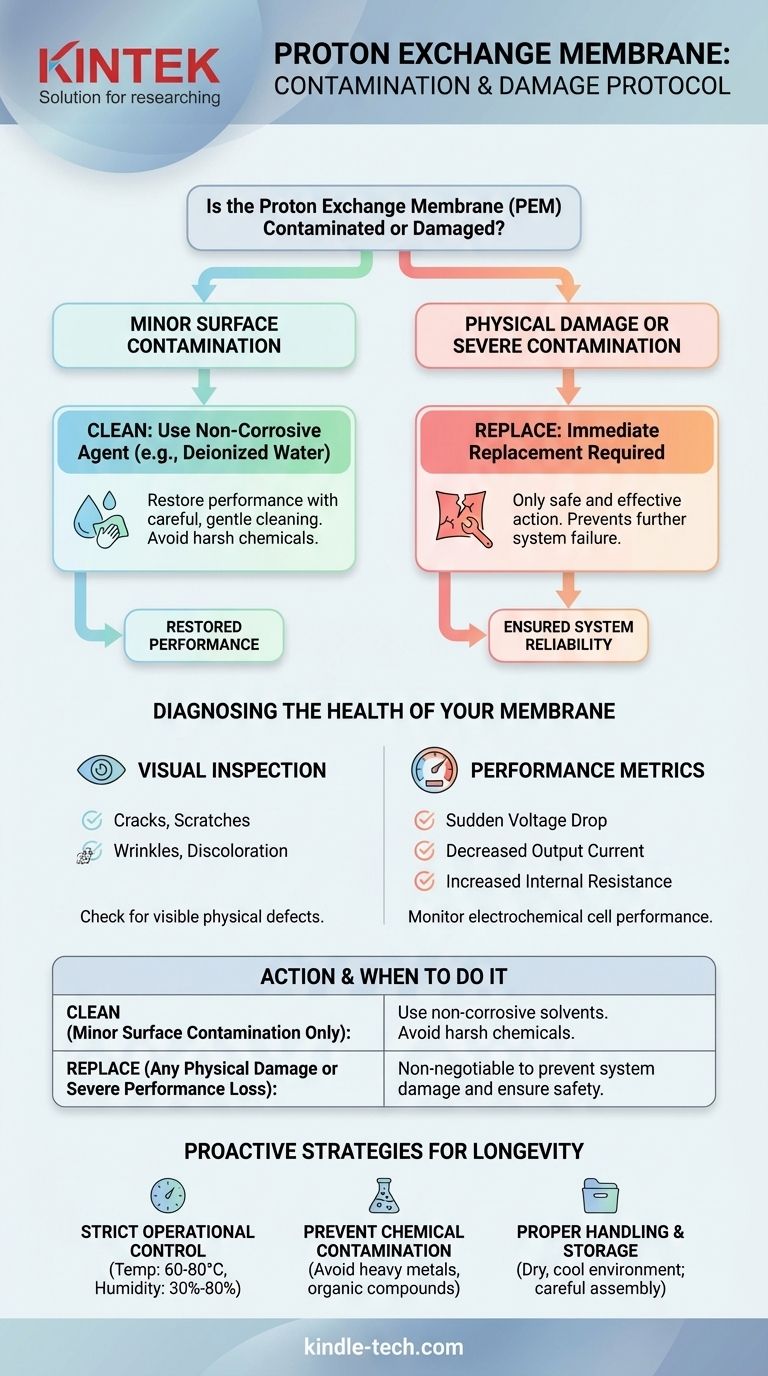

If a proton exchange membrane (PEM) is found to be contaminated or damaged, your immediate action is to either clean it with a non-corrosive agent or replace it entirely. For minor surface contamination, a careful cleaning process can restore performance. However, for any form of physical damage or severe contamination, immediate replacement is the only safe and effective course of action.

The decision to clean or replace a PEM is just the final step. A more robust strategy involves a cycle of proactive monitoring to detect issues early, careful handling to prevent damage, and precise operational control to minimize contamination and stress on the membrane.

Diagnosing the Health of Your Membrane

Before you can decide on a course of action, you must accurately assess the membrane's condition. This involves both visual checks and performance monitoring.

Visual Inspection: The First Line of Defense

A direct visual inspection is the simplest diagnostic tool. Before installation and after careful disassembly, check the membrane's surface.

Look for any defects such as cracks, scratches, wrinkles, or discoloration. The presence of any physical imperfections is a clear indicator that the membrane's structural integrity is compromised and it should be replaced.

Performance Metrics: The Quantitative Indicators

The most reliable way to monitor membrane health during operation is by tracking the electrochemical cell's performance.

A sudden drop in open-circuit voltage, a decrease in output current, or a rise in internal resistance all point to a potential problem with the membrane, such as contamination blocking proton channels.

The Core Decision: To Clean or To Replace?

Once an issue is identified, the choice between cleaning and replacement depends entirely on the nature and severity of the problem.

When to Clean a Contaminated Membrane

Cleaning is a viable option only for minor surface contamination. This includes surface impurities or reaction products that have not permanently bonded with or damaged the membrane structure.

Use a suitable, non-corrosive solvent like deionized water to gently clean the surface. This can effectively remove contaminants that are simply adsorbed onto the membrane.

When Replacement is Non-Negotiable

Replacement is the only correct action if you observe severe damage. This includes any visible cracks, deep scratches, or significant discoloration.

Furthermore, if performance degradation is severe and cannot be reversed by a gentle cleaning cycle, it indicates deeper contamination or structural aging. In this case, the membrane must be replaced immediately.

Understanding the Pitfalls

Making the wrong choice can lead to further system damage or unreliable performance. It is critical to understand the risks involved.

The Risk of Improper Cleaning

Attempting to clean a membrane with strong oxidizing agents, organic solvents, or other corrosive chemicals can cause irreversible damage to its polymer structure. This will permanently degrade its performance and mechanical strength.

The Hidden Costs of Delaying Replacement

Continuing to operate a system with a damaged membrane is a significant risk. It can lead to poor efficiency, reactant crossover, and potentially cause damage to more expensive components like the catalyst layers or electrodes, resulting in a much more costly failure.

Proactive Strategies for Membrane Longevity

The most effective approach is to prevent damage and contamination from occurring in the first place through diligent operational and handling procedures.

Strict Control of Operating Conditions

A PEM is highly sensitive to its environment. Maintain the operating temperature (typically 60-80°C) and relative humidity (30%-80%) within the recommended ranges.

Avoid prolonged operation at high current densities or pressures, which can accelerate aging. Implement gradual changes during startup and shutdown to prevent mechanical shock.

Preventing Chemical Contamination

Protect the membrane from contact with contaminants like heavy metal ions and organic compounds. These substances can block the proton channels and poison the catalyst, severely degrading performance.

Proper Handling and Storage Protocols

Always handle the membrane carefully, especially during assembly and disassembly, avoiding any forceful pulling.

Store membranes in a dry, cool, well-ventilated environment, sealed in their original packaging. Keep them away from direct sunlight, high temperatures, and chemical fumes to prevent degradation.

Making the Right Choice for Your System

Your decision should be guided by your ultimate goal for the system's performance and reliability.

- If your primary focus is restoring immediate performance from minor contamination: Attempt a gentle cleaning cycle using deionized water or another specified non-corrosive agent.

- If your primary focus is ensuring long-term system reliability and you detect any physical damage: Replace the membrane without hesitation to prevent cascading component failures.

- If your primary focus is maximizing the lifespan of all membranes in your facility: Implement a strict preventative maintenance program focused on controlling operating conditions and monitoring system health.

Ultimately, treating your proton exchange membrane as a critical, sensitive component through diligent monitoring and care is the key to reliable system performance.

Summary Table:

| Action | When to Do It | Key Considerations |

|---|---|---|

| Clean | Minor surface contamination only | Use non-corrosive solvents like deionized water. Avoid harsh chemicals. |

| Replace | Any physical damage (cracks, scratches) or severe performance loss | Non-negotiable to prevent system damage and ensure safety. |

Ensure your lab's fuel cell research and development remains on track with reliable PEM solutions. A contaminated or damaged proton exchange membrane can halt your progress and risk damaging other sensitive components. KINTEK specializes in high-quality lab equipment and consumables, providing the precise materials and expert support your laboratory needs for consistent, reliable results. Don't let membrane issues compromise your work—contact our experts today to discuss your specific requirements and keep your systems running at peak performance.

Visual Guide

Related Products

- Proton Exchange Membrane for Batteries Lab Applications

- Custom Ion Conductivity Test Fixtures for Fuel Cell Research

- Polyethylene Separator for Lithium Battery

- Anion Exchange Membrane for Laboratory Use

- Multifunctional Electrolytic Electrochemical Cell Water Bath Single Layer Double Layer

People Also Ask

- What initial steps are required before using a new proton exchange membrane? Ensure Peak Performance and Longevity

- What is the function of perfluorinated sulfonic acid proton exchange membranes in the preparation of biomimetic sensors?

- What are the procedures for handling a proton exchange membrane after use? Ensure Longevity and Performance

- How should a proton exchange membrane be installed? A Guide to Flawless Assembly for Peak Performance

- What is a proton exchange membrane? The Selective Heart of Hydrogen Energy Systems