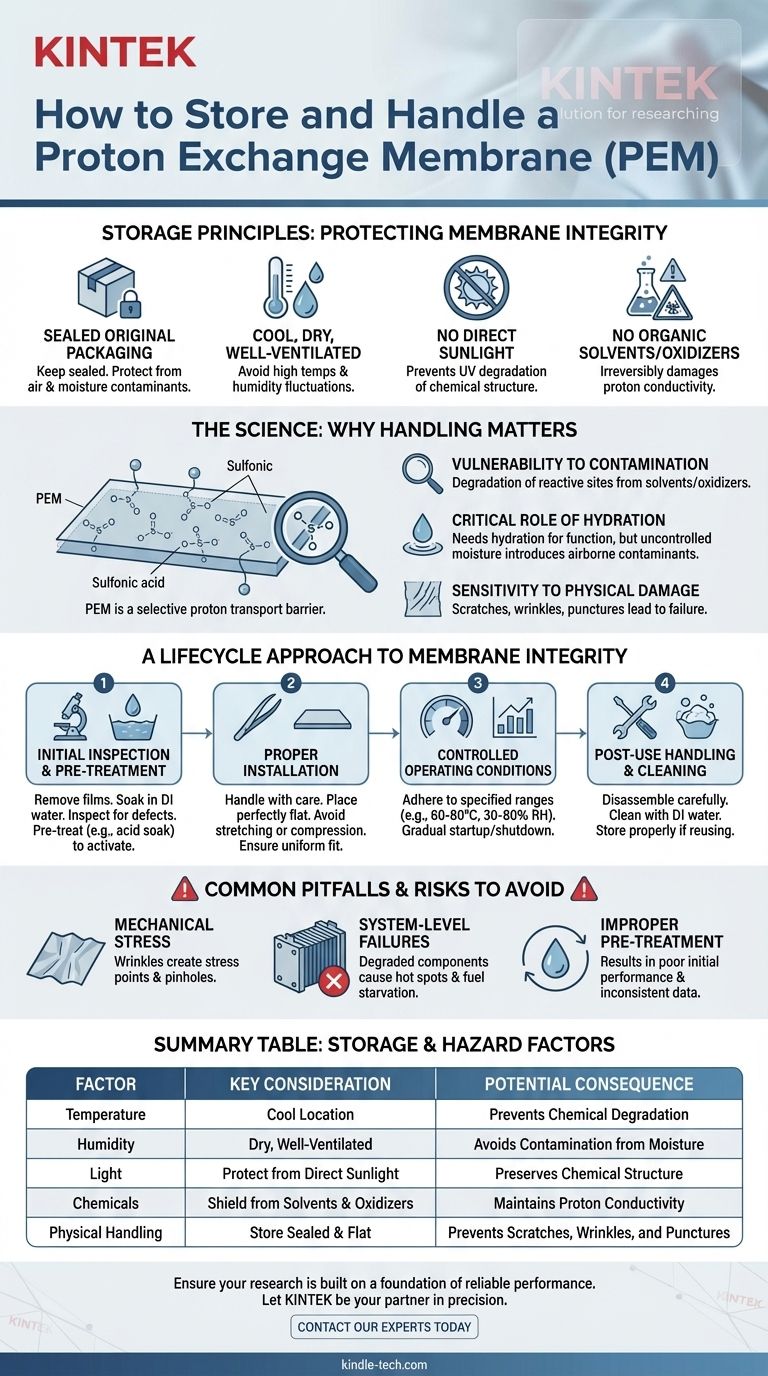

To properly store a proton exchange membrane (PEM), you must keep it sealed in its original packaging in a cool, dry, and well-ventilated location. It is critical to protect the membrane from direct sunlight, high temperatures, organic solvents, and strong oxidizing agents, as these can irreversibly damage its chemical structure and performance.

A proton exchange membrane's high performance is a direct result of its sensitive chemical and physical structure. Therefore, proper storage is not just a recommendation but the first step in a disciplined handling process that extends through the membrane's entire lifecycle, from initial inspection to post-use cleaning.

The Science of PEMs: Why Handling Matters

A proton exchange membrane is a sophisticated polymer film, typically containing sulfonic acid groups, designed for a single, critical task: selectively transporting protons. This unique function makes it the heart of devices like fuel cells and electrolyzers.

Vulnerability to Chemical Contamination

The acidic groups that enable proton transport are also reactive sites. Exposure to organic solvents or strong oxidizing agents can degrade these sites, permanently reducing the membrane's proton conductivity and overall efficiency.

The Critical Role of Hydration

While PEMs must be hydrated to function, uncontrolled moisture absorption during storage can introduce contaminants from the air. Storing the membrane in its sealed packaging prevents this, maintaining a pristine state until it is ready for pre-treatment and use.

Sensitivity to Physical Damage

A PEM is a thin film. Scratches, wrinkles, or punctures create weak spots that can lead to gas crossover or catastrophic failure under operating pressure. Every step of handling must prioritize maintaining its physical integrity.

A Lifecycle Approach to Membrane Integrity

Preserving a membrane goes far beyond simple storage. Adopting a meticulous process for every stage is essential for reliable and repeatable results.

Initial Inspection and Pre-Treatment

Before use, remove the protective films, often by soaking the membrane in pure deionized water for about ten minutes. Carefully inspect the surface for any defects, scratches, or wrinkles. A flawed membrane should not be used.

Most applications also require a pre-treatment step, such as soaking in dilute sulfuric acid, to remove manufacturing impurities and fully activate the proton-conducting channels.

Proper Installation Technique

Handle the membrane with care, ensuring its surface remains clean. It must be placed perfectly flat within the electrochemical cell hardware.

Avoid any stretching or compression, as this introduces internal stress. A tight, uniform fit between the membrane and the electrodes is crucial to minimize contact resistance and ensure even current distribution.

Controlled Operating Conditions

Adhere strictly to the manufacturer's specified operating conditions. Typical ranges are 60-80°C and 30%-80% relative humidity. Deviating from these parameters can harm proton conductivity and accelerate aging.

Gradual changes in pressure and current during startup and shutdown are also vital to prevent mechanical shock to the membrane assembly.

Post-Use Handling and Cleaning

After an experiment, disassemble the cell carefully without forcefully pulling on the membrane. Clean its surface with deionized water to remove any reaction byproducts.

If you plan to reuse the membrane, ensure it is properly cleaned and then stored according to the initial storage guidelines. Its performance can be re-assessed by measuring properties like proton conductivity.

Common Pitfalls and Risks to Avoid

Objectively understanding the risks is key to mitigating them. Improper handling at any stage can compromise your results and your investment in materials.

The Risk of Mechanical Stress

Wrinkles or stretching during installation are not minor issues. These deformities create localized stress points and high-resistance spots that can lead to pinhole formation, reactant crossover, and premature cell failure.

The Danger of System-Level Failures

The membrane's health is dependent on the entire system. Degraded electrodes or blocked flow field plates can cause non-uniform conditions across the membrane surface, leading to hot spots or fuel starvation that can permanently damage it. Regular system maintenance is non-negotiable.

The Impact of Improper Pre-Treatment

Skipping or incorrectly performing the pre-treatment step can leave the membrane with impurities or in a sub-optimal state of hydration. This will result in poor initial performance and inconsistent data, masking the true potential of your electrochemical cell.

Making the Right Choice for Your Goal

Your handling strategy should align with your specific objective. Use this checklist to guide your actions.

- If your primary focus is long-term archival of new membranes: Keep them in their original sealed packaging in a controlled, cool, and dry environment away from any chemical vapors.

- If your primary focus is preparing a membrane for a new experiment: Follow a rigorous protocol of inspection, cleaning, pre-treatment, and careful installation to establish a reliable performance baseline.

- If your primary focus is reusing a membrane after an experiment: Meticulously clean it with deionized water, inspect it for degradation, and return it to proper storage conditions immediately.

Ultimately, treating your proton exchange membrane with meticulous care at every step is the only way to protect its integrity and ensure the validity of your work.

Summary Table:

| Storage/Hazard Factor | Key Consideration | Potential Consequence |

|---|---|---|

| Temperature | Store in a cool location | Prevents chemical degradation |

| Humidity | Keep in a dry, well-ventilated area | Avoids contamination from moisture |

| Light | Protect from direct sunlight | Preserves chemical structure |

| Chemicals | Shield from solvents & oxidizers | Maintains proton conductivity |

| Physical Handling | Store sealed and flat | Prevents scratches, wrinkles, and punctures |

Ensure your research is built on a foundation of reliable performance. Proper handling of sensitive components like proton exchange membranes is critical for valid, repeatable results. At KINTEK, we specialize in providing the high-quality lab equipment and consumables that your electrochemical research demands. From fuel cell test stations to precision handling tools, our products are designed to support meticulous protocols and protect your valuable materials.

Let KINTEK be your partner in precision. Contact our experts today to discuss how our solutions can help you achieve superior results and extend the lifecycle of your critical components.

Visual Guide

Related Products

- Proton Exchange Membrane for Batteries Lab Applications

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- Anion Exchange Membrane for Laboratory Use

- Polyethylene Separator for Lithium Battery

- Multifunctional Electrolytic Electrochemical Cell Water Bath Single Layer Double Layer

People Also Ask

- How should a proton exchange membrane be installed? A Guide to Flawless Assembly for Peak Performance

- What should be done if a proton exchange membrane is found to be contaminated or damaged? Restore Performance or Replace for Safety

- What operating conditions must be controlled when using a proton exchange membrane? Master Temperature, Humidity, and Pressure

- What is the function of a PEM in an MFC? Optimize Proton Migration & Power Efficiency

- What are the procedures for handling a proton exchange membrane after use? Ensure Longevity and Performance