Properly handling a proton exchange membrane (PEM) after use involves a careful sequence of disassembly, cleaning, and storage. The membrane must be removed gently without stretching, cleaned with a solvent like deionized water to remove impurities, and then stored in a sealed, cool, and dry environment to prevent contamination and preserve its structural integrity for future use or analysis.

A proton exchange membrane is the delicate heart of an electrochemical cell. Its post-use condition is not just a result of how you store it, but a direct reflection of how it was installed, operated, and disassembled. Proper handling throughout its entire lifecycle is the key to its longevity and performance.

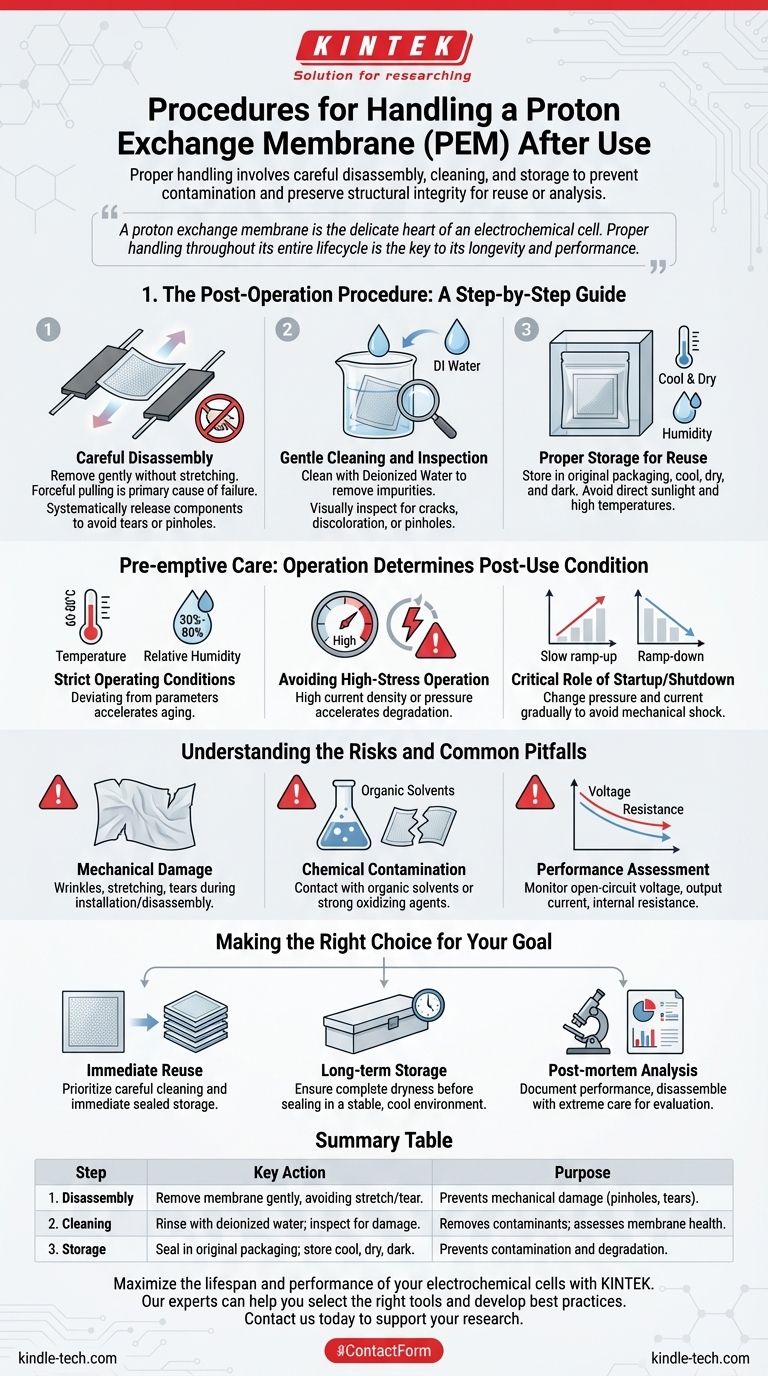

The Post-Operation Procedure: A Step-by-Step Guide

Handling a PEM after operation requires precision and care to avoid irreversible damage. Follow these steps methodically.

Step 1: Careful Disassembly

The first step is to remove the membrane from the electrochemical cell assembly. This process is critical, as mechanical stress is a primary cause of failure.

Forceful pulling or stretching must be avoided. The membrane is often adhered to the electrodes or gaskets, so disassemble the cell components systematically to release the membrane without causing tears or pinholes.

Step 2: Gentle Cleaning and Inspection

Once removed, the membrane surface may have residual reaction products or impurities.

Clean the membrane with a suitable, non-aggressive solvent. Deionized water is the standard choice for this task. This removes surface contaminants that could interfere with future performance.

After cleaning, perform a visual inspection. Look for any signs of physical damage, such as cracks, discoloration, or pinholes, which indicate degradation.

Step 3: Proper Storage for Reuse

If the membrane is intended for reuse, storage conditions are paramount.

The membrane must be stored in a cool, dry, and well-ventilated environment, shielded from direct sunlight and high temperatures. To prevent moisture absorption and contamination, keep it sealed in its original packaging or a similar inert container.

Pre-emptive Care: How Operation Determines Post-Use Condition

The state of the membrane after use is determined long before disassembly. Its operational life dictates its health.

The Importance of Strict Operating Conditions

A PEM operates optimally within a narrow window. Deviating from these parameters accelerates aging and damage.

The typical operating temperature is 60-80°C, with relative humidity between 30%-80%. Conditions outside this range can degrade proton conductivity and shorten the membrane's lifespan.

Avoiding High-Stress Operation

Prolonged operation under high current density or high pressure should be avoided. These conditions accelerate mechanical and chemical degradation, leading to premature failure.

The Critical Role of Startup and Shutdown

Mechanical shock is a significant threat. During startup and shutdown, pressure and current must be changed gradually and systematically. Abrupt changes can create pressure differentials that physically damage the membrane.

Understanding the Risks and Common Pitfalls

Mishandling at any stage can lead to permanent damage. Understanding these failure modes is crucial for prevention.

Risk 1: Mechanical Damage

Mechanical stress is the most common cause of failure. This includes wrinkles, stretching, or compression during installation, as well as tears during disassembly.

A membrane must be installed perfectly flat between the electrodes to ensure a tight fit, minimize contact resistance, and avoid creating internal stress points that can later become cracks.

Risk 2: Chemical Contamination and Degradation

The membrane's chemical structure is sensitive. Contact with organic solvents or strong oxidizing agents must be strictly avoided, as they can irreversibly damage the polymer and compromise its performance.

Likewise, ensure that related system components, like electrodes and flow field plates, are clean and functioning correctly, as they can be a source of contaminants that harm the membrane.

Risk 3: Performance Assessment and Monitoring

To understand the membrane's health, you must monitor it. Periodically check the cell's open-circuit voltage, output current, and internal resistance. A sudden drop in performance often points to membrane degradation.

This in-situ monitoring, combined with post-use visual inspection and property measurements (like proton conductivity), gives you a complete picture of the membrane's condition.

Making the Right Choice for Your Goal

Your handling strategy depends on your objective for the membrane after its initial use.

- If your primary focus is immediate reuse: Prioritize careful cleaning with deionized water and immediate storage in a sealed, dry container to prevent any atmospheric contamination before reinstallation.

- If your primary focus is long-term storage: Ensure the membrane is completely dry before sealing it in its packaging and storing it in a stable, cool environment away from any chemical vapors or sunlight.

- If your primary focus is post-mortem analysis: Document the cell's performance data right before shutdown, then disassemble with extreme care to preserve the membrane's state for microscopic or electrochemical evaluation.

Ultimately, treating the proton exchange membrane as a high-precision component at every stage of its life is the only way to ensure its reliability and value.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1. Disassembly | Remove membrane gently, avoiding stretch/tear. | Prevents mechanical damage (pinholes, tears). |

| 2. Cleaning | Rinse with deionized water; inspect for damage. | Removes contaminants; assesses membrane health. |

| 3. Storage | Seal in original packaging; store cool, dry, dark. | Prevents contamination and degradation. |

Maximize the lifespan and performance of your electrochemical cells with KINTEK.

Proper handling of delicate components like proton exchange membranes is critical for reliable results. KINTEK specializes in providing the high-precision lab equipment and consumables your laboratory needs for optimal PEM fuel cell or electrolyzer operation and maintenance.

Our experts can help you select the right tools and develop best practices for your specific application. Contact us today to discuss how we can support your research and ensure the integrity of your materials.

Visual Guide

Related Products

- Proton Exchange Membrane for Batteries Lab Applications

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- FS Electrochemical Hydrogen Fuel Cells for Diverse Applications

- Customizable Fuel Cell Stack Components for Diverse Applications

- Electrolytic Electrochemical Cell with Five-Port

People Also Ask

- Why is humidity control critical for PEM maintenance? Achieve Peak Performance and Longevity

- What is the function of perfluorinated sulfonic acid proton exchange membranes in the preparation of biomimetic sensors?

- What initial steps are required before using a new proton exchange membrane? Ensure Peak Performance and Longevity

- What operating conditions must be controlled when using a proton exchange membrane? Master Temperature, Humidity, and Pressure

- What should be done if a proton exchange membrane is found to be contaminated or damaged? Restore Performance or Replace for Safety