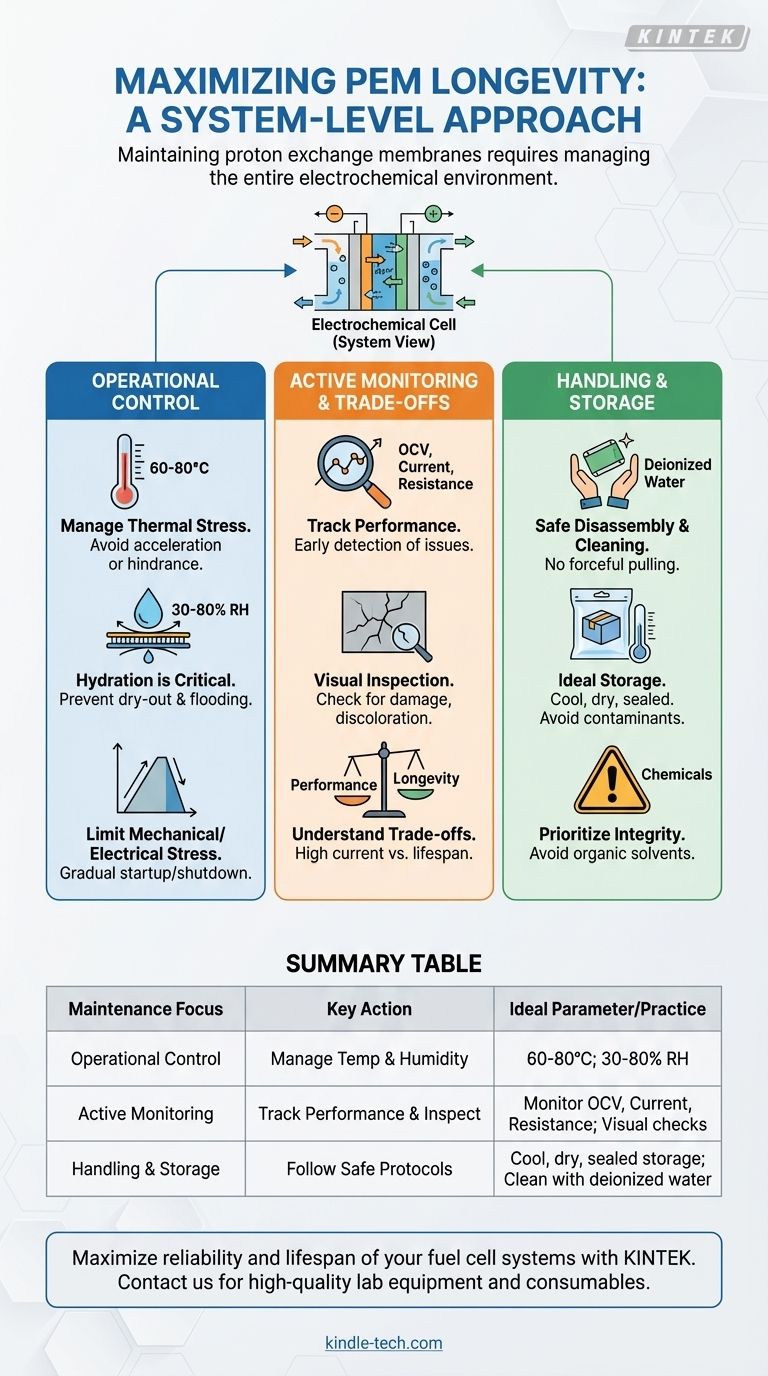

At its core, maintaining the longevity of a proton exchange membrane (PEM) goes beyond the membrane itself. It requires a system-level approach focused on strict operational control, diligent environmental monitoring, and proper physical handling. The health of the entire electrochemical cell—from electrodes to flow fields—directly dictates the stress placed upon the membrane and, consequently, its useful lifespan.

A proton exchange membrane does not fail in isolation. Its degradation is almost always a symptom of instability within the broader system. Therefore, the most effective maintenance strategy is to manage the membrane's operating environment, not just the component itself.

The Foundation: Strict Operational Control

The daily operating conditions are the single greatest factor influencing membrane degradation. Maintaining a stable environment is not just a best practice; it is a fundamental requirement for longevity.

Managing Thermal Stress

The ideal operating temperature for most PEMs is between 60-80°C. Exceeding this range can accelerate chemical degradation pathways, while operating below it can hinder proton conductivity and overall performance.

The Critical Role of Hydration

Proper hydration is a delicate balance. The membrane requires sufficient water to facilitate proton transport, but excessive moisture can flood the electrodes, blocking reactant gas flow.

This is why humidity control is paramount. A relative humidity between 30% and 80%, typically managed by humidifying the reactant gas streams, is essential. A membrane that is too dry will have poor conductivity, while one that is too wet will cause system failure via flooding.

Limiting Mechanical and Electrical Stress

Sudden changes in pressure or current create physical and electrical shocks that can damage the membrane's delicate structure. Implement gradual startup and shutdown procedures to ramp pressure and current smoothly.

Furthermore, avoid prolonged operation at very high current densities. While this may produce more power, it significantly accelerates aging and reduces the overall lifespan of the membrane.

Active Monitoring: Your Early Warning System

You cannot manage what you do not measure. Regular monitoring provides the data needed to detect subtle degradation and intervene before a catastrophic failure occurs.

Tracking Electrochemical Performance

Periodically measure the cell's key performance indicators. A drop in the open-circuit voltage (OCV), a decrease in output current, or an increase in internal resistance all signal potential issues with the membrane or surrounding components.

The Importance of Visual Inspection

During scheduled maintenance or disassembly, conduct a visual inspection of the membrane surface. Look for any signs of physical damage, such as cracks, pinholes, or discoloration. These are clear indicators of mechanical or chemical stress.

Understanding the Trade-offs

Achieving maximum longevity requires balancing competing operational demands. Understanding these trade-offs is key to making informed decisions.

Performance vs. Longevity

There is an inherent trade-off between peak power output and lifespan. Operating at a high current density extracts maximum performance but also accelerates membrane degradation. For applications requiring maximum reliability, operating at a more conservative current density is advisable.

The Hydration Dilemma

The optimal humidity for the membrane's proton conductivity may not be optimal for the gas diffusion layer of the electrodes. Over-humidifying to benefit the membrane can lead to electrode flooding, which cripples performance. This balancing act is a central challenge in fuel cell system design and operation.

The Ripple Effect of Component Failure

The membrane is often the victim, not the culprit. A degrading electrode or a corroding flow field plate can release contaminants or create localized hot spots that will quickly destroy an otherwise healthy membrane. This is why checking the health of all system components is a critical part of membrane maintenance.

Proper Handling and Storage: Preserving Membrane Integrity

The membrane's life can be compromised even when it is not in operation. Proper handling and storage protocols are non-negotiable.

Safe Disassembly and Cleaning

When disassembling the cell, never forcefully pull or stretch the membrane. After removal, gently clean its surface with a suitable solvent like deionized water to remove impurities and residual reaction products.

Creating the Ideal Storage Environment

Store the membrane in a cool, dry, and well-ventilated area away from direct sunlight. It should remain in a sealed package to prevent contamination and moisture absorption. Crucially, avoid any contact with organic solvents or strong oxidizing agents, as they can irreversibly damage the membrane's polymer structure.

Prioritizing Your Maintenance Strategy

Your specific goals will determine your maintenance priorities.

- If your primary focus is maximizing operational lifespan: Prioritize stable, conservative operating conditions (temperature, pressure, current) and diligent performance monitoring above all else.

- If your primary focus is peak performance output: Accept the trade-off of a shorter lifespan and focus intensely on precise hydration control to prevent immediate failure from electrode flooding.

- If you are storing membranes long-term: Adhere strictly to sealed, climate-controlled storage protocols to prevent contamination and chemical degradation before the membrane is ever used.

By treating the membrane as the heart of a complex system, you can proactively manage its environment to ensure maximum reliability and longevity.

Summary Table:

| Maintenance Focus | Key Action | Ideal Parameter / Practice |

|---|---|---|

| Operational Control | Manage Temperature & Humidity | 60-80°C; 30-80% Relative Humidity |

| Active Monitoring | Track Performance & Inspect | Monitor OCV, Current, Resistance; Visual checks for damage |

| Handling & Storage | Follow Safe Protocols | Cool, dry, sealed storage; Clean with deionized water |

Maximize the reliability and lifespan of your fuel cell systems with KINTEK.

Your proton exchange membrane is a critical component, and its performance depends on the entire system. KINTEK specializes in providing high-quality lab equipment and consumables essential for maintaining optimal PEM operating conditions—from precise humidity control systems to monitoring tools.

Let our expertise help you implement a robust, system-level maintenance strategy. Contact our team today to discuss how our solutions can support your laboratory's specific needs and ensure peak performance for your electrochemical applications.

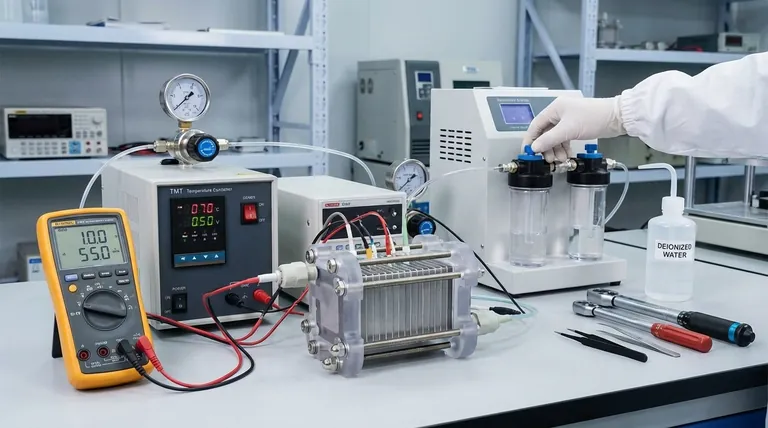

Visual Guide

Related Products

- Customizable Fuel Cell Stack Components for Diverse Applications

- FS Electrochemical Hydrogen Fuel Cells for Diverse Applications

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- PTFE Electrolytic Cell Electrochemical Cell Corrosion-Resistant Sealed and Non-Sealed

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

People Also Ask

- How should carbon paper used in a fuel cell be maintained? Prevent PTFE Degradation for Peak Performance

- What is an electrolysis cell and what are its primary applications? Unlocking Chemical Transformations with Electricity

- What is a common application for proton exchange membranes in laboratory setups? Ensuring Precise Electrochemical Analysis

- What is a proton exchange membrane? The Selective Heart of Hydrogen Energy Systems

- What criteria are used during the visual inspection of electrodes? Essential Quality Assessment for Your Lab