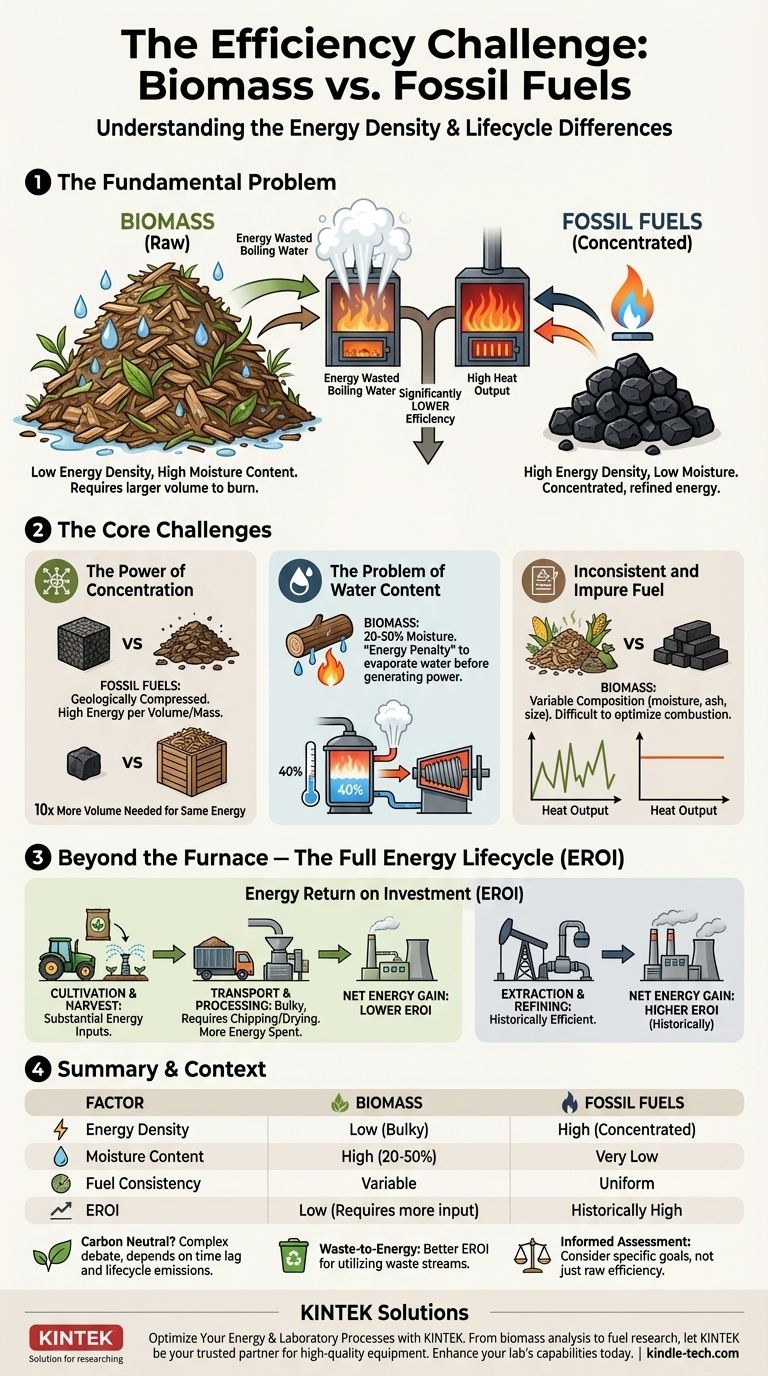

At a fundamental level, biomass energy is less efficient than fossil fuels because its raw material has a much lower energy density and a higher moisture content. This means you must burn a significantly larger volume of biomass (like wood chips or switchgrass) to produce the same amount of heat as a smaller amount of coal or natural gas. Furthermore, a portion of the biomass's energy is wasted simply boiling off its own internal water before it can generate usable power.

The core issue isn't just about the power plant; it's a system-wide inefficiency. Biomass requires immense energy inputs for cultivation, transportation, and processing, all to prepare a fuel that is fundamentally less concentrated than the ancient, geologically compressed energy found in fossil fuels.

The Core Challenge: Fuel Density and Quality

The disparity in efficiency begins with the physical nature of the fuel itself. Fossil fuels have undergone millions of years of geologic heat and pressure, a process that concentrates carbon and removes impurities.

The Power of Concentration

Fossil fuels are, in essence, ancient biomass that has been naturally refined. This process dramatically increases their energy density, which is the amount of energy stored in a given volume or mass.

A lump of coal or a cubic foot of natural gas contains a vast amount of concentrated chemical energy. To get the same energy from fresh biomass, you need a much larger physical quantity, creating logistical and handling challenges from the start.

The Problem of Water Content

Fresh biomass contains a significant amount of water—often 20% to 50% by weight. When this fuel enters a boiler, the first thing that must happen is that this water is boiled away into steam.

This process consumes a substantial amount of the fuel's own energy before any of that energy can be used to heat water for a turbine. This "energy penalty" is a direct hit to the overall thermal efficiency of the power plant.

Inconsistent and Impure Fuel

Unlike the relatively uniform composition of natural gas or graded coal, biomass is highly variable. Wood chips, corn stover, and municipal waste all have different energy contents, moisture levels, and ash contents.

This inconsistency makes it difficult to optimize a power plant's combustion process, often leading to lower operational efficiency compared to a plant burning a predictable and homogenous fossil fuel.

Beyond the Furnace: The Full Energy Lifecycle

A true measure of efficiency goes beyond the power plant and examines the total energy required to produce the fuel in the first place. This concept is known as Energy Return on Investment (EROI).

Energy Return on Investment (EROI)

EROI is a simple ratio: the amount of energy you get out divided by the amount of energy you put in to get it. A high EROI is good; a low EROI is bad.

Fossil fuels have historically had a very high EROI. While this is declining, it remains significantly higher than that of most biomass feedstocks, especially those that must be actively cultivated.

The "Energy In": Cultivation and Harvest

Growing energy crops like switchgrass or corn for ethanol requires substantial energy inputs. This includes the fuel for tractors, the production of fertilizers (often made from natural gas), and energy for irrigation systems.

This agricultural energy expenditure must be "paid back" by the energy produced, which immediately lowers the net efficiency of the entire process.

The "Energy In": Transportation and Processing

Because biomass has low density, it is bulky and expensive to transport. A power plant requires a constant, massive stream of material, meaning trucks or trains are constantly running.

Furthermore, the fuel often must be processed—chipped, ground, and dried into pellets—to make it more uniform and energy-dense. Each of these steps consumes additional energy, further reducing the net energy gain.

Understanding the Trade-offs

While less efficient in a direct comparison, viewing biomass solely through this lens misses the complete picture. The context in which it's used is critical.

The "Carbon Neutral" Debate

Biomass is often touted as carbon-neutral because the carbon released when it's burned was recently absorbed from the atmosphere during the plant's growth.

However, this is an oversimplification. There is a "carbon debt" and a time lag. Burning a forest's worth of wood releases carbon instantly, but it can take decades for a new forest to reabsorb an equivalent amount. The full lifecycle, including transportation and processing emissions, also complicates the carbon-neutral claim.

The Niche of Waste-to-Energy

The efficiency calculation changes dramatically when the biomass is a waste product. Using sawdust from a lumber mill, agricultural residue, or manure for biogas generation is a different proposition.

In these cases, you are solving a waste disposal problem and generating energy simultaneously. The EROI is much more favorable because you are not spending energy to specifically grow the fuel.

Making an Informed Assessment of Biomass

Evaluating biomass requires moving beyond a simple "efficient vs. inefficient" label and considering the specific goal and application.

- If your primary focus is maximizing raw thermal efficiency and energy output: Fossil fuels, particularly natural gas, are technically superior due to their high energy density and low moisture content.

- If your primary focus is utilizing local waste streams and reducing landfill pressure: Biomass can be a highly logical and efficient solution, turning a liability into an asset.

- If your primary focus is creating a scalable, dispatchable, low-carbon energy source: Dedicated crop-based biomass struggles to compete with other technologies due to its low EROI and significant land-use requirements.

Understanding that biomass is a low-density, high-moisture fuel explains its limitations and highlights where it can be applied most effectively.

Summary Table:

| Factor | Biomass | Fossil Fuels |

|---|---|---|

| Energy Density | Low (bulky, requires more volume) | High (concentrated energy) |

| Moisture Content | High (20-50%, wastes energy on evaporation) | Very low |

| Fuel Consistency | Variable (wood chips, waste, crops) | Uniform (graded coal, natural gas) |

| Energy Return on Investment (EROI) | Low (due to cultivation, transport, processing) | Historically high |

Optimize Your Energy and Laboratory Processes with KINTEK

Understanding fuel efficiency is critical, whether you're working with biomass, fossil fuels, or advanced materials. At KINTEK, we specialize in providing high-quality lab equipment and consumables that help researchers and engineers analyze, test, and improve energy systems. From precise thermal processing furnaces to sample preparation tools, our solutions support accurate data collection and process optimization.

If you're involved in energy research, material science, or laboratory testing, let KINTEK be your trusted partner. We serve laboratories worldwide with reliable equipment tailored to your needs.

Contact us today to discuss how we can enhance your lab's capabilities and drive your projects forward.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

People Also Ask

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy