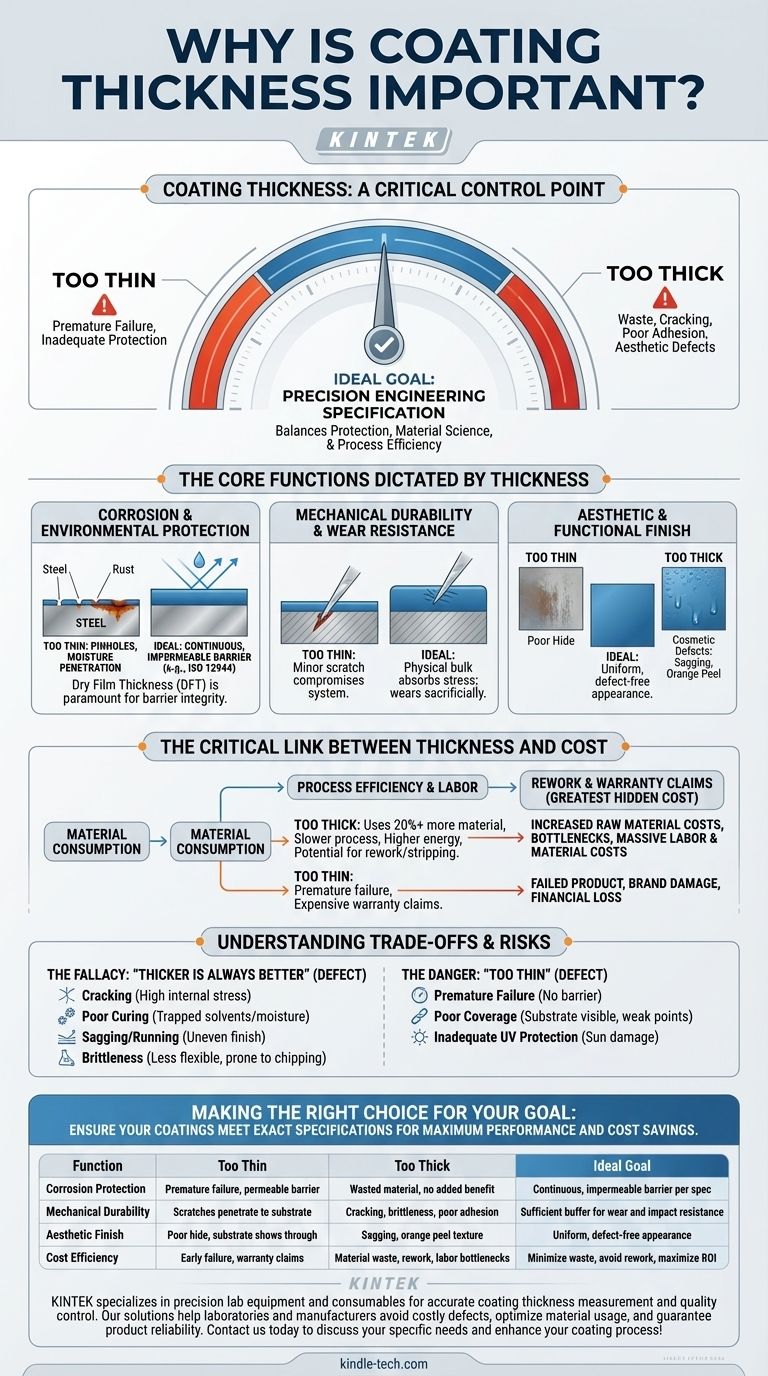

Coating thickness is a critical control point that directly dictates a product's performance, lifespan, and final cost. It is not an arbitrary measurement but a precise engineering specification that balances the need for protection against the realities of material science and process efficiency. Getting it wrong can lead to premature failure or unnecessary expense, while getting it right ensures the product performs exactly as designed.

The core challenge is not simply to apply a coating, but to apply it at the correct thickness. Too thin, and the coating fails to provide its intended protection. Too thick, and you waste material while introducing new risks of cracking, poor adhesion, and aesthetic defects.

The Core Functions Dictated by Thickness

A coating's primary purpose—whether for protection, aesthetics, or function—is achieved only within a specific thickness range. This range is known as the Dry Film Thickness (DFT) and is the most critical measurement for quality control.

Corrosion and Environmental Protection

A primary role for many coatings is to act as a barrier between a substrate (like steel) and a corrosive environment. The thickness of this barrier is paramount.

An insufficient DFT leaves microscopic pinholes or a permeable layer, allowing moisture and chemicals to reach the substrate and initiate corrosion. The coating fails before its expected service life.

Conversely, a properly specified thickness, as defined by standards like ISO 12944, ensures a continuous, impermeable barrier capable of withstanding the intended environment for years.

Mechanical Durability and Wear Resistance

Coatings must often endure abrasion, impact, and scratching. Thickness provides the physical bulk needed to absorb these stresses.

If a coating is too thin, a minor scratch can easily penetrate to the substrate, compromising the entire system. A sufficient DFT provides a buffer, allowing the coating to wear away sacrificially over time without immediate failure.

Aesthetic and Functional Finish

For consumer products and architectural elements, appearance is key. Coating thickness has a direct impact on the final look.

Too thin can result in poor "hide," where the underlying substrate color or profile shows through. Too thick can lead to cosmetic defects like sagging, running on vertical surfaces, or a bumpy "orange peel" texture.

Adhesion and Inter-coat Integrity

Proper adhesion is the foundation of any successful coating system. Applying a coat that is excessively thick can severely compromise this.

When a coating is too thick, the surface can dry while trapping solvents underneath. This can lead to poor curing, a soft underlying film, and eventual delamination or blistering. It also creates internal stresses that can cause the coating to crack and peel away.

The Critical Link Between Thickness and Cost

Beyond performance, thickness is a direct driver of project cost. Controlling it is essential for financial viability.

Material Consumption

Coatings are purchased by the gallon but specified by the micron. Applying a coating 20% thicker than specified means you are using 20% more material than necessary, directly increasing your raw material costs.

Process Efficiency and Labor

Applying excessive thickness often requires extra passes by an applicator or slower line speeds in an automated process. It can also extend curing times, creating production bottlenecks and increasing energy consumption.

Rework and Warranty Claims

This is the greatest hidden cost. A coating applied outside of specification is, by definition, a defect. If it's too thin, it will fail prematurely, leading to expensive warranty claims. If it's too thick, it may require being stripped and reapplied, incurring massive labor and material costs.

Understanding the Trade-offs and Risks

A common but dangerous assumption is that "thicker is always better." An expert understands that the goal is not to maximize thickness, but to hit the specified target.

The Fallacy of "Thicker is Always Better"

Excessive film thickness is just as much a defect as insufficient thickness. It introduces significant risks:

- Cracking: Thick films develop high internal stress as they cure, which can cause them to crack and delaminate, especially under thermal cycling.

- Poor Curing: Solvents or moisture can become trapped, preventing the film from achieving its full hardness and chemical resistance.

- Sagging and Running: Gravity will pull on an overly thick wet film, causing drips and an uneven finish.

- Brittleness: Many coatings become less flexible and more brittle when applied too thickly, making them prone to chipping on impact.

The Danger of "Too Thin"

The risks of applying a coating that is too thin are more obvious but equally critical. These include:

- Premature Failure: The coating cannot provide the required barrier or wear protection.

- Poor Coverage: The substrate is not fully hidden, leading to a poor aesthetic and weak points in the protective barrier.

- Inadequate UV Protection: For exterior coatings, a certain thickness is required to house the UV-blocking additives needed to prevent sun damage.

Making the Right Choice for Your Goal

The correct coating thickness is not a matter of opinion; it is dictated by the manufacturer's data sheet and the project specification. Your goal is to adhere to that specification with precision.

- If your primary focus is maximum corrosion protection: Adhere strictly to the DFT specified for the target environment, and ensure consistent measurement across the entire surface.

- If your primary focus is cost optimization: Invest in applicator training and calibrated measurement gauges to minimize material waste and avoid costly rework from out-of-spec application.

- If your primary focus is aesthetic quality: Follow the manufacturer's recommended thickness precisely to prevent defects like orange peel, sagging, or poor hide that compromise the final appearance.

Ultimately, precise control over coating thickness is not just a quality check; it is a fundamental pillar of product performance, reliability, and profitability.

Summary Table:

| Function | Too Thin | Too Thick | Ideal Goal |

|---|---|---|---|

| Corrosion Protection | Premature failure, permeable barrier | Wasted material, no added benefit | Continuous, impermeable barrier per spec (e.g., ISO 12944) |

| Mechanical Durability | Scratches penetrate to substrate | Cracking, brittleness, poor adhesion | Sufficient buffer for wear and impact resistance |

| Aesthetic Finish | Poor hide, substrate shows through | Sagging, orange peel texture | Uniform, defect-free appearance |

| Cost Efficiency | Early failure, warranty claims | Material waste, rework, labor bottlenecks | Minimize waste, avoid rework, maximize ROI |

Ensure your coatings meet exact specifications for maximum performance and cost savings. KINTEK specializes in precision lab equipment and consumables for accurate coating thickness measurement and quality control. Our solutions help laboratories and manufacturers avoid costly defects, optimize material usage, and guarantee product reliability. Contact us today to discuss your specific needs and enhance your coating process!

Visual Guide

Related Products

- Filter Testing Machine FPV for Dispersion Properties of Polymers and Pigments

- Anti-Cracking Press Mold for Lab Use

- Laboratory CVD Boron Doped Diamond Materials

- Automatic Laboratory Heat Press Machine

- Customizable PEM Electrolysis Cells for Diverse Research Applications

People Also Ask

- What is a filter tester? A Guide to Measuring Filtration Efficiency & Performance

- What is the significance of compression set? Predict Material Failure and Ensure Long-Term Reliability

- Is there a battery tester for lithium batteries? Unlock Accurate Health Diagnostics Beyond Voltage

- How do you test a lithium battery to see if it's good? A Guide to Measuring Voltage, Capacity & Health

- What are the advantages of using PTFE filters for ionic component analysis? Ensure Accurate Sample Quantification