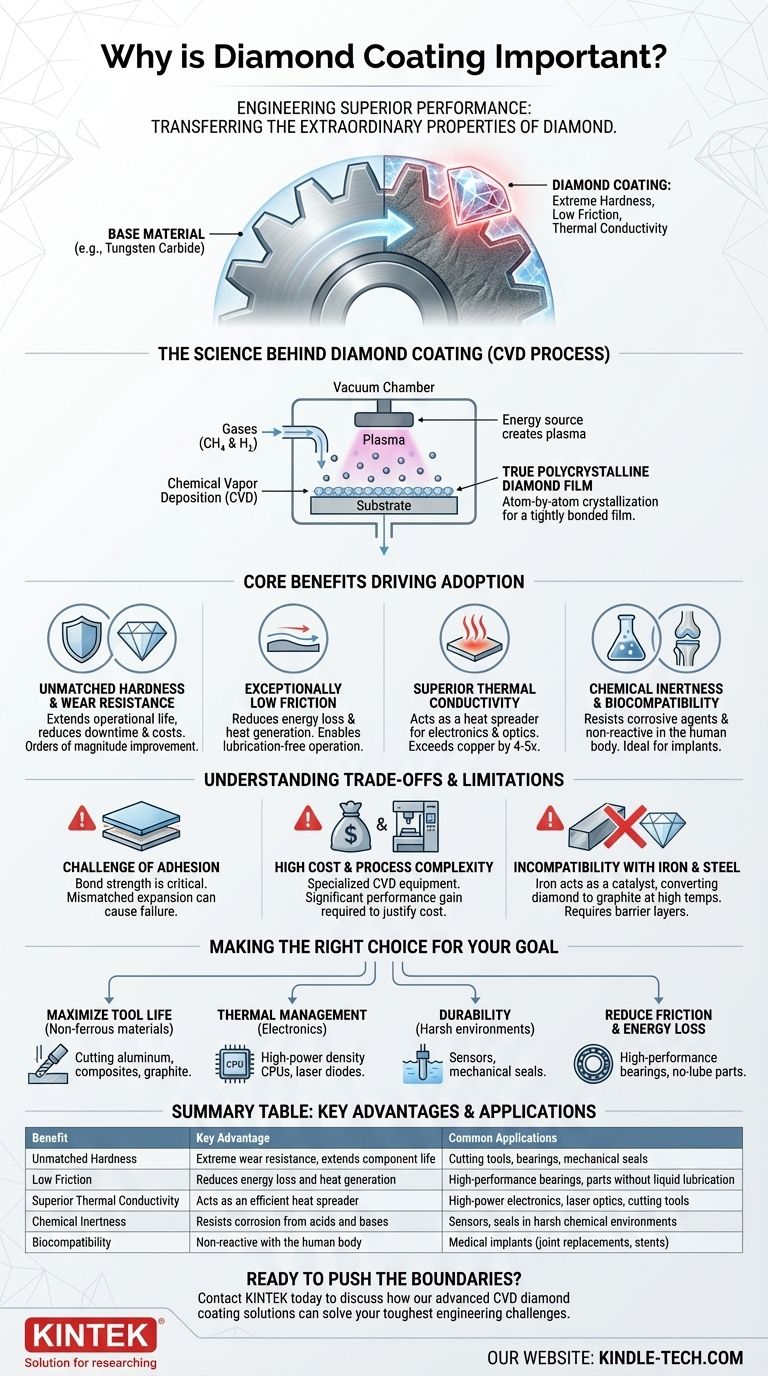

In short, diamond coating is important because it transfers the extraordinary properties of diamond—like extreme hardness and low friction—onto the surface of more common materials. This process creates high-performance components that last longer, run more efficiently, and can operate in environments where the base material would quickly fail. It is a strategic enhancement, not just a simple layer.

Diamond coating is a method for engineering superior performance. It allows us to give a material's surface the elite capabilities of diamond without having to make the entire object out of expensive, difficult-to-work-with solid diamond.

The Science Behind Diamond Coating

A Layer of Extreme Performance

Diamond coating, often referred to as diamond-like carbon (DLC) or true polycrystalline diamond film, is an ultra-thin layer of lab-grown diamond deposited onto a substrate material.

This isn't a paint or plating; it's a film that fundamentally bonds with the surface, giving it a new set of operational characteristics. The goal is to combine the desirable bulk properties of a substrate (like the toughness of tungsten carbide) with the superior surface properties of diamond.

The CVD Deposition Process

The most common method for applying a true diamond coating is Chemical Vapor Deposition (CVD).

In this process, a substrate is placed in a vacuum chamber. A mixture of gases, typically including a carbon source like methane and hydrogen, is introduced. When energized (using methods like hot filaments or microwaves), the gases react, causing carbon atoms to "rain" down and crystallize on the substrate's surface, forming a genuine, tightly bonded diamond film.

The Core Benefits Driving Adoption

Unmatched Hardness and Wear Resistance

Diamond is the hardest known material. Applying it as a coating dramatically increases a component's resistance to abrasive and adhesive wear.

This extends the operational life of cutting tools, bearings, mechanical seals, and wear-resistant parts by orders of magnitude, reducing downtime and replacement costs.

Exceptionally Low Friction

Diamond surfaces have a very low coefficient of friction, especially against other materials. This is often compared to wet ice on wet ice.

This property is critical for moving parts, as it reduces energy loss, minimizes heat generation, and can even allow systems to run without traditional liquid lubricants.

Superior Thermal Conductivity

While being an electrical insulator, diamond is the best thermal conductor known to man, exceeding copper by a factor of four or five.

A diamond coating can act as a heat spreader, rapidly pulling damaging heat away from a critical area. This is essential for high-power electronics, laser optics, and high-speed cutting tools where heat is the primary cause of failure.

Chemical Inertness and Biocompatibility

Diamond is chemically inert, meaning it does not react with most acids, bases, or other corrosive agents. This makes it an ideal coating for components used in harsh chemical processing environments.

Furthermore, its carbon structure is biocompatible, meaning the human body does not reject it. This has opened the door for its use in long-lasting medical implants, such as joint replacements and cardiovascular stents.

Understanding the Trade-offs and Limitations

The Challenge of Adhesion

The single greatest challenge with diamond coating is ensuring it sticks to the substrate. The bond between the diamond film and the base material is a potential point of failure.

Poor surface preparation or a mismatch in thermal expansion between the coating and the substrate can cause the diamond layer to delaminate, chip, or flake off under stress.

High Cost and Process Complexity

CVD is a sophisticated and energy-intensive process that requires specialized, expensive equipment. This makes diamond-coated parts significantly more expensive than their uncoated counterparts.

The cost must be justified by a significant performance gain, such as drastically increased tool life or enabling a new technological capability.

Incompatibility with Iron and Steel

Diamond coating does not work well on ferrous materials like steel. At the high temperatures of the CVD process, the iron acts as a catalyst, converting the depositing diamond into worthless graphite.

To coat steel parts, an intermediate barrier layer (like titanium nitride) must first be applied, which adds complexity and cost to the process.

Making the Right Choice for Your Goal

Deciding to use a diamond coating is an engineering trade-off between extreme performance and higher cost. The choice depends entirely on the primary problem you need to solve.

- If your primary focus is maximizing tool life for non-ferrous materials: Diamond coating provides unparalleled wear resistance for cutting aluminum, composites, and graphite.

- If your primary focus is thermal management in electronics: A diamond coating acts as a highly effective heat spreader for high-power density CPUs or laser diodes.

- If your primary focus is durability in a harsh environment: The chemical inertness of diamond makes it ideal for sensors or mechanical seals exposed to corrosive agents.

- If your primary focus is reducing friction and energy loss: Diamond coating is a top-tier solution for high-performance bearings or parts where liquid lubrication is impossible.

Ultimately, diamond coating is a powerful tool for pushing the boundaries of material performance where conventional solutions fall short.

Summary Table:

| Benefit | Key Advantage | Common Applications |

|---|---|---|

| Unmatched Hardness | Extreme wear resistance, extends component life | Cutting tools, bearings, mechanical seals |

| Low Friction | Reduces energy loss and heat generation | High-performance bearings, parts without liquid lubrication |

| Superior Thermal Conductivity | Acts as an efficient heat spreader | High-power electronics, laser optics, cutting tools |

| Chemical Inertness | Resists corrosion from acids and bases | Sensors, seals in harsh chemical environments |

| Biocompatibility | Non-reactive with the human body | Medical implants (joint replacements, stents) |

Ready to push the boundaries of your material performance?

If your components face extreme wear, heat, or corrosive environments, a diamond coating from KINTEK can be the strategic enhancement that delivers superior performance and longevity. Our expertise in Chemical Vapor Deposition (CVD) processes ensures a high-quality, durable bond for your critical applications.

Contact KINTEK today to discuss how our advanced diamond coating solutions can solve your toughest engineering challenges and provide a significant return on investment. Let's engineer superior performance together.

Visual Guide

Related Products

- Laboratory CVD Boron Doped Diamond Materials

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- CVD Diamond Domes for Industrial and Scientific Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- What is the role of an HFCVD reactor in synthesizing boron-doped diamond? Expert Guide to Diamond Gas Activation

- What physical conditions does an HPHT press provide for BDD synthesis? Achieve Extreme 5 GPa & 1800 K Conditions

- What is the purpose of performing anodic polarization on BDD electrodes? Ensure Accurate & Reproducible Research Results

- What is the carbon footprint of diamond mining? Uncovering the True Environmental and Ethical Cost

- What is the role of the HF-CVD system in preparing BDD electrodes? Scalable Solutions for Boron-Doped Diamond Production