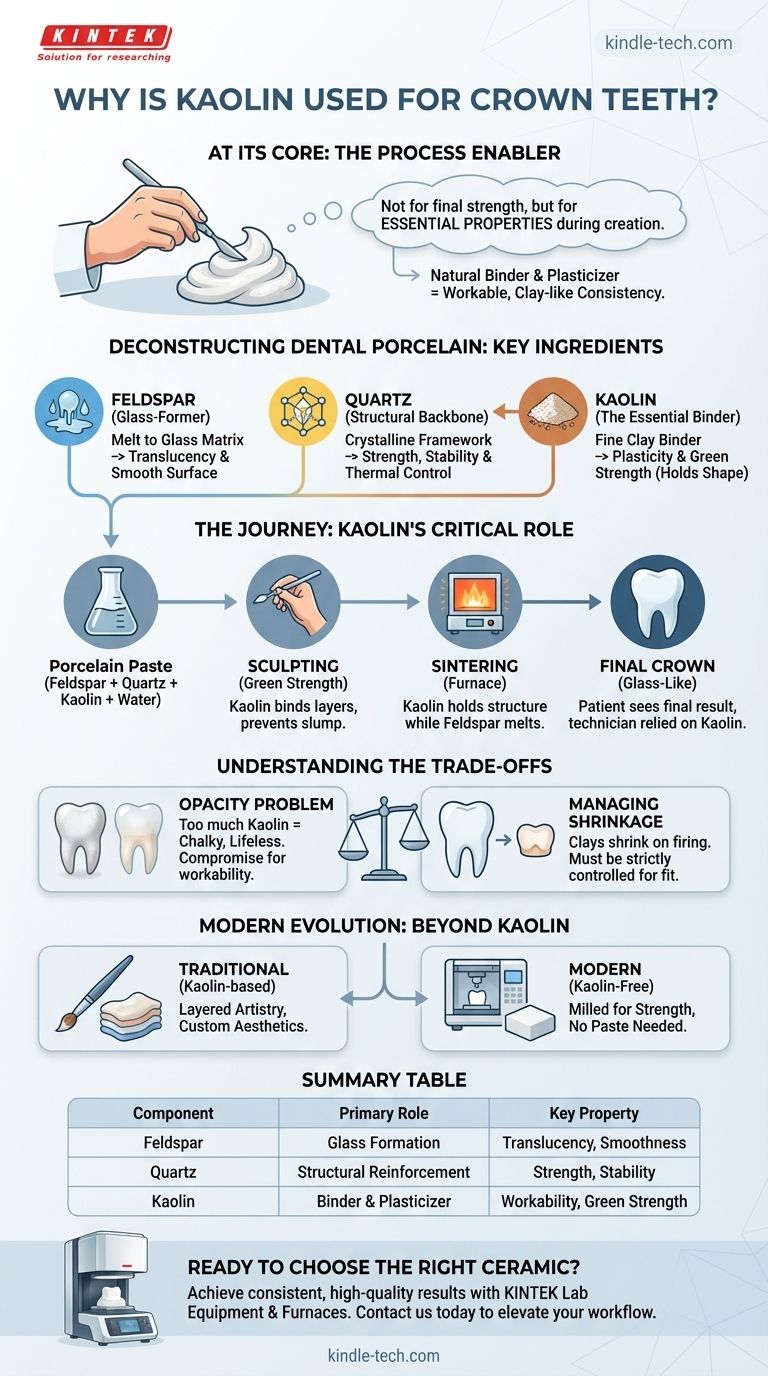

At its core, kaolin is used in the fabrication of traditional porcelain dental crowns not for its final strength, but for its essential properties during the creation process. It functions as a natural binder and plasticizer, giving the raw porcelain paste the workable, clay-like consistency that allows a dental technician to expertly sculpt the tooth's shape before it is fired and hardened in a furnace.

While patients see the final, glass-like crown, the technician relies on kaolin to make that result possible. It provides critical "green strength" to the unfired material, preventing it from slumping or cracking during shaping and handling.

Deconstructing Dental Porcelain: The Key Ingredients

To understand kaolin’s role, you must first understand that traditional dental porcelain is not a single substance but a carefully balanced composite material, primarily made of three natural minerals.

Feldspar: The Glass-Former

Feldspar is the primary component of dental porcelain. When heated to high temperatures in a dental furnace, it melts to form a glass matrix. This glassy phase is what gives a finished crown its crucial translucency and smooth, stain-resistant surface.

Quartz (Silica): The Structural Backbone

Quartz is a crystalline filler that does not melt at the same temperatures as feldspar. It acts as a stable, high-strength framework within the molten feldspar. This crystalline structure reinforces the final crown, providing strength and stability and controlling thermal expansion.

Kaolin: The Essential Binder

Kaolin is a fine, white clay. It is the key ingredient that makes the mixture of feldspar and quartz powders workable. When mixed with water, kaolin makes the paste plastic, allowing it to be molded and shaped without crumbling. It acts as a binder, holding the other particles together before they are fused by heat.

The Journey from Paste to Crown: Kaolin's Critical Role

Kaolin's importance is most evident during the manual fabrication stages of a porcelain-fused-to-metal (PFM) or traditional all-ceramic crown.

Building the Unfired Crown

A dental technician meticulously applies the porcelain paste in layers to build up the anatomy of the tooth. Kaolin's binding properties are what allow these layers to adhere to one another and maintain their form. This is often referred to as providing "green strength"—the strength of the object before it's fired.

Surviving the Furnace

As the crown is heated in a process called sintering, the kaolin continues to hold the structure's shape while the feldspar begins to melt and flow around the quartz particles. Without kaolin, the carefully sculpted powder would simply collapse into a pile.

Understanding the Trade-offs: The Limits of Kaolin

While essential for fabrication, the amount of kaolin in dental porcelain must be strictly limited. Its properties present a clear trade-off between workability and final aesthetics.

The Opacity Problem

Kaolin is a clay, and like most clays, it is opaque. The primary aesthetic goal of a dental crown is to mimic the natural translucency of a tooth. Using too much kaolin would result in a chalky, opaque, and lifeless-looking restoration, defeating the purpose of using porcelain. Its use is a compromise, adding just enough for workability while minimizing its impact on light transmission.

Managing Shrinkage

Clays shrink significantly when they are fired and the water is driven off. The percentage of kaolin must be carefully controlled to predict and manage this shrinkage. Excessive shrinkage would result in a crown that does not fit the underlying tooth preparation, rendering it useless.

The Evolution to Modern Ceramics

It is critical to note that many modern, high-strength dental ceramics, such as zirconia and lithium disilicate (e.max), do not use kaolin. These materials are often milled from a solid block using CAD/CAM technology, completely bypassing the need for a manually buildable, plastic paste. Their chemistry and manufacturing processes are entirely different.

Making the Right Choice for Your Goal

Understanding the role of each component allows for a deeper appreciation of the different types of dental restorations available.

- If your primary focus is traditional artistry and layered aesthetics: Kaolin is the unsung hero in feldspathic porcelain that enables a technician to create highly customized, multi-chromatic restorations.

- If your primary focus is maximum strength: You will likely be looking at modern, kaolin-free materials like monolithic zirconia, which prioritize durability over the layered translucency of traditional porcelain.

- If your primary focus is a balance of aesthetics and strength: Materials like lithium disilicate or layered zirconia offer a compromise, often using milling for the core structure and potentially layering with traditional porcelains for a superior aesthetic result.

Ultimately, understanding the science of the materials used in dentistry empowers you to better comprehend why a specific solution is recommended for a specific clinical need.

Summary Table:

| Component | Primary Role | Key Property |

|---|---|---|

| Feldspar | Glass Formation | Translucency, smooth surface |

| Quartz | Structural Reinforcement | Strength, stability |

| Kaolin | Binder & Plasticizer | Workability, green strength |

Ready to choose the right dental ceramic for your lab's needs? Whether you're working with traditional feldspathic porcelain or modern high-strength materials like zirconia, having the right equipment is crucial. KINTEK specializes in lab equipment and consumables, including dental furnaces essential for sintering these materials to perfection. Let our expertise help you achieve consistent, high-quality results. Contact us today to discuss how we can support your laboratory's workflow and elevate your dental restorations.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is a ceramic dental furnace? A Precision Tool for Durable, Aesthetic Restorations

- What is the sintering time for zirconia crowns? Master the Trade-Off Between Speed and Strength

- What are the disadvantages of all-ceramic restorations? Key Limitations for Long-Term Success

- How strong is dental ceramic? Discover Materials Stronger Than Natural Tooth Enamel

- What is the temperature of sintering zirconia? Mastering the Protocol for Perfect Dental Restorations

- What is a dental press used for? Creating High-Strength, Aesthetic Dental Restorations

- What is the use of burnout oven? The Critical Step for Flawless Casting Results

- What are the components of dental porcelain? A Guide to Engineered Strength and Beauty