Yes, a CVD diamond will pass a standard diamond tester. These testers are designed to identify the unique physical properties of a diamond, specifically its high thermal or electrical conductivity. Because a lab-grown CVD diamond is chemically and structurally a real diamond, it possesses these same properties and will be correctly identified as such by a handheld tester.

The core issue is not one of authenticity, but of origin. Standard diamond testers can confirm a stone is a diamond, but they cannot distinguish between a diamond grown in a lab and one mined from the earth. That distinction requires specialized laboratory equipment.

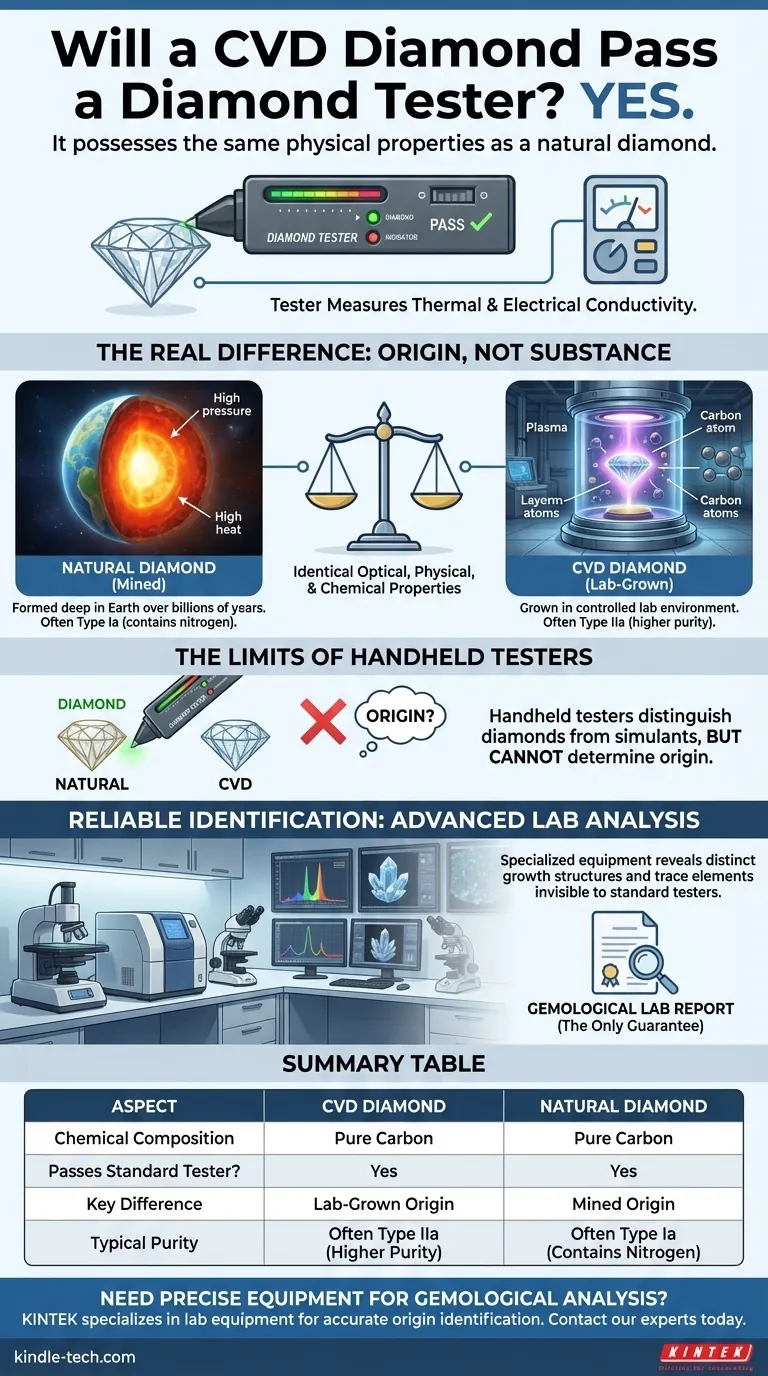

Why Standard Testers Identify CVD as Diamond

How Diamond Testers Work

Most common handheld diamond testers work by measuring how quickly heat or electricity moves through a gemstone. Diamonds are exceptional thermal and electrical conductors, a property that distinguishes them from common simulants like cubic zirconia or glass. A tester simply touches the stone with a small probe and measures this conductivity.

The Identical Nature of CVD Diamonds

A Chemical Vapor Deposition (CVD) diamond is not a "fake" diamond; it is a synthetic or lab-created diamond. It is made of the same material as a natural diamond: pure, crystallized carbon. As a result, it shares the exact same optical, physical, and chemical properties, including the high conductivity that testers are designed to detect.

The Real Difference: Origin, Not Substance

A Matter of Creation

The only true difference between a natural and a CVD diamond is its origin story. Natural diamonds form deep within the Earth's mantle under immense pressure and heat over billions of years. CVD diamonds are grown in a highly controlled laboratory chamber by layering carbon atoms onto a diamond seed. They are simply two different methods of producing the same final material.

A Higher Level of Purity

Interestingly, the controlled environment of a lab often results in CVD diamonds having fewer chemical impurities than their natural counterparts. Most natural diamonds contain trace amounts of nitrogen, classifying them as Type Ia. Many CVD diamonds are free of these impurities, classifying them as the rarer and purer Type IIa. This is a key difference, but one that is invisible to a standard diamond tester.

Methods for Reliable Identification

The Limits of Handheld Testers

It is critical to understand the purpose of a standard tester. Its job is to separate diamonds (both natural and lab-grown) from non-diamond simulants. It cannot solve the question of origin. Any claim that a simple handheld device can reliably distinguish between the two should be met with extreme skepticism.

The Role of Gemological Labs

True identification requires analysis in a professional gemological laboratory. Experts use advanced spectroscopic instruments to examine a diamond's growth structure and detect the presence of trace elements. The layered growth pattern of a CVD diamond is distinct from the crystalline structure of a natural diamond, and this can be observed under high magnification and specialized lighting.

The Importance of Certification

For any consumer, the safest and most reliable method of verification is the diamond's certificate. Reputable labs like the Gemological Institute of America (GIA) will always test for origin. A certificate for a lab-grown diamond will clearly state the origin as "Laboratory-Grown" and may specify the growth method (CVD or HPHT) in the comments section.

How to Be Certain of Your Diamond's Origin

- If your primary focus is buying with confidence: Always demand a full grading report from a reputable gemological lab and check the "Origin" section. This is your only guarantee.

- If your primary focus is basic verification: Use a standard tester to confirm a stone is a diamond rather than a simulant like cubic zirconia, but do not rely on it to determine if that diamond is natural.

- If your primary focus is identifying an unknown stone: The only definitive path is to submit the diamond to a professional gemological laboratory for a full analysis and report.

Ultimately, understanding the capabilities and limitations of your tools is key to making an informed decision.

Summary Table:

| Aspect | CVD Diamond | Natural Diamond |

|---|---|---|

| Chemical Composition | Pure Carbon | Pure Carbon |

| Passes Standard Tester? | Yes | Yes |

| Key Difference | Lab-Grown Origin | Mined Origin |

| Typical Purity | Often Type IIa (Higher Purity) | Often Type Ia (Contains Nitrogen) |

Need precise, reliable equipment for advanced gemological analysis? KINTEK specializes in the lab equipment and consumables that professional gemological laboratories rely on to accurately identify diamond origin. Ensure your lab's credibility and precision—contact our experts today to find the right tools for your needs.

Visual Guide

Related Products

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- CVD Diamond Domes for Industrial and Scientific Applications

- CVD Diamond Wire Drawing Die Blanks for Precision Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- Which is advantage of chemical vapor deposition? Achieve Superior, Uniform Coatings on Complex Parts

- What are the pros and cons of physical vapor deposition? A Guide to PVD vs. CVD Coating

- Which method is used mostly to synthesize single wall carbon nanotubes? Chemical Vapor Deposition (CVD) is the Industry Standard

- How does Chemical Vapor Deposition (CVD) equipment facilitate high thermal conductivity channels? Precision Control Guide

- What are the system variables that affect the deposition rate for thermal deposition? Control Your Thin Film Growth

- What are the characteristics of thin films? Harnessing Unique Properties for Advanced Applications

- What is the role of argon in CVD? Mastering Precise Film Deposition Control

- What is High Temperature Chemical Vapour Deposition (HTCVD) used for? Advanced Silicon Carbide Crystal Growth