While technically possible in very limited scenarios, using stainless steel as a crucible is overwhelmingly a poor and often dangerous choice for melting most metals. Its melting point is too low, it contaminates the molten metal, and it is prone to catastrophic failure at the high temperatures required for casting. For any serious or safe metalwork, a purpose-built crucible is the only correct tool.

The core issue is a mismatch of material properties. Stainless steel is designed for corrosion resistance and strength at ordinary temperatures, not for containing molten metal. A proper crucible is made from refractory materials specifically engineered to withstand extreme heat, thermal shock, and chemical reactions without failing or contaminating your work.

The Allure and The Reality of Stainless Steel

Many people consider stainless steel because it seems like a robust, heat-resistant material that is readily available. This perception, while true for applications like cookware or exhaust systems, does not translate to the extreme environment of a furnace.

Its Perceived Strengths

Stainless steel is strong, resists oxidation at moderate temperatures, and can be found easily in the form of pots, pans, or pipe sections. This leads to the assumption that it could serve as a durable, reusable melting pot.

The Critical Distinction: Heat-Resistant vs. Refractory

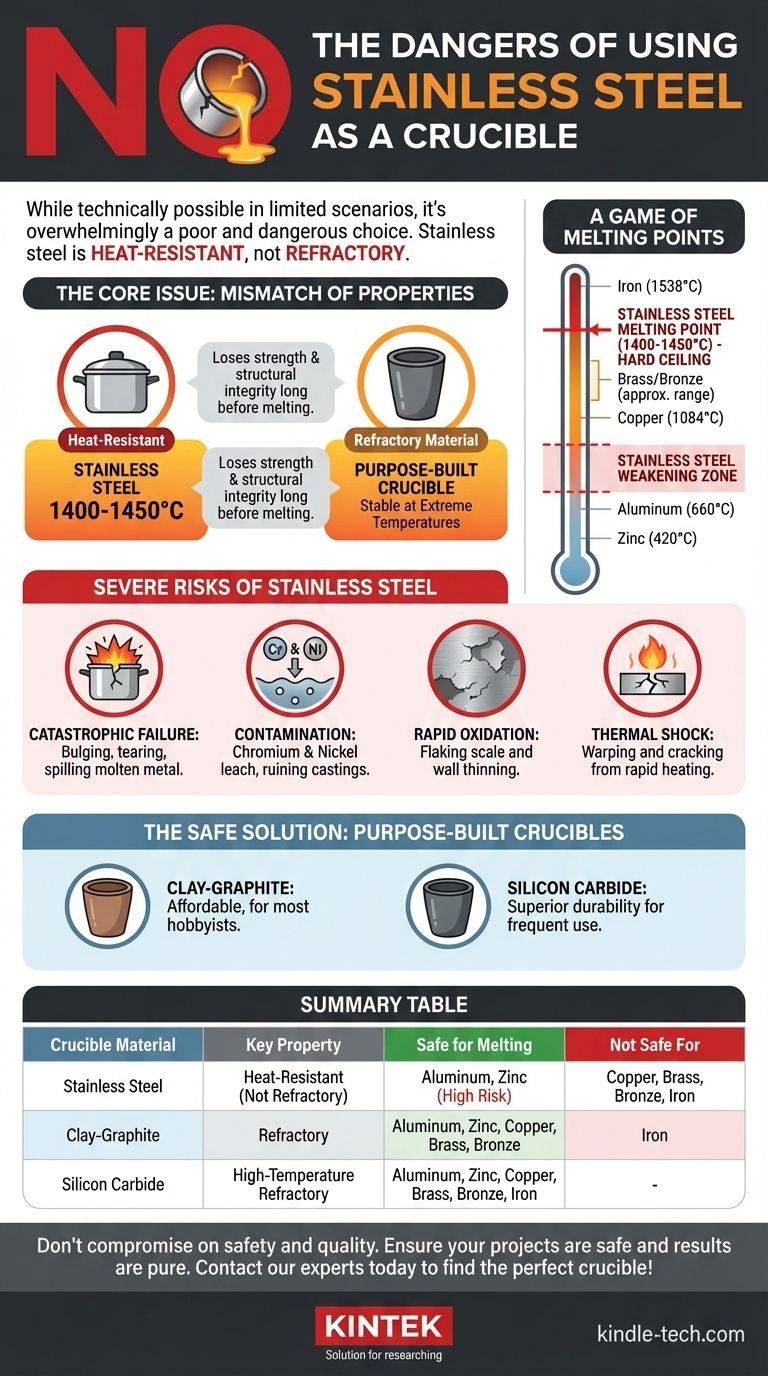

"Heat-resistant" means a material can operate at elevated temperatures without losing its shape, like an oven rack. "Refractory" means a material is chemically and physically stable at the extreme temperatures needed for melting metals. Stainless steel is heat-resistant; it is not a refractory material.

The Core Problem: A Game of Melting Points

The fundamental reason stainless steel fails as a crucible is that its own melting point is often too close to—or even lower than—the metal you wish to melt.

Stainless Steel's Melting Temperature

Most common stainless steel alloys (like 304 or 316) melt around 1400-1450°C (2550-2640°F). This is a hard ceiling, but the material begins to lose its structural integrity at far lower temperatures.

Comparing Common Metals

- Viable (but risky): Aluminum melts at 660°C (1220°F) and Zinc at 420°C (787°F). Stainless steel can contain these, but other problems like contamination still exist.

- Dangerous: Copper melts at 1084°C (1983°F) and Brass/Bronze alloys melt in a similar range. At these temperatures, a stainless steel container will be severely weakened, glowing bright orange-yellow, and on the verge of sagging and splitting open.

- Impossible: Iron melts at 1538°C (2800°F). A stainless steel crucible will melt before the iron does.

The Danger Zone of Weakening

A material does not need to reach its melting point to fail. Long before it turns to liquid, stainless steel will lose the majority of its strength, becoming soft and plastic. The sheer weight of molten metal inside it can easily cause the container to bulge, tear, and spill its contents.

Understanding the Severe Risks

Using a stainless steel container is not a simple trade-off for convenience; it introduces significant hazards and guarantees poor results for most metals.

Catastrophic Failure and Spills

This is the primary safety risk. The container can fail without warning, releasing hundreds or thousands of degrees of molten metal onto your work area, equipment, and potentially yourself. This can cause severe burns and explosive fires.

Contamination and Ruined Castings

As stainless steel heats up, elements like chromium and nickel will leach from the crucible into your molten metal. This will contaminate your melt, altering the properties of your final cast. An aluminum casting might become brittle, and a bronze casting may have its color and strength ruined.

Rapid Oxidation and Scaling

At melting temperatures, the protective chromium oxide layer on stainless steel breaks down. The steel will rapidly oxidize, creating flakes of "scale" that fall into your melt as impurities. This process also thins the wall of the container, accelerating its path to failure.

Susceptibility to Thermal Shock

Crucibles are designed to handle the thermal shock of rapid heating and cooling. Stainless steel is not. Heating it too quickly can cause it to warp and crack. A small, invisible crack can become a complete rupture once filled with heavy, molten metal.

Making the Right Choice for Your Goal

Always prioritize safety and the quality of your final product. The choice of container is not a corner you can afford to cut.

- If you are melting low-temperature metals (like aluminum or zinc) for a one-off, non-critical project: A heavy-walled stainless steel pot might survive a few uses, but it is still highly risky and will contaminate your metal.

- If you are melting copper, brass, bronze, or anything with a higher melting point: Do not use stainless steel under any circumstances. It will fail.

- If your primary focus is safety, quality, and repeatability: You must use a purpose-built crucible. A clay-graphite crucible is an excellent and affordable starting point for most hobbyists, while silicon carbide crucibles offer superior durability for more frequent use.

Investing in the correct tool is the first and most critical step toward safe and successful metalwork.

Summary Table:

| Crucible Material | Key Property | Safe for Melting | Not Safe For |

|---|---|---|---|

| Stainless Steel | Heat-Resistant (Not Refractory) | Aluminum, Zinc (with high risk) | Copper, Brass, Bronze, Iron |

| Clay-Graphite | Refractory | Aluminum, Zinc, Copper, Brass, Bronze | Iron |

| Silicon Carbide | High-Temperature Refractory | Aluminum, Zinc, Copper, Brass, Bronze, Iron | - |

Don't compromise on safety and quality. The right crucible is essential for successful and safe metalwork. KINTEK specializes in high-performance lab equipment and consumables, including durable crucibles made from refractory materials like clay-graphite and silicon carbide, designed to withstand extreme heat without failure or contamination. Ensure your projects are safe and your results are pure. Contact our experts today to find the perfect crucible for your specific needs!

Visual Guide

Related Products

- Custom Machined and Molded PTFE Teflon Parts Manufacturer with PTFE Crucible and Lid

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Electron Beam Evaporation Coating Tungsten Crucible and Molybdenum Crucible for High Temperature Applications

- Alumina Al2O3 Ceramic Crucible Semicircle Boat with Lid for Engineering Advanced Fine Ceramics

People Also Ask

- What are crucibles used for in lab? Ensuring Accurate, High-Temperature Sample Analysis

- What is a crucible material for a furnace? A Guide to Choosing the Right High-Temperature Container

- What is the best type of crucible? The Answer Depends on Your Application's Needs

- Is a crucible a lab equipment? A Guide to High-Temperature Containers for Labs and Foundries

- How do you clean a melting crucible? Protect Your Crucible and Ensure Metal Purity