Lab Materials

Calcium Fluoride (CaF2) Sputtering Target / Powder / Wire / Block / Granule

Item Number : LM-CaF2

Price varies based on specs and customizations

- Chemical Formula

- CaF2

- Purity

- 4N

- Shape

- discs / wire / block / powder / plates / column targets / step target / custom-made

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

At our laboratory, we offer Calcium Fluoride (CaF2) materials at competitive prices. Our specialty is producing and customizing Calcium Fluoride (CaF2) materials with varying purities, shapes, and sizes to meet your specific needs.

We provide a wide range of specifications and sizes for different types of materials, including sputtering targets (circular, square, tubular, irregular), coating materials, cylinders, cones, particles, foils, powders, 3D printing powders, nanometer powders, wire rods, ingots, and blocks, among others.

Details

About Calcium Fluoride (CaF2)

Calcium fluoride is an inorganic compound composed of calcium and fluorine with the formula CaF2. It is a white insoluble solid and occurs as the mineral fluorite, which can be deeply colored due to impurities.

Naturally occurring CaF2 is a primary source of hydrogen fluoride, a commodity chemical used to produce various materials. Calcium fluoride in the fluorite state is of significant commercial importance as a fluoride source. Hydrogen fluoride is produced by the action of concentrated sulfuric acid on the mineral.

Calcium fluoride is utilized to manufacture optical components such as windows and lenses, which are used in thermal imaging systems, spectroscopy, telescopes, and excimer lasers (used for photolithography in the form of a fused lens). It is transparent over a broad range of frequencies from ultraviolet (UV) to infrared (IR) and has a low refractive index that reduces the need for anti-reflection coatings. Its insolubility in water is also convenient and enables much smaller wavelengths to pass through.

Doped calcium fluoride, like natural fluorite, exhibits thermoluminescence and is used in thermoluminescent dosimeters. Calcium fluoride forms when fluorine combines with calcium.

Calcium Fluoride is a water-insoluble Calcium source used in oxygen-sensitive applications such as metal production. Fluoride compounds have diverse applications in current technologies and science, from oil refining and etching to synthetic organic chemistry and the manufacture of pharmaceuticals.

Magnesium Fluoride was used by researchers at the Max Planck Institute for Quantum Optics in 2013 to create a novel mid-infrared optical frequency comb composed of crystalline microresonators, which may lead to future advances in molecular spectroscopy. Fluorides are also commonly used to alloy metals and for optical deposition.

Calcium Fluoride is generally available in most volumes and is offered in ultra-high purity and high purity compositions that improve optical quality and usefulness as scientific standards. Nanoscale elemental powders and suspensions, as alternative high surface area forms, may also be considered.

Ingredient Quality Control

- Raw material composition analysis

- Through the use of equipment such as ICP and GDMS, the content of metal impurities is detected and analyzed to ensure that it meets the purity standard;

Non-metallic impurities are detected by equipment such as carbon and sulfur analyzers, nitrogen and oxygen analyzers. - Metallographic flaw detection analysis

- The target material is inspected using flaw detection equipment to ensure that there are no defects or shrinkage holes inside the product;

Through metallographic testing, the internal grain structure of the target material is analyzed to ensure that the grains are fine and dense. - Appearance and dimension inspection

- Product dimensions are measured using micrometers and precision calipers to ensure compliance with drawings;

The surface finish and cleanliness of the product are measured using a surface cleanliness meter.

Conventional Sputtering Target Sizes

- Preparation process

- hot isostatic pressing, vacuum melting, etc.

- Sputtering target shape

- plane sputtering target, multi-arc sputtering target, step sputtering target, special-shaped sputtering target

- Round sputtering target size

- Diameter: 25.4mm / 50mm / 50.8mm / 60mm / 76.2mm / 80mm / 100mm / 101.6mm / 152.4mm

Thickness: 3mm / 4mm / 5mm / 6mm / 6.35mm

Size can be customized. - Square sputtering target size

- 50×50×3mm / 100×100×4mm / 300×300×5mm, size can be customized

Available Metal Forms

Metal Forms Details

We manufacture almost all the metals listed on the periodic table in a wide range of forms and purities, as well as standard sizes and dimensions. We can also produce custom-made products to meet specific customer requirements, such as size, shape, surface area, composition, and more. The following list provides a sample of the forms we offer, but it is not exhaustive. If you need laboratory consumables, please contact us directly to request a quote.

- Flat/Planar Forms: Board, Film, Foil, Microfoil, Microleaf, Paper, Plate, Ribbon, Sheet, Strip, Tape, Wafer

- Preformed Shapes: Anodes, Balls, Bands, Bars, Boats, Bolts, Briquettes, Cathodes, Circles, Coils, Crucibles, Crystals, Cubes, Cups, Cylinders, Discs, Electrodes, Fibers, Filaments, Flanges, Grids, Lenses, Mandrels, Nuts, Parts, Prisms, Pucks, Rings, Rods, Shapes, Shields, Sleeves, Springs, Squares, Sputtering Targets, Sticks, Tubes, Washers, Windows, Wires

- Microsizes: Beads, Bits, Capsules, Chips, Coins, Dust, Flakes, Grains, Granules, Micropowder, Needles, Particles, Pebbles, Pellets, Pins, Pills, Powder, Shavings, Shot, Slugs, Spheres, Tablets

- Macrosizes: Billets, Chunks, Cuttings, Fragments, Ingots, Lumps, Nuggets, Pieces, Punchings, Rocks, Scraps, Segments, Turnings

- Porous and Semi-Porous: Fabric, Foam, Gauze, Honeycomb, Mesh, Sponge, Wool

- Nanoscale: Nanoparticles, Nanopowders, Nanofoils, Nanotubes, Nanorods, Nanoprisms

- Others: Concentrate, Ink, Paste, Precipitate, Residue, Samples, Specimens

KinTek specializes in the manufacturing of high-purity and ultra-high-purity materials with a purity range of 99.999% (5N), 99.9999% (6N), 99.99995% (6N5), and in some cases, up to 99.99999% (7N). Our materials are available in specific grades, including UP/UHP, semiconductor, electronic, deposition, fiber optic, and MBE grades. Our high-purity metals, oxides, and compounds are specifically crafted to meet the rigorous demands of high-technology applications and are ideal for use as dopants and precursor materials for thin film deposition, crystal growth of semiconductors, and synthesis of nanomaterials. These materials find use in advanced microelectronics, solar cells, fuel cells, optical materials, and other cutting-edge applications.

Packaging

We use vacuum packaging for our high-purity materials, and each material has specific packaging tailored to its unique characteristics. For instance, our Hf sputter target is externally tagged and labeled to facilitate efficient identification and quality control. We take great care to prevent any damage that could occur during storage or transportation.

4.9

out of

5

The Calcium Fluoride from KINTEK SOLUTION is a great choice for our research. It's pure and consistent, leading to reliable results.

4.8

out of

5

Excellent quality and fast delivery. The Calcium Fluoride target met our expectations and helped us achieve desired results.

4.7

out of

5

I highly recommend KINTEK SOLUTION's Calcium Fluoride. It's cost-effective and enabled us to optimize our production process.

4.9

out of

5

We were impressed with the purity and consistency of the Calcium Fluoride. It helped us obtain accurate and reproducible data.

4.8

out of

5

The Calcium Fluoride from KINTEK SOLUTION is a top-notch product. It's reliable and has helped us enhance our research capabilities.

4.7

out of

5

KINTEK SOLUTION's Calcium Fluoride is exceptional. Its high quality has enabled us to push the boundaries of our research.

4.9

out of

5

We are highly satisfied with the Calcium Fluoride from KINTEK SOLUTION. It's a game-changer for our research and has accelerated our progress.

4.8

out of

5

KINTEK SOLUTION's Calcium Fluoride has been a valuable addition to our lab. It's a reliable and cost-effective choice.

4.7

out of

5

We highly recommend the Calcium Fluoride from KINTEK SOLUTION. Its purity and consistency have made a significant impact on our research.

4.9

out of

5

KINTEK SOLUTION's Calcium Fluoride is a lifesaver. It has helped us achieve remarkable results in our research and has exceeded our expectations.

4.8

out of

5

We are thoroughly impressed with the quality of Calcium Fluoride from KINTEK SOLUTION. It's a valuable asset to our lab and has enabled us to make significant advancements in our research.

4.7

out of

5

KINTEK SOLUTION's Calcium Fluoride is a remarkable product. It's a testament to their commitment to quality and innovation.

4.9

out of

5

We highly recommend the Calcium Fluoride from KINTEK SOLUTION. It's a game-changer for our research and has helped us achieve groundbreaking results.

4.8

out of

5

KINTEK SOLUTION's Calcium Fluoride is a lifesaver. It's a valuable addition to our lab and has enabled us to make significant progress in our research.

4.7

out of

5

We are thoroughly impressed with the quality of Calcium Fluoride from KINTEK SOLUTION. It's a valuable asset to our lab and has enabled us to make significant advancements in our research.

4.9

out of

5

KINTEK SOLUTION's Calcium Fluoride is a remarkable product. It's a testament to their commitment to quality and innovation.

4.8

out of

5

We highly recommend the Calcium Fluoride from KINTEK SOLUTION. It's a game-changer for our research and has helped us achieve groundbreaking results.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Sodium Fluoride (NaF) Sputtering Target / Powder / Wire / Block / Granule

Looking for Sodium Fluoride (NaF) materials? We offer tailored solutions of different purities, shapes, and sizes at affordable prices. Find sputtering targets, coating materials, powders, and more. Contact us today.

Magnesium Fluoride (MgF2) Sputtering Target / Powder / Wire / Block / Granule

Looking for high-quality Magnesium Fluoride (MgF2) materials for your laboratory needs? Look no further! Our expertly tailored materials come in a range of purities, shapes, and sizes to meet your specific requirements. Shop now for sputtering targets, powders, ingots, and more.

Potassium Fluoride (KF) Sputtering Target / Powder / Wire / Block / Granule

Get top-quality Potassium Fluoride (KF) materials for your lab needs at great prices. Our tailored purities, shapes, and sizes suit your unique requirements. Find sputtering targets, coating materials, and more.

Barium Fluoride (BaF2) Sputtering Target / Powder / Wire / Block / Granule

Shop Barium Fluoride (BaF2) materials at affordable prices. We tailor to your needs with a range of sputtering targets, coating materials, powders, and more. Order now.

Strontium Fluoride (SrF2) Sputtering Target / Powder / Wire / Block / Granule

Looking for Strontium Fluoride (SrF2) materials for your laboratory? Look no further! We offer a range of sizes and purities, including sputtering targets, coatings, and more. Order now at reasonable prices.

MgF2 magnesium fluoride crystal substrate / window

Magnesium fluoride (MgF2) is a tetragonal crystal that exhibits anisotropy, making it imperative to treat it as a single crystal when engaging in precision imaging and signal transmission.

Iridium dioxide IrO2 for electrolysis of water

Iridium dioxide, whose crystal lattice is rutile structure. Iridium dioxide and other rare metal oxides can be used in anode electrodes for industrial electrolysis and microelectrodes for electrophysiological research.

Lithium Tantalate (LiTaO3) Sputtering Target / Powder / Wire / Block / Granule

Find affordable Lithium Tantalate materials for laboratory use at our company. We specialize in producing tailored shapes and sizes to suit your unique needs, including sputtering targets, coating materials, and more.

CaF2 substrate / window / lens

A CaF2 window is an optical window made of crystalline calcium fluoride. These windows are versatile, environmentally stable and resistant to laser damage, and they exhibit a high, stable transmission from 200 nm to about 7 μm.

High Purity Bismuth (Bi) Sputtering Target / Powder / Wire / Block / Granule

Looking for Bismuth (Bi) materials? We offer affordable laboratory-grade materials in various shapes, sizes, and purities to meet your unique requirements. Check out our sputtering targets, coating materials, and more!

barium fluoride (BaF2) substrate / window

BaF2 is the fastest scintillator, sought-after for its exceptional properties. Its windows and plates are valuable for VUV and infrared spectroscopy.

Thermally evaporated tungsten wire

It has a high melting point, thermal and electrical conductivity, and corrosion resistance. It is a valuable material for high temperature, vacuum and other industries.

High Purity Indium (In) Sputtering Target / Powder / Wire / Block / Granule

Looking for high-quality Indium materials for laboratory use? Look no further! Our expertise lies in producing tailored Indium materials of varying purities, shapes, and sizes. We offer a wide range of Indium products to suit your unique requirements. Order now at reasonable prices!

High Purity Lead (Pb) Sputtering Target / Powder / Wire / Block / Granule

Looking for high-quality Lead (Pb) materials for your laboratory needs? Look no further than our specialized selection of customizable options, including sputtering targets, coating materials, and more. Contact us today for competitive pricing!

Alumina (Al2O3) Ceramic Crucible For Laboratory Muffle Furnace

Alumina ceramic crucibles are used in some materials and metal melting tools, and flat-bottomed crucibles are suitable for melting and processing larger batches of materials with better stability and uniformity.

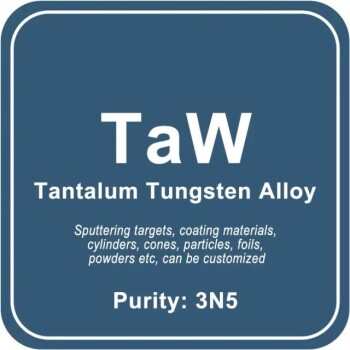

Tantalum Tungsten Alloy (TaW) Sputtering Target / Powder / Wire / Block / Granule

Looking for high-quality Tantalum Tungsten Alloy (TaW) materials? We offer a wide range of customizable options at competitive prices for laboratory use, including sputtering targets, coatings, powders, and more.

Related Articles

XRF Pelletising for Solid Samples Tips and Tricks

X-ray fluorescence (XRF) analysis is a non-destructive analytical technique used to determine the elemental composition of solid, liquid, and powdered samples.

Transmission Electron Microscopy Sample Preparation: From Basics to Practical Skills

Detailed guide on TEM sample prep, covering cleaning, grinding, polishing, fixation, and covering techniques.